AOBL provides additional protection in optimizing pump and system performance for efficiency and for your critical equipment. Our air-operated double diaphragm (AODD) pump spare parts, repair kits and accessories are tested and approved. When used with your AOBL pump, they can improve your system performance and extend the life of your pump.

Advantages of AOBL Genuine Kits

- Reduce the frequency of maintenance

- Increase service life

- Extend uptime

- Save time and money

- Improve pump performance and productivity

- Reduce failure rates

- Protects ancillary equipment during fluid transfer

- Precision pump control and air efficiency

AOBL accessories include

- Pulsation damper: Helps provide a virtually pulsation-free discharge stream for more consistent pressure while reducing system vibration and noise

- Air filter regulator lubricator: Protects the pump air valve by removing solid and liquid contaminants from the air line, while providing additional precise pump control

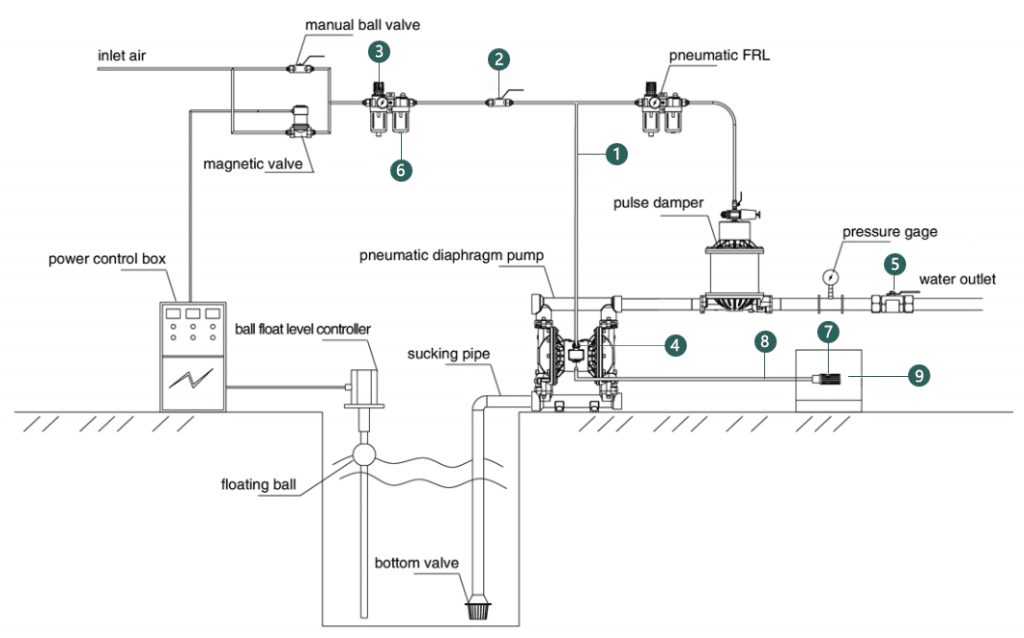

Accessories installation process diagram

- Gas Pipeline

- Cuprum Ball Valve

- Air Pressure Regulator

- Intake Pipe Quick Connection

- Leak Type Cuprum Ball Valve

- Pneumatic FRL(Filter regulator lubricator)

- Muffler

- Exhaust Pipe

- Container For Exhaust