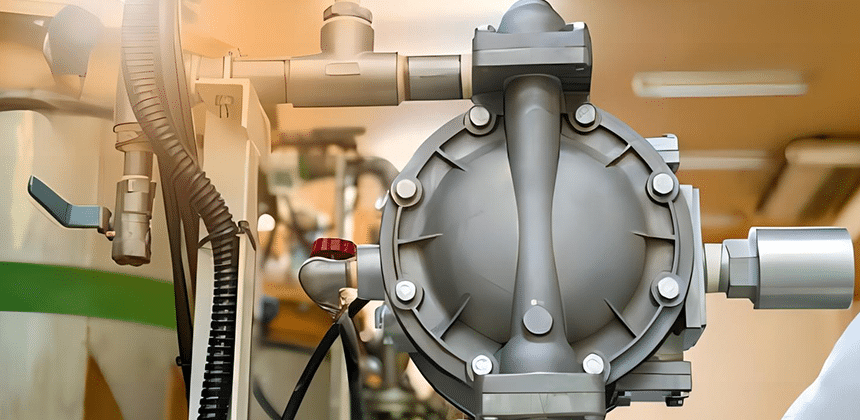

The AOBL pulsation damper works with compressed air and diaphragms to automatically set the correct pressure to minimize pulsation. Helps eliminate material blistering, material pulsation, hydraulic shock or material splash.

This feature is critical in applications where vibration minimization and control of pipe hammer is required to protect piping systems and downstream instrumentation.

How pulsation dampers work?

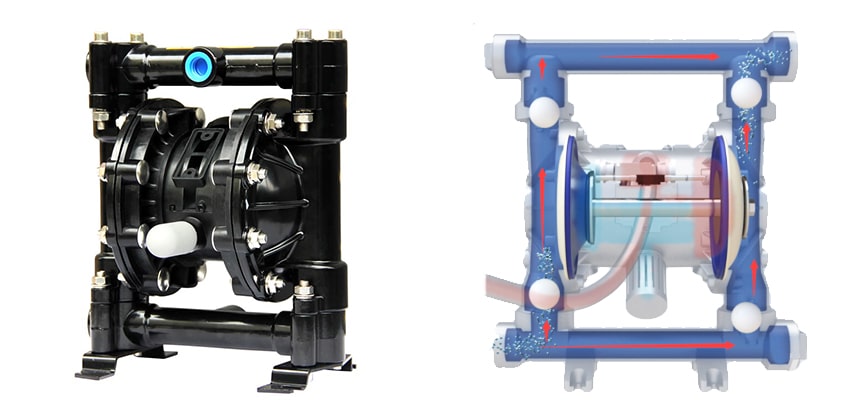

Air operated double diaphragm pumps generate fluid pulsations during operation. The pulsation damper uses a flexible diaphragm to separate the fluid chamber from the compressed air chamber. As the fluid pulses into the fluid chamber, it moves the diaphragm upward into the compressed air chamber. The force of the compressed air slows the displacement of the diaphragm, effectively dampening fluid pulsation while damping vibration and noise.

Features

- Provides excellent surge suppression

- More stable pressure

- Reduced vibration and noise

- Protects other system components

- Simple in-line installation

- Broad chemical compatibility

- Improves pump efficiency

- Extended pump life

Applications

- Drum or package filling

- Pumping from mixing tanks to balancing tanks

- Applications requiring laminar flow

- CIP systems

- Applications with flow meters or other accurate in-line instrumentation

- Applications with quick closing valves

| Brand | AOBL |

| Diaphragm material | Santoprene/PTFE |

| Shell material | PVC/PP/PVDF, 304/316L/Carbon steel |

| Connection mode | Thread (standard)/Flange (optional)/Tee (optional) |

| Inflation pressure | Automatic regulation |

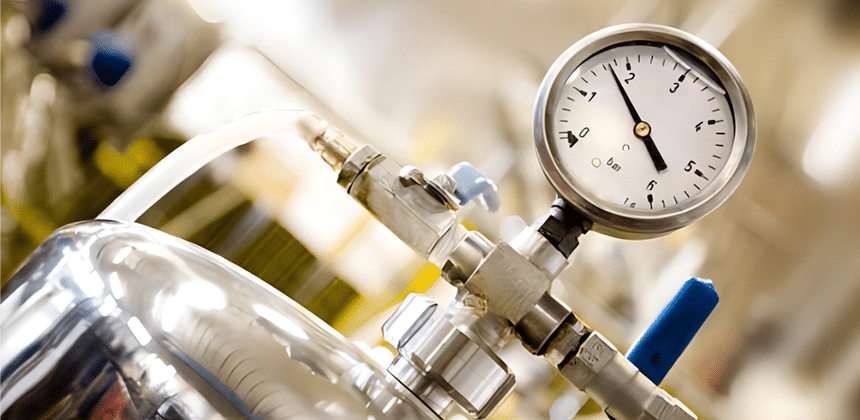

| Maximum pressure | 6.9 Bar, 8Bar |