Pump Skid

In modern industry, efficient and reliable fluid transfer is key to ensuring that production processes run smoothly. The pump skid is an efficient solution designed to achieve this. Whether in the oil and gas, water treatment, food and beverage, or chemical industries, pump skids play a vital role. In this article, we will take a closer look at the fundamentals of pump skid systems, their key features, and their applications in various industries.

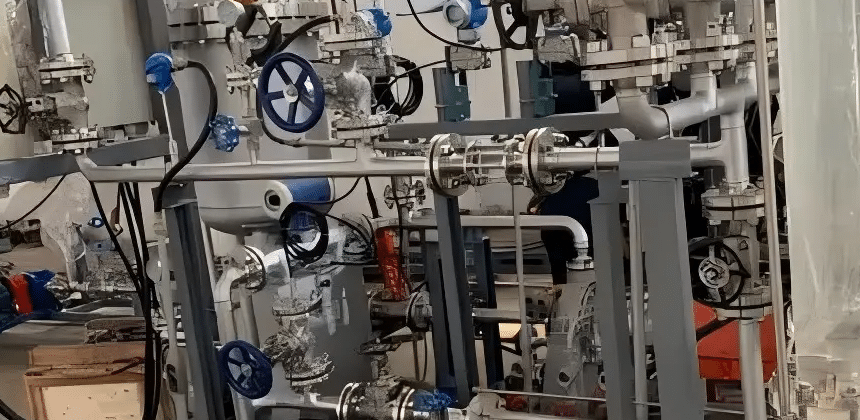

What is a pump skid?

Pump skid mounted system It is a pre-assembled pump system that usually includes key components such as pumps, piping, valves, control systems, etc., mounted on a sturdy frame or base. This type of system is compact in design, easy to transport, install and maintain, and is widely used in oil and gas, water treatment, chemical and other industries. Its main advantages include saving space, reducing on-site installation time and improving the overall reliability of the system.

Appliance

- Oil & Gas

- Water Treatment

- Chemical Industry

- Food & Beverage

- Pharmaceuticals

Pump Skid Assembly

The key components of a pump skid system include the following, each of which plays a vital role in the overall function of the system:

1. Types of pumps

Centrifugal pumps: Centrifugal pumps push liquids from the center to the outside by centrifugal force and are suitable for high flow, low viscosity liquid transfer such as water and light oil. This type of pump is widely used in various industries for its high efficiency and low maintenance.

Positive displacement pumps: Positive displacement pumps discharge liquid gradually through a fixed volume chamber and are suitable for high viscosity, high pressure conditions of fluid transportation, such as chemicals and food slurries. They are widely used for their precise flow control capability.

2. Piping and Valves

Piping: connects the pump inlet and outlet to ensure smooth fluid flow. The material and size of the piping are selected based on the characteristics of the fluid being handled and the operating conditions to ensure the durability and efficiency of the system.

Valves: control the direction, pressure and velocity of fluid flow. Common types of valves include globe valves, check valves and regulating valves, which play different roles in different application scenarios to ensure safe and controllable operation of the system.

3. Control and Monitoring System

Control system: through automated controllers and sensors, monitoring and regulating pump operation parameters, such as flow, pressure, and temperature. Modern pump skid-mounted systems are usually equipped with PLC (Programmable Logic Controller) or DCS (Distributed Control System) to realize automated operation and remote monitoring to ensure efficient system operation.

Monitoring system: monitors the system’s performance in real time and detects possible malfunctions or anomalies. This includes pressure gauges, flow meters, temperature sensors, etc., to ensure a quick response under any circumstances and to safeguard the stability of the system.

4. Base and Frame

Base: Provides support for the entire system and is usually made of steel or aluminum alloy for corrosion resistance and high strength. The base is designed to ensure the smoothness of the system and to minimize the effect of vibration on system performance.

Frame: Holds the components in place and ensures that they are tightly connected and work together. The frame design takes into account the ease of maintenance and transportation of the system and can withstand the physical stresses and shocks of the operating environment.

Why choose a pump skid?

Time and cost savings: Pre-assembled systems reduce on-site installation and commissioning time, lowering labor and material costs.

Modularity and customization: The system can be customized according to specific application needs, offering high flexibility.

High reliability and safety: All components are rigorously tested in the factory to ensure reliability and compliance with industry standards.

Ease of maintenance: The centralized design makes operation and maintenance easier, reducing downtime.

Space efficiency: The compact design saves space, making it suitable for various industrial environments.

Advantages of Pump Skid

- Cost savings

- Modularity and customization

- High reliability

- Easy maintenance

- Small footprint

Summary

The pump skid system, known for its efficiency, reliability, and customization features, has become an indispensable core component across various industries. Whether you are looking for solutions to improve production efficiency or need to optimize existing systems, a pump skid system can meet your needs. By thoroughly understanding and correctly selecting the appropriate pump skid system, you can ensure smooth production processes while significantly enhancing overall efficiency.

As a leading pump manufacturer, AOBL specializes in delivering high-quality, reliable pump systems for various industrial applications. We offer a range of pumps, including diaphragm pumps, EODD diaphragm pumps, sanitary diaphragm pumps, filter press feed pumps, and screw pumps, as well as a wide selection of pump accessories. If you’re interested, feel free to visit our website and contact our professional team for a customized solution tailored to your needs.