M3/min To CFM Conversion

In the field of water treatment and pumping equipment, it is important to understand the conversion of flow units. Different regions and industries use different flow units, making it a challenge to understand and compare data properly. This article will help you know how to convert flow units from cubic meters per minute (m³/min) to cubic feet per minute (cfm) and explore what this means in practice in pump applications.

Basic concepts of flow units

- Cubic meters per minute (m³/min) is a unit of flow in the International System of Units (SI) that expresses the number of cubic meters passing per minute. It is commonly used in industry and science, especially when describing the flow of liquids and gases.

- Cubic feet per minute (cfm) is an imperial unit used primarily in the United States and a few other countries. It expresses the number of cubic feet passing per minute and is commonly used to describe airflow and other gas flows.

Unit Conversion Formula

The formula for converting flow rate from cubic meters per minute to cubic feet per minute

1 m³/min=35.3147 cfm

This conversion factor is based on the fact that 1 cubic meter equals 35.3147 cubic feet. Therefore, to convert m³/min to cfm, simply multiply the m³/min value by 35.3147.

Illustrative Calculations

Suppose a pump has a flow rate of 5 m³/min. convert this to cfm as follows

- 5 m³/min×35.3147 cfm/m³/min=176.5735 cfm

- Therefore, a flow rate of 5 m³/min equals approximately 176.57 cfm.

| CFM | M3/min |

| 1 | 35.3147 |

| 2 | 70.6294 |

| 3 | 105.9441 |

| 4 | 141.2588 |

| 5 | 176.5735 |

| 6 | 211.8882 |

| 7 | 247.2029 |

| 8 | 282.5176 |

| 9 | 317.8323 |

| 10 | 353.147 |

Practical Application of Pumps In Water Treatment

Design and Selection

Equipment selection: When designing a water treatment system, accurate flow data is critical to selecting the proper pumps and other equipment. For example, if a system has a flow requirement of 300 cfm, an engineer can use the conversion formula above to determine the required pump flow rate of approximately 8.5 m³/min.

Performance optimization: Understanding and accurately converting flow units can help optimize pump performance, ensuring that the system operates at its best, reducing energy consumption and operating costs.

Pump Equipment Maintenance and Optimization

Troubleshooting: Understanding flow unit conversions can help technicians accurately assess equipment performance during routine maintenance and troubleshooting. For example, if a pump’s actual output is less than the expected m³/min, technicians can convert it to cfm to compare performance data provided by the manufacturer.

System upgrades: When upgrading or expanding a system, flow unit conversion ensures that the new equipment is compatible with the existing system and avoids system failure due to inconsistent units.

Suitable Pump Selection

Centrifugal pumps: Centrifugal pumps commonly used in applications requiring high flow rates and low-pressure heads, such as raw water transfer and water purification systems. They are suitable for most water treatment applications and are highly efficient and simple to maintain.

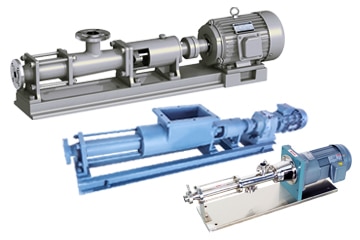

Progressive cavity pumps: Progressive cavity pumps are suitable for transferring viscous liquids or liquids containing solid particles, such as sewage and sludge treatment. These pumps provide a constant flow rate and are suitable for high viscosity and high solids content media.

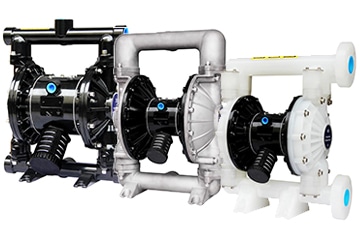

Diaphragm pumps: Diaphragm pumps for handling applications containing corrosive chemicals or where precise flow control is required. Suitable where high accuracy and chemical resistance are required.

Submersible pumps: Mainly used for handling groundwater or deep well pumping, suitable for applications where air needs to be prevented from entering the system.

Piston pumps: Suitable for high-pressure, low-flow applications such as chemical dosing and pressurized water supply systems.

Summary

Flow unit conversion is an essential skill for water treatment and pumping equipment professionals. By understanding and applying the conversion from m³/min to cfm, you can better design, manage, and optimize your water treatment system to improve system efficiency.

AOBL Pumps offers a wide variety of pump products to meet the needs of different customers. The pumps are available in a full range of sizes, capacities and materials for a variety of application scenarios. With a range of industrial products such as chemical pumps, EODD pumps, filter press feed pumps, and pulsation dampers, contact us to develop a program for you.