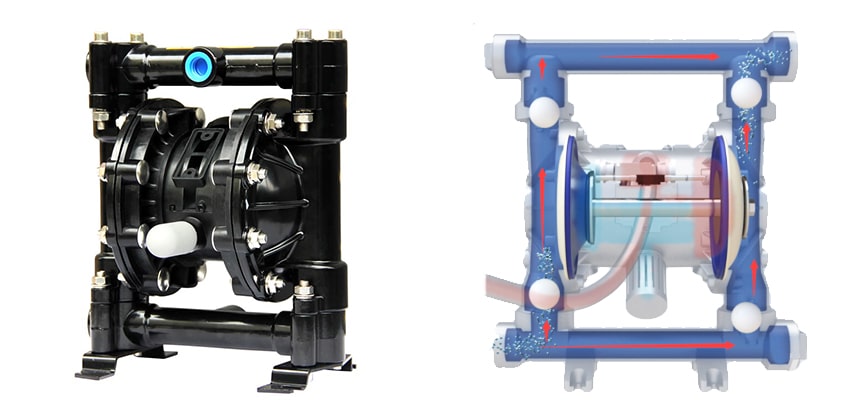

AOBL offers a complete line of repair kits to keep your diaphragm pump running at peak efficiency and maximize its service life.

Spare Parts Contents

- Diaphragm

- Valve Ball

- Valve Seat

- O-Ring

There are many spare parts for air-operated diaphragm pumps, and it usually starts with selecting the right diaphragm. Diaphragms are critical to the safety and efficiency of AODD pump operation. The right diaphragm will improve pump reliability, performance and service life, and reduce downtime.

We offer diaphragms in a variety of materials for a wide range of industry applications, from aggressive chemicals to highly abrasive materials to extreme operating temperatures. AOBL ensures that your unique application fully meets the requirements for the best diaphragm to optimize chemical compatibility, life, flow, temperature limitations, wear resistance and cost.

diaphragm options

| Material |

|---|

| Viton |

| PTFE |

| Santoprene |

| Buna-N |

| Polyurethane |

How to choose a suitable diaphragm?

All process and application parameters need to be carefully identified and included in the analysis. Important selection factors are the following.

Chemical resistance

Compatibility of the material with the fluid being pumped

Temperature range

Ability to remain flexible at low temperatures and not deteriorate at high temperatures

Abrasion resistance

Ability to withstand wear and friction caused by contact with solids and particles in the pumped fluid

Resilient life

Expected life of the diaphragm before it needs to be replaced

Cost

Total cost of ownership is determined by a variety of factors such as initial price, rated flex life of the application, and downtime and diaphragm replacement labor costs

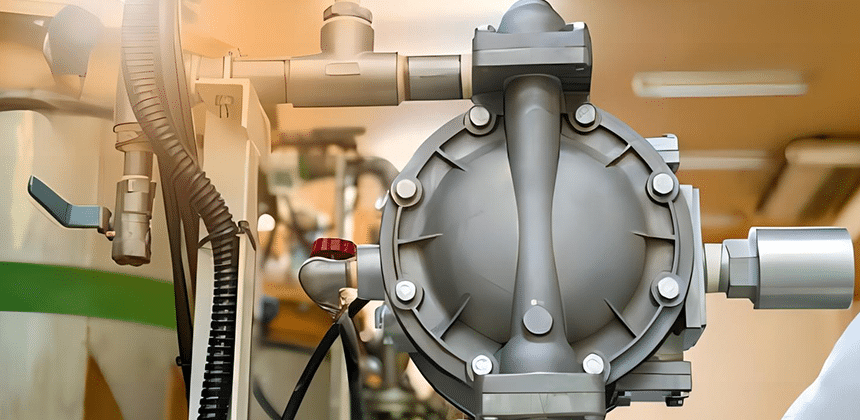

| Brand | AOBL |

| Maintenance kit contents | Diaphragm, valve ball, valve seat, O-ring, sealing ring, air valve |

| Diaphragm temperature resistance | -40 F (-40 ℃) to 350 F (176.6 ℃) |