What is a Diaphragm Pump and How Does it Work?

What is a diaphragm pump?

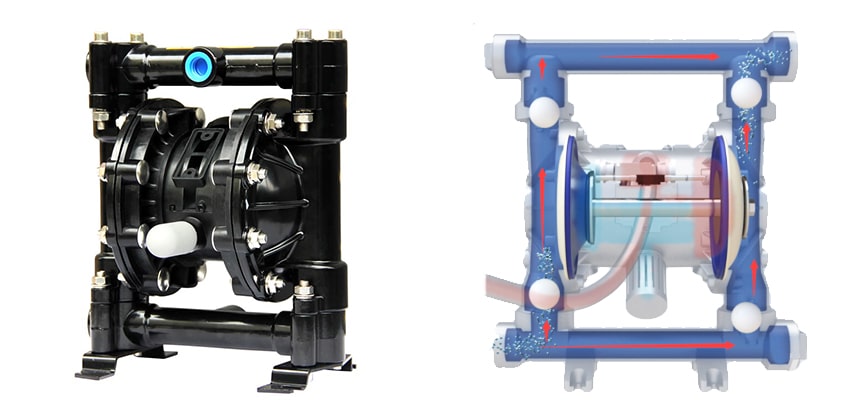

A diaphragm pump is a positive displacement reciprocating pump that uses compressed air as a power source. Pneumatic valves direct the flow of compressed air back and forth between the two sides of the pump. Also known as air operated double diaphragm (AODD) pumps, pneumatic diaphragm pumps.

Air operated diaphragm pumps can convey all types of viscous liquids, liquids containing suspended solids, and corrosive chemicals. This is due to their unique construction design and wide range of diaphragm materials.

How does a diaphragm pump work?

Diaphragm pump construction

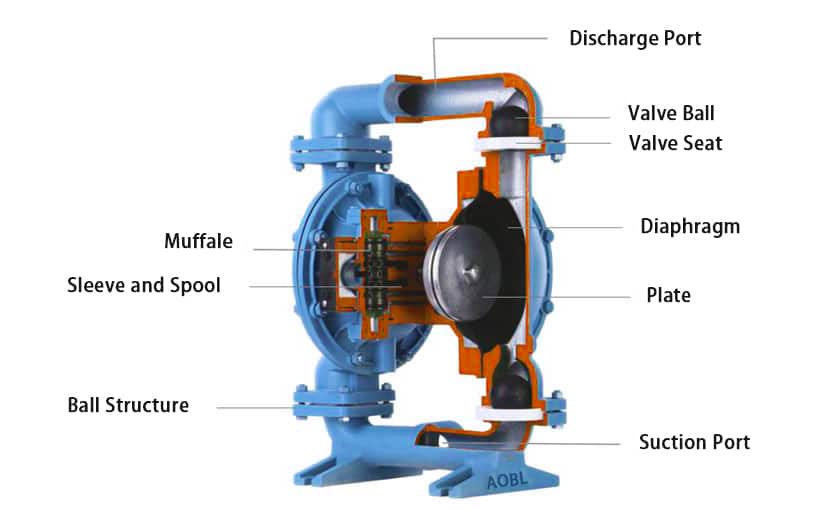

An air operated diaphragm pump consists of the following 6 main components:

- Pneumatic valve: by the motor body, main valve, reversing valve three parts. This part is a device that converts the energy of the compressed air into the kinetic energy of the reciprocating motion, and is a main part of the diaphragm pump.

- Fluid cover: combined with the motor body (or gas cover) to form a cavity.

- Diaphragm assembly: diaphragm connecting rod, diaphragm gasket, diaphragm bolt and the corresponding O-type sealing ring, diaphragm composition. The diaphragm separates the cavity into a gas cavity and a flow cavity, and the diaphragm component moves reciprocally under the action of the gas motor to form a pressure difference between the gas cavity and the flow cavity.

- Ball valve components: by the ball and ball seat and the corresponding O-type sealing ring. It acts as a check valve.

- Inlet and outlet pipe: only plays the role of fluid in the pump body into and out of the pipe.

- Silencer: plays a role in reducing the noise generated when the pump works.

Working principle of diaphragm pump

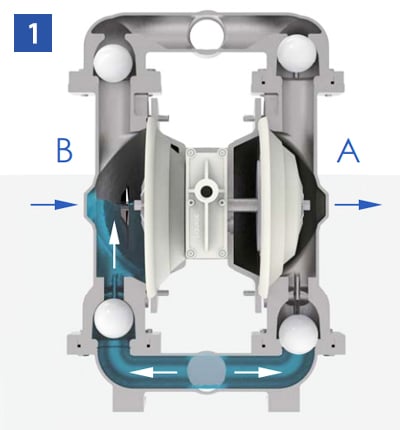

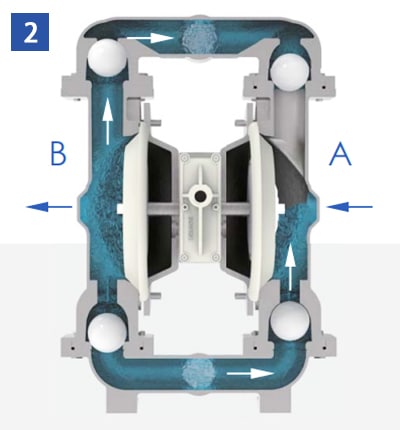

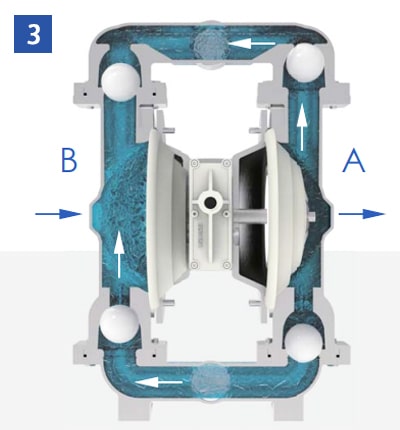

The working principle of pneumatic diaphragm pump is based on compressed air driven diaphragm reciprocating motion in the pump body, thus realizing the suction and discharge of liquid. The specific operation process is as follows, there are 3 stages:

- When compressed air enters the pneumatic part of the AODD pump, it first drives one diaphragm to move in the other direction, creating negative pressure in one chamber of the pump, which opens the suction valve and draws liquid into the pump.

- Subsequently, the compressed air through the pneumatic part of the pneumatic valve, drive another diaphragm in the opposite direction. At this time, the original negative pressure chamber within the diaphragm movement, so that the liquid under pressure through the discharge valve out of the pump.

- With the continuous switching of the pneumatic valve in the pneumatic section, the two diaphragms reciprocate alternately, realizing continuous and uninterrupted liquid delivery.

What is a Double diaphragm pump used for?

Air operated double diaphragm pumps have a wide range of applications in many fields, such as:

- Water treatment: sewage treatment, waste water recycling and other water treatment fields.

- Chemical: Transport a variety of corrosive, flammable, explosive and toxic chemical liquids.

- Petroleum: Transportation of crude oil, diesel oil, lubricating oil and other petroleum products.

- Pharmaceutical: Transport all kinds of liquid medicine, raw materials and biological products.

- Food: Conveying juice, alcohol, seasonings and other food liquids.

- Minerals: Transporting pulp, wastewater and other liquids in the mining field.

Pneumatic diaphragm pump troubleshooting

Although diaphragm pumps are rugged and can be used in almost any application, they can still fail. The problems and countermeasures are listed below:

| Problem | Cause | Solution |

| Pump is leaking out. | Valve cap or valve cap screw is loose. | Tighten the screws. |

| Pump will not cycle, or cycles once and stops. | Air valve is stuck or dirty. | Disassemble and clean air valve. Use filtered air. |

| Check to see if the valve ball is severely worn and/or wedged in seat or manifold. | Replace ball and seat. | |

| Check to see if the valve ball is wedged into seat, due to over pressurization. | Install Pressure Relief Valve. | |

| Dispensing valve clogged. | Relieve pressure and clear valve. | |

| Pump operates erratically. | Clogged suction line. | Inspect; clear. |

| Sticky or leaking balls. | Clean or replace. | |

| Diaphragm (or backup diaphragm) ruptured. | Replace diaphragms. | |

| Restricted exhaust. | Remove restriction. | |

| Pilot valves damaged or worn. | Replace pilot valves. | |

| Air valve damaged. | Replace air valve. | |

| Air valve gasket damaged. | Replace air valve gasket. | |

| Air supply erratic. | Repair air supply. | |

| Exhaust muffler icing. | Use drier air supply. | |

| Air bubbles in fluid. | Suction line is loose. | Tighten. |

| Liquid leakage from the pump. | Pump not matched to rigid piping, exceeding allowable manifold loads. | Installation of pulsation dampers. |

In fact, the diaphragm pump failure and corresponding solutions are very many, more details please see the air diaphragm pump troubleshooting.

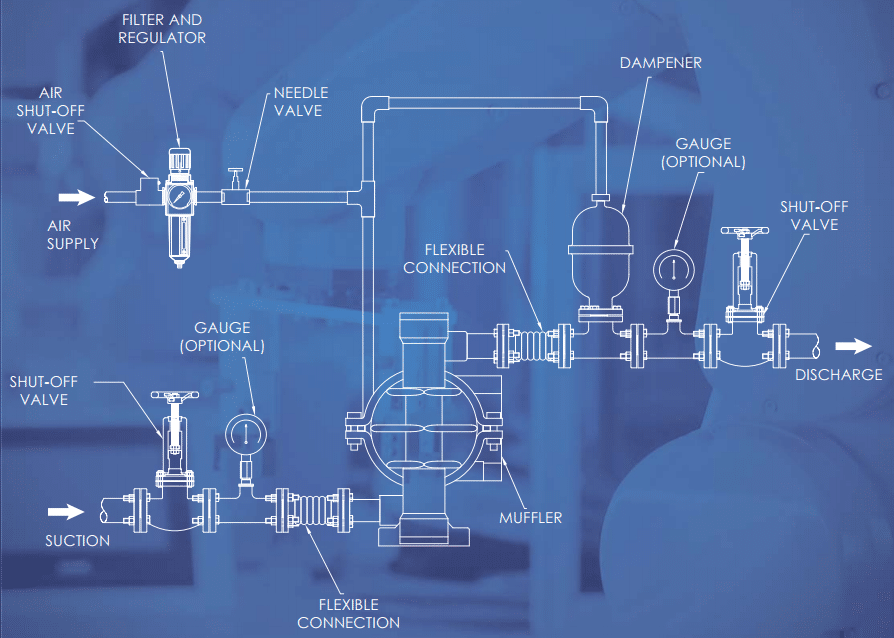

Air operated diaphragm pump installation

Install and start

The pump is placed close to the water source as far as possible, so that the suction pipe line is very short, the number of configuration parts is reduced, and the pipeline specifications are not reduced. In order to extend the life of the diaphragm, the pump should be as close as possible to the liquid being pumped.

Supply air

The air inlet of the pump is connected to an air source with sufficient capacity and pressure load design requirements. If the gas supply line is a hard line, connect a short hose between the pump and the line to reduce distortion.

Check the diaphragm pump before operation

Before work, check all the fixed objects to prevent loosening, and tighten the loose places to avoid leakage.

Intake and start

When starting, the air valve is opened about one-half to three-fourths of a turn. After starting, open the air valve to increase the air flow until the required flow rate is reached.

Diaphragm pump advantages and disadvantages

Advantages

- Air operated diaphragm pumps are relatively small, easy to move, simple and economical to install.

- The use of pneumatic diaphragm pumps in flammable and explosive environments is not only reliable and stable, but also inexpensive.

- In harsh environments, due to the large amount of impurities in the sewage and the complex composition of the pipeline, it is easy to clogging phenomenon, resulting in excessive load on the motor, easy to damage the motor. Air operated diaphragm pumps are easy to pass particles through and can adjust the flow tube to prevent clogging.

- Can be used to convey chemically relatively unstable fluids

- When handling hazardous and corrosive materials, diaphragm pumps can completely isolate the material from the outside world. Effectively prevent accidents

Disadvantages

- Pressure cannot be increased and is limited by the pressure of the gas source

- Noise and pipe vibration are particularly noticeable at high atmospheric levels

- Diaphragms have a shorter life than screw pumps and are more prone to damage

- Most diaphragm pumps can only be used in small systems, as the flow rate is usually not very high.

- Pulsing at the fluid outlet

Buy diaphragm pump

Diaphragm pump selection

Air-operated diaphragm pumps can handle all types of fluids, thanks to a wide range of material and configuration options. Choosing the right AODD pump can significantly enhance your application process and save you money.

AOBL is the world’s leading manufacturer of diaphragm pumps and is part of the GL Environment Group. Supplies include air driven diaphragm pumps, electric operated diaphragm pumps and accessories. Pumps are available in sizes ranging from a 1/4 inch to 3 inch, with material options ranging from plastic to metal, just to meet the needs of your various fluid transfer applications. Feel free to contact the AOBL technical and sales team to help you meet the challenges of your various conveying applications.