Sealless Pump

In modern industry, fluid transfer systems are a key part of ensuring efficient and safe production. However, conventional pumps are often prone to problems such as leakage or seal failure when faced with high temperatures, high pressures or corrosive fluids. With the continuous development of technology, seal-less pumps have emerged as an important tool to solve these problems.

What’s sealless pump?

Sealless pumps are pumps without conventional seals and are typically used to handle the transfer of high temperature, high pressure or toxic chemicals. Due to the absence of conventional mechanical seals, Sealless pumps reduce the risk of leakage and can increase safety and reliability in harsh environments. Common types include:

- Magnetically driven pumps: Power is transmitted by magnetism, avoiding the need for traditional mechanical seals, and are suitable for conveying hazardous, corrosive or difficult-to-handle liquids.

- Seal-less positive displacement pumps: Such as progressive cavity pumps or diaphragm pumps, which utilize a built-in structural design that avoids the need for seals and are suitable for conveying highly viscous liquids or slurries.

Specificities

- High safety: Prevents leakage of hazardous chemicals and ensures safe operation in sensitive applications.

- Low maintenance costs: No seals to wear out, reducing failure rates and downtime.

- Environmentally friendly: Minimizes the environmental impact of fluid leaks.

- High durability: Can handle corrosive chemicals and high pressure environments

Applications

- Chemical industry: for transportation of corrosive or hazardous liquids.

- Oil and gas: for the transportation of volatile or expensive liquids.

- Pharmaceutical industry: for sterile and uncontaminated fluid handling.

- Food and beverage industry: for applications with high hygiene requirements.

Difference Between Seal-Less and Sealed Pumps

| Features | Seal-less pumps | Sealed Pumps |

| Sealing method | No mechanical seals, magnetic drive or shielded motors | Mechanical or packing seals are used |

| Leakage risk | No leakage | Risk of leakage and regular maintenance |

| Maintenance costs | Low maintenance requirements and long service life | High maintenance costs due to frequent replacement of seals |

| Applicable media | Toxic, hazardous, corrosive or demanding fluids | For common liquids or where leakage is not critical |

Seal-less pumps are recommended if the fluid is hazardous, corrosive, or if leakage requirements are stringent; sealed pumps may be more cost-effective for general fluid transfer or limited budget scenarios.

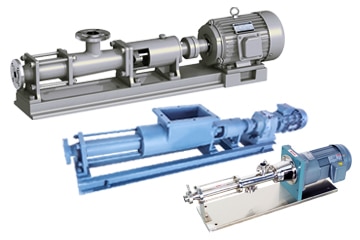

Pump Types For Seal-less Pumps

- Magnetic Drive Pump

Magnetic Drive Pumps are the most common type of seal-less pump, utilizing magnetic force to transmit power and avoiding the traditional mechanical seal construction. The interaction between the rotor inside the pump and the external drive is achieved by magnetic force, which results in the transfer of fluid. With no seals in direct contact, they effectively reduce the risk of leakage. AOBL magnetic drive pumps have a comprehensive range of magnetic drive seal-less pumps that can be used in most extreme climates and in a wide range of applications to help revolutionize your process.

- Diaphragm pumps

Diaphragm pump generates pressure through the movement of elastic diaphragm to push the liquid flow. Due to its special design structure, diaphragm pumps do not require traditional mechanical seals. Diaphragm pumps are suitable for handling highly viscous liquids or fluids containing particles.

- Screw Pump

Progressive Cavity Pumps utilize a single or double helix structure to propel the fluid forward through the rotation of the screw. This pump type is designed to avoid the use of seals and is suitable for fluids with high viscosity or containing solid particles.

Advantage: It can stably transport high viscosity liquids and fluids containing particles.

Applications: Widely used in petroleum, chemical, food processing and other industries.

- Liquid Ring Pump

Liquid ring pump is a liquid ring through the working principle of rotary gas or liquid transportation pump. The pump body has a liquid ring in the rotation, the use of gas and liquid pressure difference to realize the transport.

Summary

Seal-less pumps are gradually becoming the equipment of choice in the field of fluid transportation due to its advantages of no leakage, high efficiency and low maintenance. Although it still faces certain challenges, with the advancement of technology and the growth of market demand, the future application of seal-less pumps is promising and worthy of attention and investment from various industries.

AOBL is a main in-house provider of industrial pump solutions, specializing in a wide range of pump types. Their products are used in a number of industries, especially where there is a need to avoid leaks and handle corrosive, hazardous liquids. If you are looking for efficient and low maintenance pump equipment, AOBL is a good choice, welcome to contact us.