Chemical pumps are suitable for corrosive liquid and chemical transfer. They are also known as acid and alkali resistant pumps. It has extra strong corrosion resistance and has the advantages of high mechanical strength, no aging, no toxin decomposition, etc. It is the ideal equipment for conveying all kinds of strong and weak acids.

AOBL is a professional chemical pump manufacturer and supplier of all kinds of chemical process pumps. Pumps that are incompatible with chemicals may cause swelling, dissolution or embrittlement, ultimately leading to leaks and failures. We offer tried and tested products and solutions for your chemical process, ensuring that our chemical transfer pumps will provide you with a long, trouble-free service life.

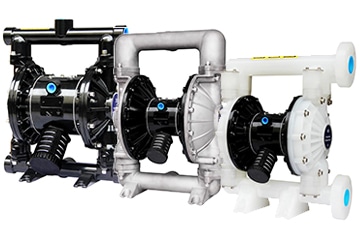

Chemical Transfer pump products

Chemical pump types

Classification based on chemical pump materials

- Stainless steel chemical pumps are widely used in petroleum, chemical, metallurgy, synthetic fiber, pharmaceutical, food, synthetic fiber and other departments for conveying alkaline corrosive media.

- Fluorine plastic chemical pumps are used for conveying any acidic and alkaline corrosive media.

- Cast iron chemical pumps are used for industrial and urban water supply and drainage, and can also be used for irrigation and drainage of farmland and orchards for conveying clear water or other liquids with physical and chemical properties similar to clear water.

According to the chemical pump use classification

- Process pumps: including feed pumps, reflux pumps, circulation pumps, flushing pumps, sewage pumps, supplemental pumps, output pumps and so on.

- Utility pumps: including boiler pumps, cool water tower pumps, fire pumps, deep well pumps for water sources.

- Auxiliary use pumps: including lubricating oil pumps, sealing oil pumps, hydraulic transmission pumps, etc.

- Pipeline transfer pumps: pumps for oil pipelines, pumps for loading and unloading trucks, etc.

According to the working principle, structure classification

- Vane pump: through the pump shaft rotation drives a variety of impeller blades to the liquid with centrifugal force or axial force, conveying liquid to the pipeline or container, such as centrifugal pumps, vortex pumps, mixed flow pumps, axial pumps.

- Positive displacement pumps: the use of the pump cylinder volume of continuous changes in the pump to transport liquid pumps, such as reciprocating pumps, piston pumps, gear pumps, diaphragm pumps and screw pumps.

- Other forms of pumps: the use of electromagnetic transmission of liquid conductive body state of solenoid pumps; the use of fluid energy to transport liquid pumps, such as jet pumps, air lifters and so on.

Categorized according to the conditions of use

- High-flow and micro-flow pumps: flow rate of 300 m³/min and 0.01 L/min respectively

- High-temperature and low-temperature pumps: high temperature up to 500 ℃, low temperature to -53 ℃

- High-pressure pumps and low-pressure pumps: high pressure up to 200 MPa, vacuum degree of 2.66–10.66 kPa (20-80mmHg)

- High-speed pumps and low-speed pumps: high speed up to 24,000 RPM, low-speed 5-10 RPM

- Accurate metering pump: flow measurement accuracy of ± 0.3%

- High viscosity pumps: viscosity up to thousands of parsecs Pa.s

Chemical pump functions

- In-plant transfer: chemical pumps are used to transfer raw liquid from storage tanks, troughs or other equipment to process equipment such as reactors, mixing tanks, evaporators and so on.

- Circulation system: chemical pumps are used to circulate and transport liquids to maintain the stable operation of process systems, such as cooling water circulation systems, heating systems, etc.

- Transfer and distribution: chemical pumps can be used to transfer liquids from one process unit to another, or to distribute and allocate liquids between different equipments.

- Waste liquid treatment: chemical pumps can be used to transfer and treat waste liquids, waste water, waste liquids, etc., to help purify and treat waste liquids generated in chemical processes.

Outstanding chemical resistance for long life

Multiple pump options

We offer a wide range of chemical process pumps in different materials and types to meet the needs of our customers for all types of applications.

Customizable Fluid Sections

Easily customize your fluid selection with AOBL’s fluid transfer pumps with housings that can handle all fluids, including corrosive and abrasive.

Proven reliability

We design and manufacture acid and alkali resistant pumps to withstand the harshest operating environments. The best materials and the highest quality standards.