Water Velocities Of Pumps

Water velocity in pumps is a critical aspect of fluid dynamics that directly impacts the efficiency and performance of pumping systems. Understanding water velocity is essential for optimizing system efficiency, reducing energy consumption, and preventing potential issues like pipe erosion or cavitation.

Velocity Of Water Flow In The Pumping System

The velocity of water flow is the speed at which water moves through a pipe or channel, usually measured in meters per second (m/s) or feet per second (ft/s). In a pumping system, the flow rate of water is affected by the performance of the pump, the typee of pumps, and the design of the system piping.

Pump Flow and Water Velocity

Flow rate is the key characteristic of a pump and is usually measured in liters per second (L/s) or gallons per minute (GPM). The rate of water flow can be calculated from the flow rate using the following formula:

V=A/Q

- V = Water Velocity (m/s)

- Q = Flow Rate (m³/s or L/s)

- A = Cross Sectional Area of The Pipe (m²)

Effect of Pump Type on Water Velocity

1. Centrifugal Pumps

Effects on water flow rate

Centrifugal pumps increase the kinetic energy of water by rotating the impeller. The water is thrown to the outside by the centrifugal force of the rotating impeller and discharged from the outlet of the pump casing, creating a flow. Higher water flow velocities are usually produced, especially with high flow rates and low pressure heads. The higher the pump speed and impeller size, the higher the water flow rate. High flow velocities for high flow, low-pressure situations.

Effects on water flow rate

Captures and discharges a fixed volume of liquid by means of a piston, diaphragm, or gear. Low flow rate, pumps a fixed volume of liquid at a time, with a low flow rate, but high pressure and a steady flow rate.

Precise control: Flow rate can be precisely controlled, suitable for scenarios that require quantitative delivery.

2. Screw Pumps

Effects on water flow rate

Screw pumps are a type of positive displacement pump that conveys liquid along a helical path by the rotation of a screw. The rotation of the screw creates multiple sealed chambers in which the liquid is propelled to maintain a continuous flow. The resulting flow velocity is typically low and high pressure resistant but due to the spiral motion, the flow is continuous and steady, making it suitable for handling highly viscous liquids and applications requiring precise flow control.

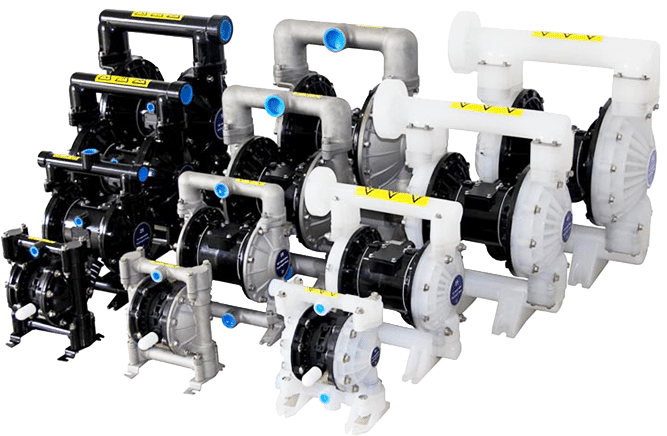

3. Diaphragm Pumps

Effects on water flow rate

Diaphragm pumps change the volume of the pump chamber by the reciprocating motion of the diaphragm, thus pushing the liquid to flow. Diaphragm pumps do not have impellers or screws, but instead push water by physical compression. Diaphragm pumps have a relatively low flow rate, but the flow rate can be controlled as needed by adjusting the frequency of pump strokes. The ability to handle liquids containing suspended solids, corrosive liquids, and high-viscosity liquids allows for greater flexibility in flow rates.

4. Axial Flow Pumps

Principle of operation

Axial flow pumps cause water to flow in the direction of the pump’s axis by means of helical vanes. Unlike centrifugal pumps, axial flow pumps do not increase the kinetic energy of the water but are primarily used to increase the flow rate of the water. Capable of producing higher water flow rates, it is, however, suitable for low pressure head applications. Similar to centrifugal pumps, axial flow pumps provide a continuous, steady flow.

The Importance of Controlling The Speed of Water Flow

- Excessive speeds can cause problems such as increased friction losses, pipe erosion, and noise.

- Too low a speed may result in deposits, poor flow, or cavitation in the pump.

Summary

Selecting the right pump and configuring the system to achieve the optimal water velocity can enhance performance, improve energy efficiency, and prolong the lifespan of the equipment.

Taking into account factors such as the type of pump, system requirements and the characteristics of the fluid being conveyed, AOBL pump manufacturers offer a range of pumps to effectively manage water velocities and ensure reliable, efficient pumping operations across a wide range of industries. Click on the website link to contact us now