Reciprocating Pump

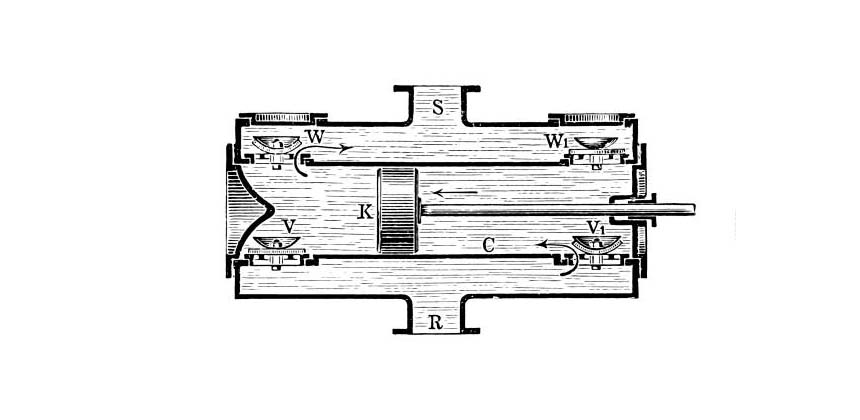

General principle of operation of reciprocating pumps

Suction phase

- When a reciprocating pump begins to operate, the piston or plunger is in a position away from the cylinder, creating an area of negative pressure.

- The intake valve opens, allowing external liquids or gases to flow into the cylinder from the intake port.

- As the reciprocating pump moves, the piston or plunger moves closer to the cylinder, reducing the volume and allowing the intake valve to close. At this point, the intake port is closed, stopping backflow.

Discharge phase

- The piston or plunger begins to move outward, increasing the volume of the cylinder and creating an area of high pressure.

- The discharge valve opens, allowing fluid in the high-pressure region to be pushed out through the discharge port.

- As the reciprocating pump continues to move, the piston or plunger moves outward, compressing the fluid in the discharge phase.

Reciprocal cycle

- The piston or plunger continues its reciprocating motion, alternating suction and discharge phases.

- Each cycle of reciprocating motion produces a pulsating fluid output, a characteristic unique to reciprocating pumps.

Reciprocating pumps work similarly to piston engines, but in this case the primary focus is on the movement of fluid rather than the conversion of mechanical energy. Reciprocating pumps are used in scenarios where precise flow rates and high-pressure fluid delivery are required, such as chemical processing, injection equipment, and pressure testing. Their simple and reliable working principle makes them widely used in many industrial and commercial applications.

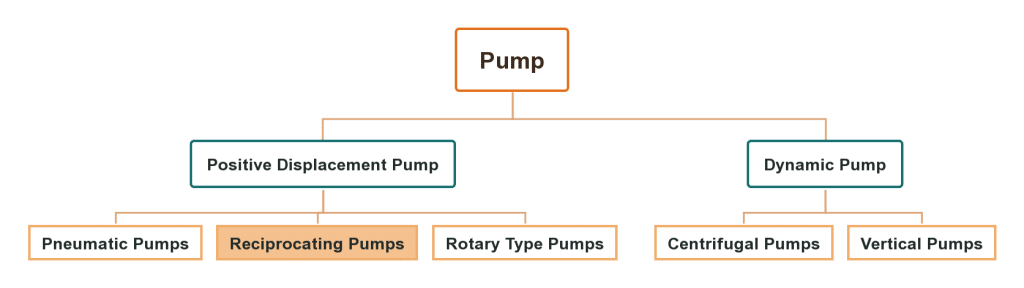

In which category of pumps do reciprocating pumps belong?

Reciprocating pumps belong to the classification of positive displacement pumps (PDPs). Positive displacement pumps are a class of pumps that operate on the principle of moving a fixed amount of fluid per operating cycle, independent of changes in discharge pressure. Reciprocating pumps realize this operating principle through the reciprocating motion of a piston, plunger, or diaphragm, which allows fluid to be drawn in and discharged. For this reason, reciprocating pumps are classified as one of the subcategories in the classification of positive displacement pumps.

Reciprocating pumps and centrifugal pumps differ significantly in their principle of operation and field of application. Reciprocating pumps discharge a fixed amount of fluid by means of a reciprocating motion and are used in scenarios where precise flow control is required, such as chemical dosing and coating. Centrifugal pumps, on the other hand, push fluids into a centrifugal force field with the help of rotating impellers, and are suitable for high flow and low pressure requirements, such as in industry, water supply and drainage. The differences in construction and performance between these two types of pumps determine their unique advantages in different applications.

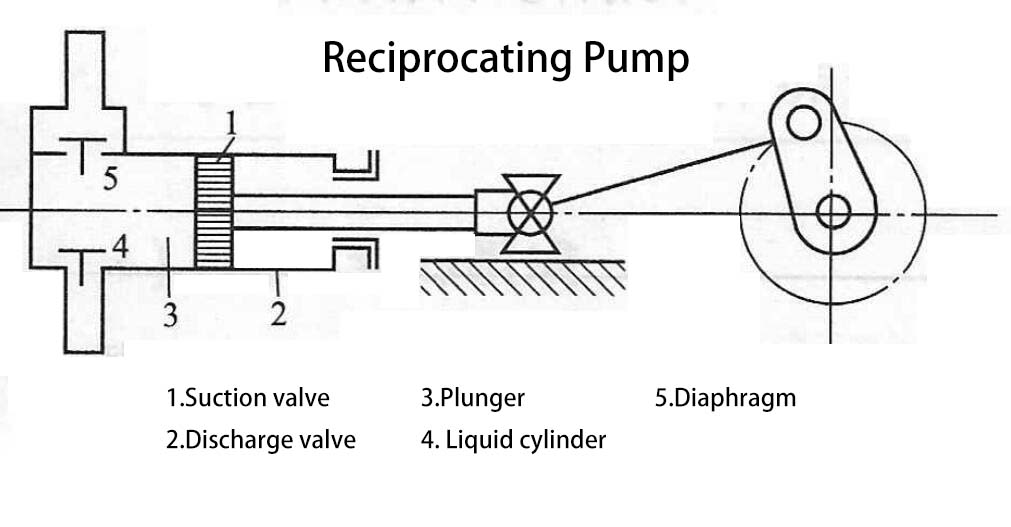

What types of reciprocating pumps are there?

- Single acting reciprocating pumps

In each stroke, the piston or plunger pumps fluid in only one direction. Suction and discharge are accomplished in a single stroke(eccentric screw pump). This type of pump is usually used for low-flow, high-pressure applications, such as some precision fluid transfer equipment. - Double acting reciprocating pumps

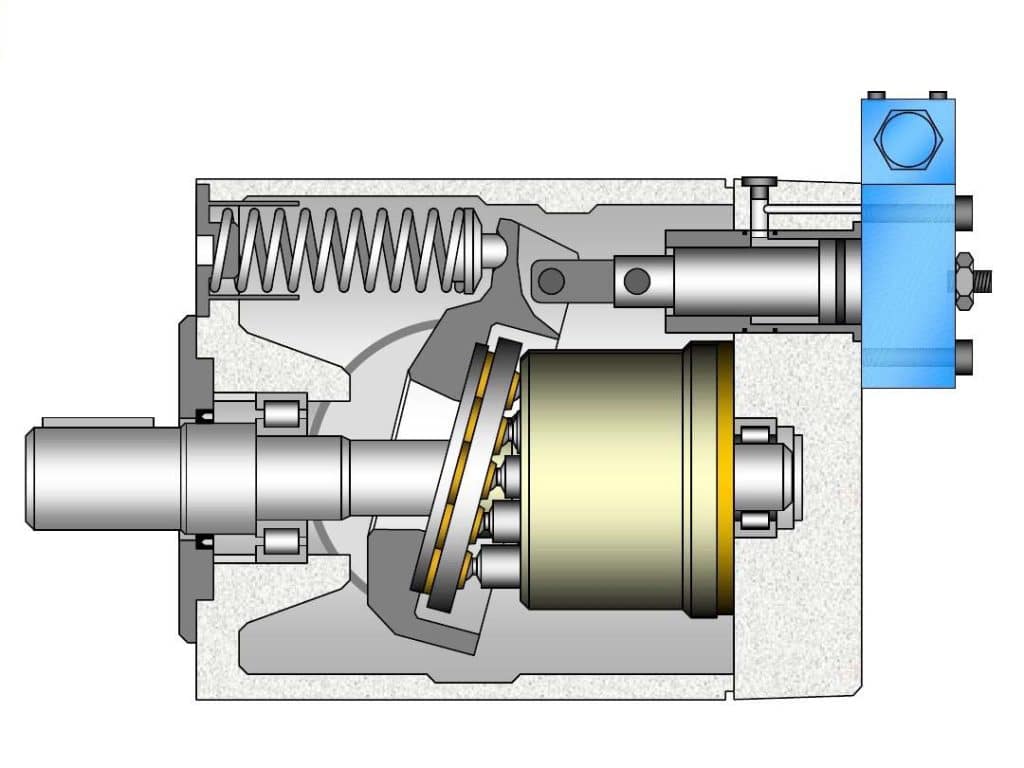

In each stroke, the piston or plunger in two directions alternately pumping fluid. Suction and discharge take place in two different chambers of the same cylinder, so each stroke can produce fluid output. Double-acting reciprocating pumps typically provide a more consistent flow output and are suitable for medium-flow, high-pressure applications. - Hydraulic reciprocating pumps

Hydraulic Reciprocating Pump uses the pressure of the liquid to control the movement of the piston or plunger, thus realizing the pumping of liquid. This type of pump is common in industrial equipment and systems that require hydraulic power. - Plunger pumps

Plunger pump is a special type of reciprocating pump, its working principle is similar to the piston pump. The difference is that the plunger usually has a smaller diameter, so that in the same cylinder size, can achieve higher working pressure. - Piston pumps

Piston pumps use a piston to achieve reciprocating motion and are usually suitable for low to medium pressure applications. The design of piston pumps can be adjusted as needed to meet different flow and pressure requirements.

Does the pneumatic pump belong to the reciprocating pump?

The answer is yes, Pneumatic Pumps can often be categorized as a type of Reciprocating Pumps. Pneumatic pumps utilize the compression and expansion of gases to control the reciprocating motion of a diaphragm, piston, or plunger to pump liquids or gases. Since the working principle of pneumatic pumps involves reciprocating motion, it belongs to the category of reciprocating pumps.

An air operated diaphragm pump is a common example of an air operated pump that uses the pressure of compressed air to drive the reciprocating motion of a diaphragm to pump a liquid. This type of pump (KES50 2″Plastic Diaphragm Pump) is commonly used in environments where electrical equipment needs to be avoided, in hazardous environments, or where frequent start-stop operations are required. Because the air operated diaphragm pump operates in a manner consistent with the characteristics of a reciprocating pump, it is a subcategory of reciprocating pumps.

What are the usual failures of reciprocating pumps and how can they be solved?

| Failure Type | Possible Causes | Solutions |

| Leakage Issue | Worn seals, poor sealing, valve damage | Regularly inspect and replace worn seals; ensure proper valve operation and installation |

| Valve Problems | Valves sticking, malfunction, damage | Clean valves to ensure proper operation; replace valves if necessary |

| Unstable Flow | Unstable piston/plunger, seal issues, gas ingress | Check motion component status for smooth operation; eliminate gas ingress |

| Pump Body Wear | High pressure, high-speed operation, liquid corrosion | Use appropriate materials; regularly inspect and maintain worn pump bodies |

| Incompatible Liquid | Use of unsuitable fluid | Choose appropriate fluids to prevent corrosion and damage |

| Drive Issues | Drive device failure, power supply issues | Inspect drive devices for normal operation; check stability of power supply |

| Overheating | Excessive friction, high-pressure operation | Ensure proper lubrication and cooling systems, reduce friction, mitigate overheating risk |

| Vibration and Noise | Unbalanced motion, loose components, improper installation | Adjust and calibrate pump components; ensure correct installation, reduce vibration and noise |

The type of reciprocating pump is usually used in which field?

Reciprocating pumps are typically used in applications that require precise flow control and reliable liquid transfer. Their fixed reciprocating motion allows them to excel in applications such as chemical dosing, pharmaceutical manufacturing, coating, food processing(Sanitary Diaphragm Pump), and environmental water treatment(Open Hopper Screw Pump). By ensuring that a fixed amount of liquid is discharged during each operating cycle, reciprocating pumps ensure precise ingredient mixing, pharmaceutical formulations, coating thicknesses, and fine liquid control for environmental water treatment needs in these areas.

Summary

Overall, the reciprocating pump is a common and important industrial pump that plays a key role in the transfer of liquids and pressure increase. Its simplicity, reliability and multiple applications make it an indispensable piece of equipment in many industries.

AOBL provides fluid handling equipment to customers and industries worldwide, including pneumatic diaphragm pumps, electric diaphragm pumps, sanitary pumps, FDA pumps, filter press pumps, screw pumps, chemical pumps, magnetic pumps and other equipment. Feel free to contact us.