NPSH In Centrifugal Pump

Centrifugal pumps are a common power pump used to pump liquids from a low-pressure area to a high-pressure area. At the suction end of the pump, the liquid must overcome factors such as a drop in the liquid surface, an increase in the liquid’s temperature, and the gas’s solubility to ensure that the pump draws in the liquid properly without cavitation. Therefore, the calculation and management of NPSH are very important for the selection and operation of centrifugal pumps.

What is npsh in centrifugal pumps?

NPSH of centrifugal pump is the abbreviation of Net Positive Suction Head, directly translated as Net Positive Suction Head, which we are used to call cavitation margin. It refers to the impeller inlet (relative to the reference plane) liquid having more than the energy of the saturated vapor pressure at that temperature, which is determined by the pump installation conditions, expressed in the form of head, in meters.

Centrifugal pumps are the most common type of process pump. They are used to transport a variety of fluids, including water, chemicals and slurries. Centrifugal pumps work by spinning an impeller, which creates centrifugal force that forces fluid out of the pump. NPSH is a critical parameter in centrifugal pumps, which represents the ability of the pump to draw in liquid under specific conditions. Cavitation in centrifugal pumps is the phenomenon of gas cavitation that occurs in the pump during pump operation.

NPSH has two main parameters

- NPSHA (Net Positive Suction Head Available): Indicates the Net Positive Suction Head (NPSH) provided by the liquid supply system, i.e., the Net Positive Suction Head (NPSH) of the liquid provided by the system. It includes factors such as atmospheric pressure, liquid level height, and vapor pressure.

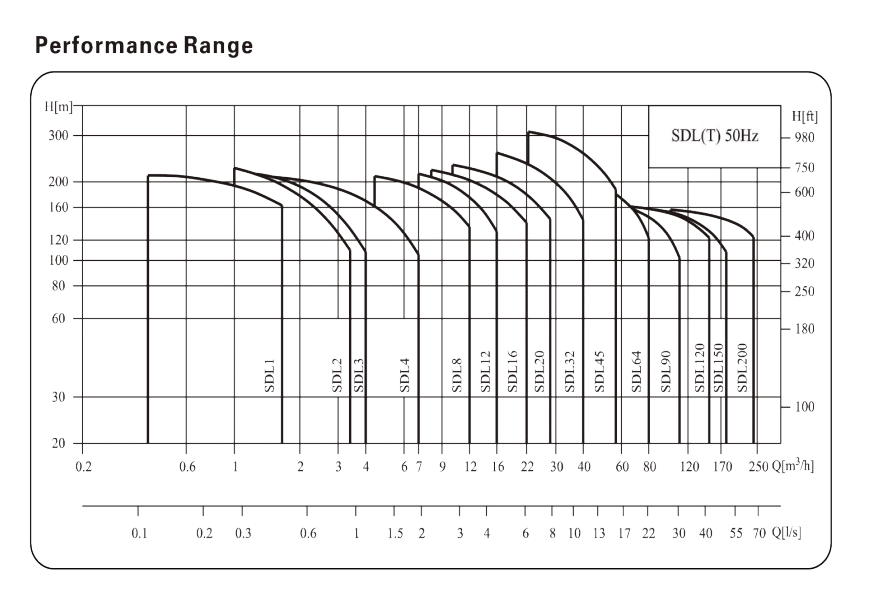

- NPSHR (Net Positive Suction Head Requirement, Required Vapor Residual): Indicates the minimum NPSH value required for a specific centrifugal pump on its performance curve to ensure proper pump operation. The minimum pressure is required at the pump suction inlet to prevent pump cavitation.

NPSH and cavitation risk at maximum flow rate

In pump systems, pumps typically experience different operating conditions, including different flow requirements. NPSH at maximum flow refers to the value of NPSH required when the pump is operating at its maximum allowable flow. Under maximum flow operation, the risk of cavitation is more pronounced because the pump requires more NPSH to prevent cavitation. To manage this risk, it is necessary to ensure that the system provides sufficient NPSHA to meet the NPSHR of the pump at maximum flow. This may require measures such as increasing the liquid level, optimizing the piping design, controlling the liquid temperature, etc.

NPSH key link in centrifugal pump systems

NPSH is closely related to centrifugal pumps and pump accessories associated with centrifugal pumps.

Centrifugal pumps: NPSH is a key parameter used to evaluate the performance and operation of centrifugal pumps. It measures the Net Positive Suction Head (NPSH) that a liquid supply system can provide to ensure that the pump can draw liquid properly without cavitation. Centrifugal pump selection, design, and performance evaluation need to consider NPSH. Vertical chemical pumps are suitable for most applications and are used to lift, circulate, and transport corrosive liquids (acidic, alkaline), clean industrial liquids, liquids containing various impurities, and waste liquids.

Suction lines: The suction lines and fittings of centrifugal pumps have a significant impact on NPSH. Suction lines must be designed to ensure a smooth supply of liquid to the pump to maintain adequate NPSHA. Any resistance, holes, or improper design of the suction line can lead to inadequate NPSHA, which can cause cavitation problems. Excessively long suction lines, scaling of the suction line, and suction lines equipped with fittings and devices (control valves, spring-loaded check valves, heat exchangers, filters, etc.) can cause the NPSHa curve to drop dramatically. A pump with this profile is a high-maintenance pump.

Valves and accessories: In centrifugal pump systems, various valves and accessories may also affect NPSH. Improper valve settings, leaks, or incorrect installation may affect NPSHA. Reducing friction losses (Hf) in the suction pipe is the most creative way to extend the NPSHa curve and reduce the downward slope. Many piping systems are designed with butterfly valves on the suction side of the pump. Butterfly valves can consume a lot of energy and render the pump inoperable.

Pump NPSHR: Each centrifugal pump model and manufacturer has a specific NPSHR (Net Positive Suction Head Requirement), which indicates the minimum NPSH value required for a particular pump on its performance curve. This parameter is very important in the pump selection process because it tells you the level of NPSH required by the selected pump. You must ensure that the liquid supply system provides sufficient NPSHA to meet the NPSHR of the selected pump.

There is a close connection between NPSH and centrifugal pumps and their associated piping, valves, and accessories. Proper management of the NPSH is a key factor in ensuring that centrifugal pumps can operate properly and avoid cavitation and other performance problems.

The difference between diaphragm pump and centrifugal pump

| Features | Diaphragm pumps | Centrifugal pumps |

| Working principle | Positive displacement pump | Horizontal pump |

| The meaning of NPSH | Not applicable | Key performance parameters |

| Liquid supply system impact | Not applicable | NPSHA must be higher than NPSHR to avoid cavitation |

| Cavitation risk | Not applicable | Cavitation can occur and affect pump performance |

| Applicable fields | Chemical industry, food processing, pharmaceutical manufacturing, viscous liquids, etc. | Sewage treatment, water supply, cooling system, etc. |

| Operational requirements | Relatively little attention is paid to the fluid supply and NPSH | Adequate NPSHA must be ensured to meet the NPSHR of the pump |

| Corrosion resistance | Good corrosion resistance | Limited by liquid properties |

| Material selection | Made of special corrosion-resistant materials | Based on liquid properties |

| Flow control | Can accurately control flow within a wide range | Limited by pump speed and design |

This comparison table highlights the key differences between diaphragm and centrifugal pumps, particularly in terms of the significance of NPSH, liquid supply system effects and cavitation risk. Diaphragm pumps are typically used in applications requiring high precision and corrosion resistance, while centrifugal pumps are used in applications involving large flow rates where NPSH is a critical parameter to ensure proper pump operation.

NPSH calculation for centrifugal pumps

The Net Positive Suction Pressure (NPSH) calculation for centrifugal pumps involves two main parameters: NPSH Available (NPSHA) and NPSH Required (NPSHR).

Calculate NPSHA:

NPSHA indicates the net positive suction pressure available from the liquid supply system and must be greater than or at least equal to the NPSHR of the pump to ensure that the pump will not cavitate. NPSHA is calculated as follows:

NPSHA = Pa – Pv – hL – hVPa = Absolute Pressure (Pa): The absolute pressure on the surface of a liquid, usually expressed in pascals (Pa). The absolute pressure can be calculated using atmospheric pressure and the level height of the liquid.

Pv = Vapor pressure (Pv): The vapor pressure of a liquid, usually expressed in Pascals (Pa). This usually depends on the type and temperature of the liquid.

HL = Height of liquid at level (hL): The height of the liquid at level, usually expressed in meters (m).

HV = Velocity head of the liquid below the liquid level (hV): This can usually be ignored but may need to be taken into account at high flow rates.

How to avoid cavitation in centrifugal pumps?

- Provide sufficient NPSH: Ensure that the liquid supply system provides sufficient NPSHA to meet the pump’s NPSHR. The NPSHA must be greater than or at least equal to the NPSHR to ensure that the pump will operate properly without cavitation.

- Maintain liquid level to prevent foam formation: Ensure that the liquid level in the liquid source is high enough to provide the required NPSHA. A drop in level may result in insufficient NPSHA. Avoid air bubbles or foam formation in the fluid. Fine air bubbles can increase the risk of cavitation. Reduce bubble formation by maintaining the fluid temperature and agitating the fluid.

- Control fluid temperature: Ensure that the fluid temperature is within the proper range to maintain proper gas solubility. If the liquid temperature increases, gas solubility decreases and cavitation is easily caused.

- Use proper suction line design: Select and design the proper size and type of suction piping, valves and accessories to minimize the risk of cavitation. Avoid drastic piping changes and resistance to reduce the velocity of the liquid and its tendency to cavitate.

- Adjustment of pump operating parameters: Where possible, adjust pump operating parameters, such as lowering the pump flow rate or raising the liquid level, to increase the NPSHA.

- Periodic Maintenance and Inspection: Inspect and maintain the pump regularly to ensure proper operation of all parts and to avoid leaks and damage.

Summary

NPSH is a critical factor in ensuring stable operation of fluid handling systems in a variety of applications. By having a deep understanding of NPSH and taking appropriate measures, we can ensure that centrifugal pumps can reliably meet our needs under different operating conditions.

AOBL provides fluid handling equipment to customers and industries around the world, including electric diaphragm pumps, sanitary pumps, FDA pumps, filter press pumps, progressive cavity pump, chemical pumps, magnetic pumps and other equipment. Welcome to contact us.