Knowledge of Centrifugal Pump

Centrifugal pumps play an important role in water supply, drainage, cooling, and many other applications as indispensable liquid transfer devices in modern engineering.

Working principle of centrifugal pumps

Basic structure of the centrifugal pumps

Centrifugal pump is a commonly used liquid transportation equipment, its basic structure includes an impeller, shaft pump body, and other key components.

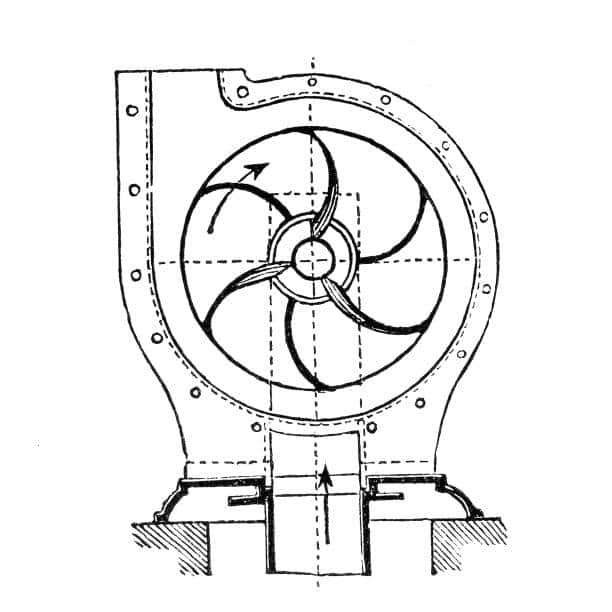

- Impeller: The impeller is the centerpiece of a centrifugal pump and usually consists of multiple vanes. When the impeller rotates, the blades generate centrifugal force, which draws liquid from the inlet and pushes it to the outlet.

- Shaft: The shaft connects the motor to the impeller, transmits power, and rotates the impeller. Shafts are usually made of strong materials to ensure stable operation of the impeller.

- Pump casing: The pump casing is the housing structure that holds the impeller and the liquid. It is designed to direct the flow of liquid through the impeller and ensure smooth liquid flow. The pump body usually has inlet and outlet ports to allow liquid to enter and exit.

- Sealing arrangement: To prevent liquid leakage and maintain the sealing performance of the pump, centrifugal pumps are usually equipped with a sealing arrangement, such as a mechanical seal or packing seal.

- Bearing Structure: The support structure is used to support the operation of the bearings and impellers, and absorb the force generated by the rotary motion. It usually consists of bearings and support frames.

Centrifugal force generation and fluid transport processes

The centrifugal force generated by the rotation of the impeller is one of the key principles of centrifugal pump operation. The rotation of the impeller generates centrifugal force, which causes the liquid to move outward along the axis of the impeller. When the centrifugal force is sufficiently high, the liquid is drawn in from the inlet forced through the impeller, and ultimately conveyed to the outlet. This process can be understood as the liquid being forced towards the outlet of the centrifugal pump by the centrifugal force.

This centrifugal force can be generated by Newton’s first law to understand: according to Newton’s first law, the liquid will maintain its original state of inertia, i.e., without external forces to maintain static or uniform linear motion. When the impeller rotates, the blade contacts the liquid and drives it, causing the liquid to accelerate. Since the liquid has mass, according to Newton’s second law, this acceleration produces a force directed away from the center of the impeller, the centrifugal force. This centrifugal force causes the liquid to be pushed out in the radial direction of the impeller, thus realizing the process of the liquid being sucked in from the inlet and transported through the impeller to the outlet.

Centrifugal pumps operate on a similar rotating centrifugal force mechanism, in which the flow of liquid is driven by the impeller’s centrifugal force. This mechanism makes centrifugal pumps an efficient and reliable device for transferring liquids and is widely used in various industrial and civil applications.

Application areas of centrifugal pumps

Industrial Applications:

- In water supply systems, centrifugal pumps are usually used to provide urban water supply, industrial production water, and agricultural irrigation. They can effectively transport water from the water source to where it is needed and maintain a stable water pressure and flow rate.

- In drainage systems, centrifugal pumps are used to remove sewage, wastewater, and rainwater, ensuring the proper functioning of sewage treatment plants, sewers, and drains. They pump wastewater quickly and efficiently from low to high or distant treatment facilities, reducing the risk of water pollution and waterlogging.

- In cooling systems, centrifugal pumps are used in industrial production, air conditioning systems, and power plants. They are capable of pumping a cooling medium (usually water or coolant) from a cooling tower or cooling equipment and delivering it through cooling pipes to the equipment or area that needs to be cooled to control the temperature and keep the equipment functioning properly.

In addition, centrifugal pumps play an important role in fire protection systems. They are installed as fire pumps in buildings, factories, and other locations to provide sufficient water pressure and flow to extinguish fires or provide emergency water in the event of a fire.

Agricultural applications:

- In agricultural irrigation, centrifugal pumps are often used to pump water from a water source (e.g., a river, lake, or well) and then transport the water through a piping system to a field or orchard for rationed and timed irrigation of crops. This helps to provide sufficient water and nutrients to promote plant growth and development and improve agricultural yield and quality.

- In aquaculture, centrifugal pumps are often used to provide a suitable water environment to sustain the survival and growth of fish and other aquatic organisms. They can be used to circulate water, increase oxygenation, filter waste, and keep water clean, thereby increasing the efficiency of aquaculture and the growth rate of aquatic organisms on aquaculture farms. In addition, centrifugal pumps can help farmers control key parameters such as temperature, pH, and dissolved oxygen in the aquaculture water to ensure a stable and suitable environment for aquaculture.

Architectural applications:

- In a building water supply system, centrifugal pumps are installed in the pump room or the basement of the building and are responsible for pumping the city water supply or a self-supplied source of water to the water tanks or the pipe network inside the building. This ensures stable water pressure inside the building and meets the domestic and productive water needs of the users.

- In terms of drainage systems, centrifugal pumps are often used in drainage pumping stations or basements to pump sewage, wastewater, and rainwater from the building from a low point to the city sewer or sewage treatment plant. This helps to keep the building environment clean and hygienic, avoiding flooding and sewage overflows, while protecting the environment from pollution.

- In addition, centrifugal pumps are one of the indispensable equipment in urban infrastructure development. They are widely used in the construction of urban infrastructure for water supply, drainage, cooling, and firefighting. By transferring water from the source to where it is needed, centrifugal pumps help to ensure the normal operation of all parts of the city, meet the needs of people’s daily lives and industrial production, and promote the sustainable development of the city.

Characteristics of centrifugal pumps

Centrifugal pumps are efficiently designed for fast and efficient liquid transfer. Its excellent design structure and working principle enable it to suck the liquid from the inlet with high-speed rotation, and then accelerate the liquid to the outlet through the centrifugal force of the impeller. This design ensures that the liquid maintains a stable flow rate and pressure during the conveying process, which improves conveying efficiency and reduces energy consumption.

At the same time, centrifugal pumps are simple in structure, reliable in operation, and easy to maintain and use. Due to its few major components and simple structure, the failure rate is low and the maintenance cost is relatively low. Operators only need to carry out basic maintenance and upkeep, such as regular checking of lubrication and tightening of bolts, to ensure the normal operation of centrifugal pumps.

Types of centrifugal pumps

- Single-stage centrifugal pumps: Single-stage centrifugal pumps are the simplest type of centrifugal pump, consisting of a single impeller, and are typically used in applications with low to moderate head and flow requirements, such as domestic water supply, small irrigation systems, etc.

- Multi-stage centrifugal pumps: Multi-stage centrifugal pumps consist of multiple impellers in cascade to provide higher heads and flow rates. They are suitable for applications requiring higher heads, such as water supply for high-rise buildings, high-pressure transfer in industrial production, and irrigation systems.

- Mixed-flow pumps: Mixed-flow pumps combine the characteristics of centrifugal and axial flow pumps, with impellers that have both centrifugal and axial flow forces. They are suitable for applications requiring medium to high head and high flow rates, such as river pumping stations, drainage pumping stations, and turbine generators.

- Axial flow pumps: Axial flow pumps convey liquids primarily through the axial movement of the impeller and are suitable for applications requiring high flow rates but lower heads, such as drainage, pumping stations, and water management.

- Deep well pumps: Deep well pumps are designed to extract groundwater in deeper wells. They are usually vertically mounted, have long pumping depths and smaller diameters, and are suitable for water supply in areas with deeper water tables.

Limitations of centrifugal pumps

Need for starting energy: Centrifugal pumps usually require an external energy source to function properly, such as an electric motor or diesel engine. This means that in the event of a power outage or lack of energy, centrifugal pumps will not be able to operate, which may affect the associated production or water supply system.

Not suitable for high-viscosity liquids: Centrifugal pumps are less efficient when transferring high-viscosity liquids and may suffer from clogging. Because their operating principle is designed for low to medium viscosity liquids, they are less suitable for transporting high viscosity liquids and other types of pumps or additional pre-treatment measures need to be considered.

Maintenance and precautions for centrifugal pumps

Maintenance method:

- Regular cleaning: clean the external and internal parts of the centrifugal pump, including the pump body, impeller, and inlet/outlet piping, etc. regularly to remove accumulated dirt and deposits and keep the pump in good condition.

- Lubrication: Regularly lubricate the pump’s bearings and seals to minimize friction and wear and prolong the life of the equipment. Use appropriate lubricant or grease to keep the bearings well-lubricated.

- Inspection of impeller: Inspect the condition of the impeller periodically to ensure that its surface is smooth and undamaged, and to remove any foreign matter that may be attached. If the impeller is found to be damaged or deformed, replace it in time to ensure the normal operation of the pump.

Notes:

- Safe operation: When using centrifugal pumps, you should strictly abide by the relevant safety regulations to ensure the safety of the operators. Avoid touching the running pump to avoid accidental injury.

- Correct installation: When installing the centrifugal pump, make sure that it is firmly fixed on the ground or foundation and kept horizontal. Correct installation can reduce vibration and noise and improve the stability and safety of the equipment.

- Regular inspection: Regularly inspect and maintain the centrifugal pump to find and solve potential problems in time to ensure the normal operation of the equipment. In particular, pay attention to whether there is any leakage or corrosion of the pump body and pipeline.

Summary

Centrifugal pumps, as an important liquid transfer equipment, provide reliable liquid transfer solutions for the engineering field with the advantages of high efficiency and speed, wide applicability, stable structure, and easy maintenance. Through regular maintenance and attention to safe operation, centrifugal pumps can be ensured to operate stably for a long period, providing reliable support for industrial production and urban infrastructure construction.

AOBL offers various types of centrifugal pumps, also pneumatic diaphragm pumps, electric diaphragm pumps, sanitary diaphragm pumps, screw pumps, magnetic drive pumps, and chemical pumps. Please contact us if you need any further information.