What Is A Progressive Cavity Pump?

What is a progressive cavity pump?

Progressive cavity pump is a type of positive displacement pumps, also known as single screw pump, eccentric screw pump, cavity pump, helical rotor pump, and PC pump. It relies on the mutual meshing of screw and liner to produce volume changes in the suction and discharge chambers to transport liquids. Often used in heavy duty industries, progressive cavity pumps are capable of handling high viscosity sludge and slurries, ensuring low shear handling and accurate and repeatable pulsation-free flow rates.

How does progressive cavity pump work?

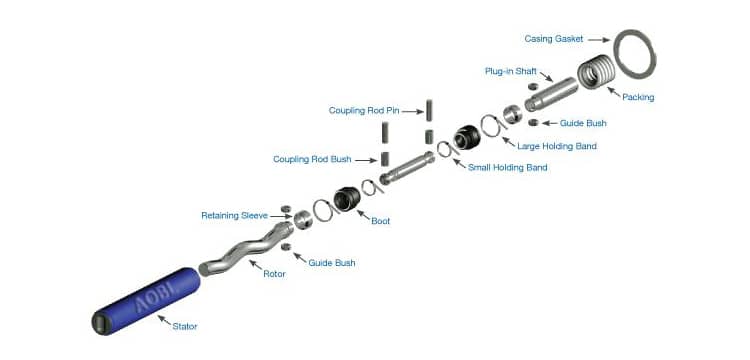

It is a kind of internal meshing closed screw pump, the main working parts are composed of the liner (stator) with double-ended helical cavity and the single-ended helical screw (rotor) meshing with it in the stator cavity.

When the input shaft through the universal joint to drive the rotor around the center of the stator for planetary rotation, the stator – rotor vice will be continuously engaged to form a sealed cavity, these sealed cavity volume is unchanged for the uniform axial movement of the conveying medium from the suction end of the stator – rotor vice conveying to the end of the pressure out of the inhalation of the media into the closed chamber of the media flow through the stator without being stirred and destroyed.

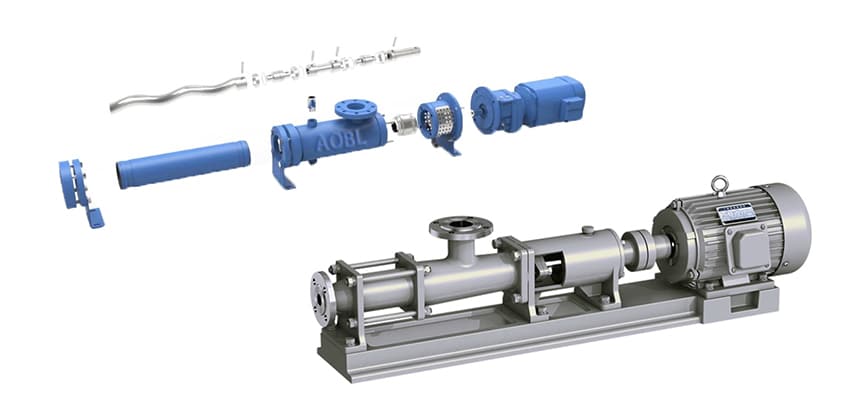

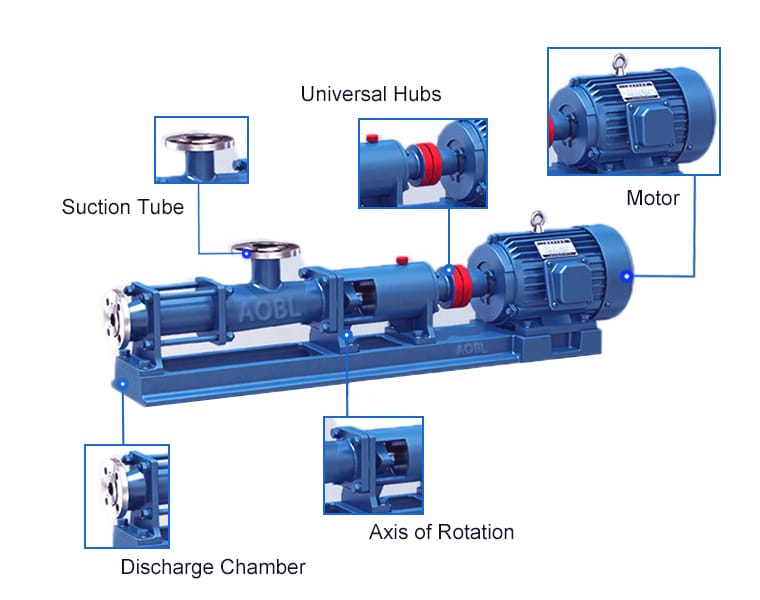

Progressive cavity pump parts

The main components of the progressive cavity pump are discharge chamber, rotor, stator, universal joint, intermediate shaft, suction chamber, shaft seal and bearing housing components.

Rotor

The rotor is the key component of a progressive cavity pump, also known as a screw. It is a cylindrical shaft paired with helical threads around it, which can generate strong suction and discharge pressure as it rotates. The shape and size of the rotor varies according to the different types of pumps and working conditions.

Stator

The stator is a supporting part of the rotor, which is usually in the shape of a tube and fixed in the case of the pump. When the rotor rotates inside the stator, the inner surface of the stator and the surface of the rotor closely fit together to form a closed chamber, thus generating strong suction and discharge pressure.

Casing

The case is the shell of the single screw pump, supporting and protecting the rotor and stator and other internal components. It is usually machined from cast iron or steel plate with good strength and corrosion resistance.

The above three are the basic parts, their role is to ensure the normal operation of the pump, improve the service life and efficiency of the pump.

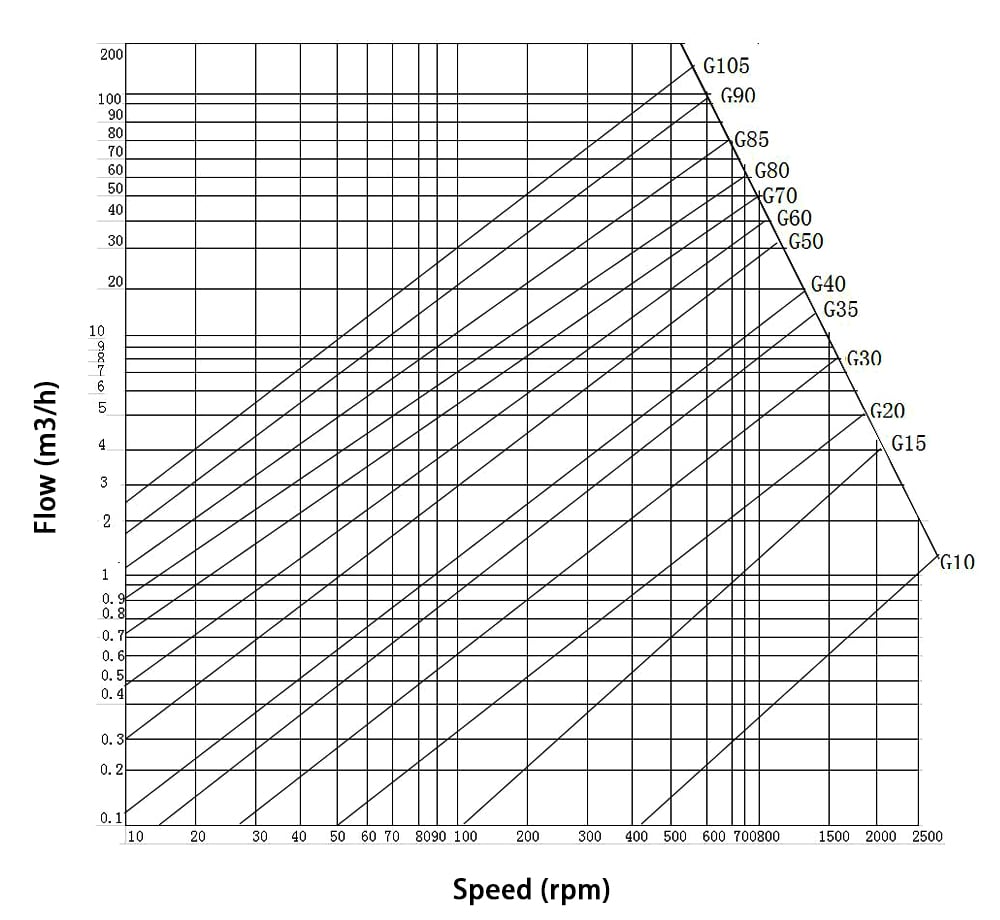

Progressive cavity pump design and curve

The design structure of the progressive cavity pump is characterized by simplicity and compactness. It mainly consists of pump casing, screw, bearings, seals and transmission devices. The pump casing is usually made of cast iron, stainless steel or other corrosion-resistant materials with good sealing and rigidity. The screw is in the shape of a single helix and forms a sealing working chamber by cooperating with the inner surface of the pump casing. The screw is usually made of stainless steel or hard alloy with high wear and corrosion resistance. Bearings are used to support and position the screw to ensure its proper operation. The selection of seals is very important to ensure the sealing performance and working efficiency of the pump. The transmission can be a motor, gearbox or other transmission device for driving the rotation of the screw.

The progressive cavity pump performance curve is linear, indicating the ability of the unit to handle liquids of different viscosities, which has little effect on the pump performance, with the flow rate being proportional to the speed.

Characteristics of progressive cavity pump

Advantages

- High self-priming capacity, can transport liquids containing solid particles, commonly used in sewage installations to transport wet sludge, etc.

- The flow rate does not change with the change of pressure head, but only depends on the size and speed of moving parts.

- The rated discharge pressure is not directly related to the rotational speed and size of the moving parts, and is mainly restricted by the sealing performance, structural strength and the power of the prime mover.

- Simple structure, few parts, easy to disassemble.

- Pump internal leakage loss is small, so the pump efficiency is high.

Disadvantages

- The pump is more demanding in terms of machining and assembly.

- The pump is very sensitive to changes in the viscosity of the liquid.

- The pump body produces violent vibration and noise when working.

Progressive cavity pump uses

- Municipal engineering: quantitative dosing in water supply plant, transportation and discharge of sedimentation sediment, transportation of sludge after dewatering in sewage plant, feeding of filter press, addition of chemicals, such as flocculant, milk of lime and other chemical solutions.

- Shipbuilding industry: the ship in the transportation of fuel oil, sweeping warehouse, remove floating oil on the sea, discharge of sewage, dirty oil to shore and loading and unloading of various materials.

- Petroleum industry: extracting and conveying crude oil and thick oil from land and sea oil fields, extracting and conveying oil, gas, sand and other mixtures. In recent years, especially successful extraction of underground dry meters of crude oil and water mixtures, coal fields in the coal field gas and water mixtures, thus greatly reducing the machine city oil mining, coal field gas mining costs, when the oil field to the late stage, the use of screw pumps to the formation of polymer injection to increase the recovery rate of the oil field.

- Pharmaceuticals, daily chemical: a variety of viscous slurry, emulsion, various ointments cosmetics and other conveyance.

- Food brewing industry: conveying food raw materials, dairy materials, carbonated beverages and seasonings, straw thick starch, cooking oil, honey, fruit pulp, fruit juice, cream, minced fish, minced meat, fermentation viscous liquid, thick wine lees, grain product residue, the recommendation of sauces, slurries, slurries and viscous liquids containing chunks of solids and so on.

- Construction industry: cement mortar, lime slurry, paint and other paste spraying and transportation.

- Non-metallic minerals: ceramic industry production of slurry, porcelain oil, refractory clay suspension transportation, the production of coal water slurry and the use of transportation. The transportation of raw material slurry in the production of high territory.

- Mining industry, the mine containing solid particles of underground and dirty slurry water and other discharge to the ground.

- The chemical industry: a variety of suspensions, emulsions, polymers, dyes, organic materials, inorganic materials, oils and fats, a variety of colloidal slurry, synthetic fibers, viscose liquid, nylon powder and liquid transport.

- Printing, paper industry: high viscosity ink wallpaper PVC polymer plastic paste and various concentrations of pulp, cotton pulp, grass pulp, paint, white liquid black liquid and alkali recovery in the heavy oil, short fiber slurry delivery.

When to use a progressive cavity pump?

Progressive cavity pumps are particularly suitable when the conveying medium is of medium to high viscosity, or contains abrasive solids. Other types of pumps are usually unable to convey such fluids well for long periods of time due to their construction.

Single screw pump selection

The selection of progressive cavity pumps mainly consider the following parameters:

- Pressure determination for progressive cavity pumps

The maximum output pressure of the progressive cavity pump is determined according to the number of liner stages, i.e., the number of leads of the liner (stator). Due to the different conditions of the conveying medium, for the medium containing serious abrasive, according to the requirements of the conveying pressure to select the appropriate number of stator stages. - Selection of rotational speed of progressive cavity pump

Single screw pump due to its structural characteristics, most of the use in the transmission of higher viscosity liquids and liquids containing particles, so the choice of its speed is very critical. For the selection of the speed of the progressive cavity pump is mainly based on the abrasiveness of the medium and the viscosity of the medium. - Single screw pump liner rubber material selection

Single screw pump liner for rubber products, but also a single screw pump wearing parts, it’s good or bad choice, directly affect the life of the liner, the normal life of the liner for 3-6 months, if the choice is not appropriate, the liner may fall off from the steel pipe or rubber off the block. - Material combination selection

Transportation of different properties of the medium, the need for different material combinations. - Performance

General single screw pump performance table or characteristic curve are 20 ℃ water as the medium (viscosity of 1cst) when the data, for conveying different viscosity under the flow rate and shaft power is different. - Shaft seal

According to the need and conveying medium, mechanical seal and packing seal can be used for two kinds, and these two structures are interchangeable. - Pump drive mode

As the progressive cavity pump is a low-speed pump, the pump drive mode is more, generally there are low-speed motor direct connection (6-stage, 8-stage), gear motor drive, stepless speed motor drive and other ways.

AOBL progressive cavity pump

Progressive cavity pumps are the highest share of the progressive cavity pumps market. This is due to its wide range of applications and unique features. Some of the well-known brands in the progressive cavity pumps market are Mono, Seepex, Netzsch, Sulzer, PCM, AOBL, and many more.

AOBL is one of the leading manufacturers of progressive cavity pumps and offers a wide range of PC pumps including conventional, open hopper, metering, and stainless steel food grade pumps. AOBL screw pumps feature a variety of rotor/stator geometries and a wide range of engineered fittings in the right combinations to meet the requirements of your application, are cost-effective and low-maintenance and are available in a wide range of sizes and materials.