ATEX

ATEX, from the French word Atmosphères Explosibles, meaning “explosive atmospheres”, is the European Union’s authoritative certification for safety in explosive atmospheres. ATEX certified equipment is safe for use in environments where explosive gases, dusts and liquids are present. This article will introduce the definition of ATEX certification, marking, scope of application and certification process.

What is ATEX Certification?

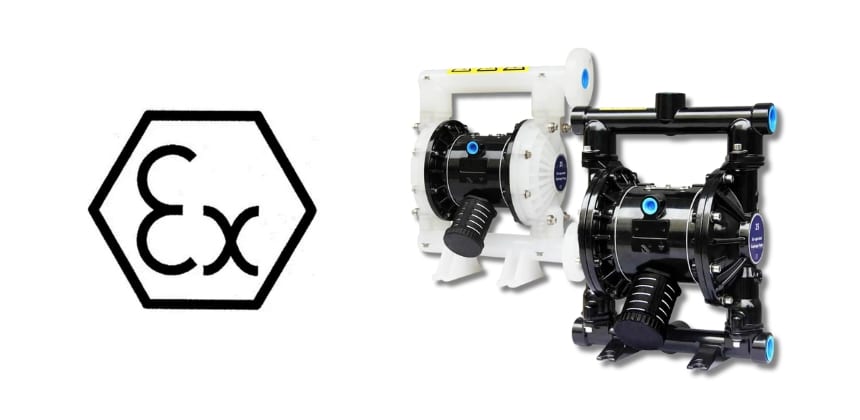

What does The ATEX Mark look like?

The ATEX marking usually contains an “Ex” symbol indicating that the equipment is suitable for use in explosive atmospheres. Typical symbols include:

- Ex: indicates that the equipment is suitable for use in explosive atmospheres.

- Equipment group: Class I for mines, Class II for other locations.

- Class and Zone: e.g. 1G, 2G, 3G, indicates the hazard class to which the equipment applies.

For example, the symbol Ex II 1G indicates that this equipment is applicable to Zone 0 (gas environment) in non-mining areas, which is the highest safety level.

ATEX is a mandatory EU directive for equipment and protective systems used in explosive atmospheres.ATEX contains two main directives:

ATEX Equipment Directive (2014/34/EU): sets standards for the manufacture of equipment and protective systems for use in explosive atmospheres and ensures that products are designed, tested and produced in accordance with safety requirements.

ATEX Workplace Directive (1999/92/EC): requires risk control measures to protect workers in workplaces where explosive substances are present.

What Industries and Products is ATEX Certification Critical for?

ATEX certification is particularly important for the following industries:

- Chemical and oil & gas: Operating environments are highly susceptible to explosive atmospheres as the liquids and gases handled are mostly flammable.

- Pharmaceutical and food processing: Often involves volatile solvents or fine powders with a potential risk of explosion.

- Mining and tunneling: Mines contain large amounts of methane gas and equipment must be highly explosion-proof.

- Energy production and storage: Power stations and fuel depots involve large quantities of flammable and explosive materials and have very high safety requirements.

ATEX certification applies to a wide range of products, including electrical equipment (e.g. motors, sensors), non-electrical equipment (e.g. pumps, valves), control and protection systems (e.g. alarms, explosion-proof control boxes) and other process equipment. In particular, air-operated diaphragm pumps(KES15/20 1/2″ 3/4″ Plastic Diaphragm Pump) and fluid transfer pumps, when used to transfer flammable liquids in industries such as the chemical and oil and gas industries, must comply with ATEX standards to prevent explosions due to friction or static-induced sparks. ATEX certified pumps have been rigorously designed and tested to work stably in high-risk environments, avoiding sparks or overheating during operation and ensuring that the pumps are safe to use.

Types of Explosion Protection and their Applications

To ensure the safety of equipment in explosive atmospheres, ATEX certification offers several types of protection against ignition:

- Explosion-proof enclosure (Ex d): A robust enclosure designed to prevent the flame of an internal explosion from spreading outwards.

- Increased safety (Ex e): Enhanced insulation of equipment to reduce the risk of sparks and high temperatures.

- Intrinsically Safe (Ex i): Designed to prevent sparks or heat overload through electrical current limiting, usually for signaling circuits.

- Positive pressure protection (Ex p): Prevents the entry of external flammable gases by maintaining a positive pressure inside the equipment.

ATEX Equipment Certification Process

The ATEX equipment certification process is rigorous and standardized and typically includes the following steps:

- Risk assessment: Determine the area of use and the risk level of the equipment in an explosive atmosphere and establish the appropriate design criteria.

- Design and production: Based on the results of the risk assessment, ATEX-compliant equipment is designed and explosion-proof materials and processes are used.

- Testing and verification: Rigorous testing by an independent certification body ensures that the equipment meets all the requirements of the ATEX standard.

- Certification: After passing the tests, the equipment is ATEX certified for use in the specified explosive atmosphere.

- Regular inspection and maintenance: The equipment is regularly serviced and inspected during use to ensure that it is always in a safe condition.

Meaning of ATEX Certification

ATEX certification is of great value to both manufacturers and users. For manufacturers, ATEX certification means that their products comply with European safety standards and are competitive in the marketplace; for users, ATEX certification ensures that equipment is safe for use in high-risk environments. Especially for equipment used in flammable and explosive environments, such as pneumatic diaphragm pumps, valves and motors, ATEX certification greatly reduces the risk of accidents and safeguards production safety and the health of personnel.

Summary

ATEX certification is an essential EU safeguard for the safety of equipment and personnel in high-risk environments. For equipment that needs to operate in explosive atmospheres, the ATEX standard ensures that it is designed, manufactured and used safely. Whether for pneumatic diaphragm pumps in the chemical or oil and gas industries, or for other equipment with an explosive risk, ATEX certification reduces the risk of accidents and guarantees the safety and reliability of the production process. Choosing equipment that complies with ATEX standards is therefore not only a legal requirement, but also a responsible choice for your employees and the environment in which you operate.

AOBL is committed to providing high quality ATEX certified equipment, especially in air operated diaphragm pumps and other fluid transfer products (electric diaphragm pumps, sanitary diaphragm pumps, progressive cavity pumps, magnetic drive pumps, vertical centrifugal pumps, chemical pumps and spare parts), with superior technology and strict quality control to ensure that the equipment is able to work stably in all kinds of complex environments. Choosing AOBL is choosing safety, stability and efficiency. We are committed to bringing our customers high quality products and professional services to help companies gain higher productivity and more robust security in high-risk environments.