Shear Rate VS Viscosity

What is shear rate?

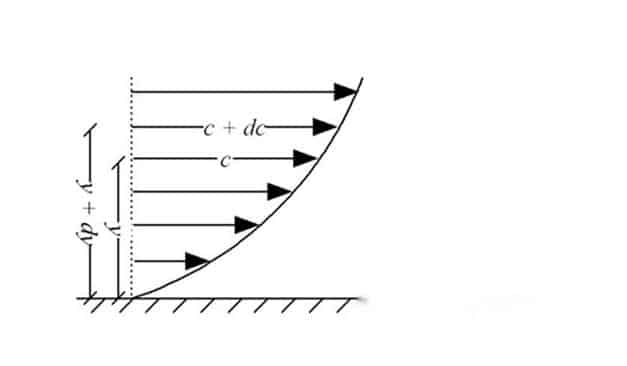

Shear rate is a physical quantity that describes the degree of relative motion within a fluid. It represents the rate of relative motion between different layers within a fluid, i.e., the degree of relative slip between neighboring layers per unit time. In a fluid, there is relative motion between different layers due to the presence of viscosity, and the shear rate is the parameter that describes the extent of this relative motion.

Measurement Of Shear Rate

Shear rate measurements depend on the specific experimental or application scenario, and the following are some common measurements:

- Plate shear rheometer: This is a common laboratory device that measures the shear stress applied to a fluid and the resulting shear rate by placing the fluid between two rotating plates. The shear rate can be adjusted by varying the rotational speed or gap.

- Cylinder shear rheometer: Similar to the plate rheometer, but using a rotating cylinder. This design is more suitable for some special types of fluids.

- Couette cell: This is a device used to measure shear rate where the fluid to be tested is sandwiched between two concentric cylinders. By rotating the outer cylinder, a shearing force is generated and the shear rate is measured.

- Laser Doppler velocimetry (LDV): This is a non-contact, highly accurate method of calculating shear rate by measuring the frequency shift of scattered light to obtain the velocity of particles in a fluid.

- Digital image correlation (DIC): A high-speed camera is used to record the movement of particles or markers in the fluid, and the shear rate is calculated by image processing techniques.

- Fluid simulation software: Using Computational Fluid Dynamics (CFD) software, the shear rate distribution at different locations in the fluid can be simulated and predicted.

Difference Between Shear Rate And Shear Rate

Shear Rate and Shear Strain Rate are two related but different concepts that are often used in fluid mechanics and materials science.

Shear Rate

Shear rate is the relative speed of motion between a layer and an adjacent layer of a fluid or substance per unit of time. In fluids, it is usually expressed as the velocity gradient between two neighboring liquid layers.

Shear Strain Rate (SSR)

Definition: Shear rate is the degree of deformation of a substance or a layer in a fluid per unit of time. In strain theory, shear rate is relative to shear deformation.

Shear rate emphasizes the relative speed of motion between two adjacent layers and is often used to characterize the motion of a fluid. Shear rate emphasizes the degree of deformation and is usually used in cases such as elastic deformation of materials.

In fluid dynamics, these two concepts are often used interchangeably, depending on the problem being studied and the area of application.

Variation Of Shear Rate In Different Fluids

In practice, for different types of fluids, it is important to understand the shear rate variations for the control and optimization of industrial processes. These properties directly affect processes such as flow, pumping, and mixing of fluids in pipelines.

| Type | Characteristic | Shear Rate Change |

| Newtonian fluids | Constant viscosity | Increased shear rate does not affect viscosity |

| Shear thinning fluids | Viscosity decreases with increasing shear rate | Higher shear rates exhibit lower viscosity |

| Shear thickening fluids | With the increase of shear rate, the viscosity increases gradually | Exhibits higher viscosity at higher shear rates |

| Non-Newtonian fluids | The viscosity change rule is complex, and not in line with the law of Newtonian fluids | Changes in shear rate have a significant effect on viscosity, possibly thinning or thickening |

| Plastic fluids | With a shear threshold, low shear rate such as rigid solids | Above shear threshold exhibits viscoplastic transition |

What is viscosity?

Viscosity is a property that describes the resistance of a fluid to flow, i.e. the internal resistance of a fluid. It reflects the adhesive forces between fluid molecules and the cohesive forces within fluid molecules. The magnitude of the viscosity determines the degree of deformation of the fluid when shear is applied, i.e., how sensitive the fluid is to shear.

Dynamic Viscosity

Usually expressed by the Greek letter μ (mu) in Pa.s. or Nm. Pa-s or N-s/m². Seconds per square meter (N-s/m²). Dynamic viscosity describes the degree of resistance of a fluid to shear.

Kinematic Viscosity

Kinematic viscosity is the dynamic viscosity divided by the density of the fluid, usually expressed by the Greek letter ν (nu), in square meters/second (m² / s). Kinematic viscosity describes the degree of cohesion of a fluid, i.e. the interaction between fluid molecules.

Relative Viscosity

Relative viscosity is an important parameter when measuring dissolved polymers. The mass of a polymer is closely related to its molar mass. Most polymers show a clear relationship between molar mass and viscosity. Therefore, to determine the molar mass, the viscosity can be measured. Typically, the viscosity of a polymer solution increases as the molar mass increases. Most polymer solutions are shear-related (i.e., non-Newtonian).

Measurement of Viscosity

- Rotational viscometer: Uses a rotating cylinder or disk to create a shear force in a fluid, measuring the torque required as well as the rotational velocity of the fluid. According to Newton’s law of viscosity, the shear stress is directly proportional to the shear rate.

- Oscillatory viscometer: Utilizes a vibrating filament or cylinder passing through a fluid and determines the viscosity of the fluid by measuring the damping of the vibrations.

- Titration viscometer: Measures the rate of flow of a fluid through a pipe or orifice. The viscosity is calculated by measuring the time it takes for the fluid to pass through a standard orifice.

- Cone-plate viscometer: Places the fluid between rotating cones or plates and measures the torque required and the speed at which the fluid rotates.

- Vortex flow method: Viscosity is determined by measuring the speed of rotation of a fluid in a pipe, utilizing the shear forces generated by the vortex.

- Compressed gas method: A measurement method applicable to gases where the viscosity is calculated by compressing the gas and measuring its flow.

- Resonant tube method: Measures the viscosity of a fluid by utilizing the resonant frequency change of a resonant tube.

Viscosity Changes In Different Fluids

| Fluid Type | Viscosity Characteristics |

| Water | Low viscosity, easy to flow |

| Syrup and Honey | Highly concentrated sugar solutions, higher viscosity |

| Oil | Different types of oil have different viscosities, relatively high |

| Polymer solution | Liquid containing a polymer, may have high viscosity |

| Gases | Usually very low viscosity and relatively free-flowing |

| Liquid metals | relatively low viscosity at high temperatures |

Effect of temperature, pressure and other factors on viscosity

Temperature effects

In general, the viscosity of a fluid decreases as the temperature increases. This is because higher temperatures increase the energy of movement of molecules, making it easier for them to slide against each other and reducing viscous resistance.

For liquids, viscosity decreases exponentially with increasing temperature. But for gases, an increase in temperature causes the gas molecules to move faster, increasing their viscosity.

Pressure effect

In liquids, the effect of pressure on viscosity is usually small. Within a certain range, the viscosity of a liquid is insensitive to changes in pressure.

In the case of gases, an increase in pressure may lead to an increase in collisions between gas molecules, which increases the viscosity of the gas and makes it exhibit greater viscosity.

Relationship Between Shear Rate And Viscosity

Newtonian fluids

- In Newtonian fluids, shear rate and viscosity are directly proportional. This means that the viscosity of a Newtonian fluid remains constant at any shear rate, in accordance with Newton’s law of viscosity.

- Newtonian fluids are characterized by the fact that their viscosity is linear with respect to the shear rate, i.e., the value of viscosity does not vary with the shear rate.

Non-Newtonian fluids

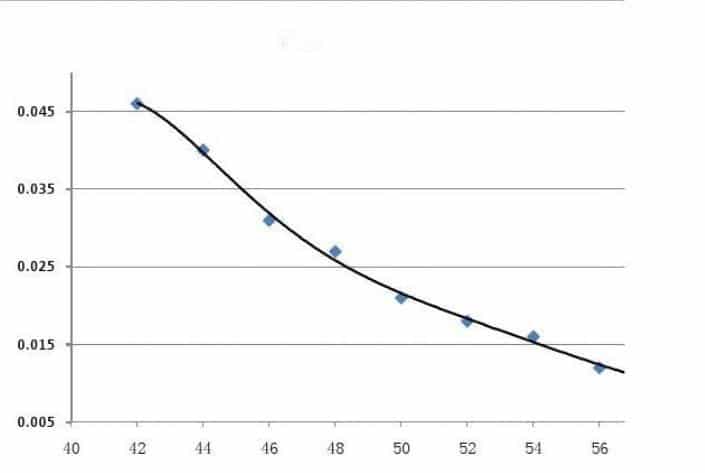

- In non-Newtonian fluids, the relationship between shear rate and viscosity is usually non-linear. This means that the viscosity of non-Newtonian fluids varies with the shear rate.

- There are many types of fluids classified as non-Newtonian, including plastic, pseudoplastic, and malleable fluids. In these fluids, the viscosity may increase with increasing shear rate (pseudoplastic fluids), remain constant (plastic fluids), or decrease with increasing shear rate (plastic fluids).

The relationship between shear rate and viscosity is an important aspect of fluid properties and is important for understanding fluid behavior, industrial applications, and rheological studies. This relationship is also an important indicator for distinguishing the behavior of different types of fluids.

Influence of Different Liquid Viscosities On Pump Selection

Viscosity is an important parameter when selecting a pump as it affects pump efficiency, flow rate and head. It is necessary to choose the right type of pump according to the viscosity characteristics of the liquid to ensure good performance and long-term stable operation.

Low (water sample liquid)

- Applicable pump types: Centrifugal pumps, screw pumps, reciprocating pumps.

- Low viscosity liquids require pumps with high flow rates and low heads.

Medium viscosity liquids

- Applicable pump types: Centrifugal pumps, gear pumps, piston pumps.

- These pump types are suitable for medium-viscosity liquids, providing appropriate flow rates and heads.

Highly viscous liquids (concentrated oils, syrups, etc.)

- Applicable pump types: Progressive cavity pump, piston pumps.

- Highly viscous liquids require pumps with higher torque and lower speeds to push the liquid.

Non-Newtonian fluids

- Applicable pump types: Peristaltic pumps, and piston pumps.

- Pumps for non-Newtonian fluids can handle variable viscosity and particle content.

Chemical liquids (corrosive, erosive, etc.)

- Applicable pump types: Diaphragm pumps, and peristaltic pumps.

- These pump types are usually made of materials that resist corrosion and are easy to clean.

Shear Rate Versus Different Pump Types

Shear rate is the relative displacement speed of molecules inside a liquid, which is closely related to the viscosity and flow behavior of the liquid. The effect of different pump types on shear rate depends on their operating principle and fluid transfer mechanism.

- Centrifugal Pump:

- Shear rate effect: The working principle of a centrifugal pump causes the liquid to rotate at high speed between the impeller and the pump casing, resulting in a relatively low shear rate.

- Applicable liquids: Suitable for low to medium viscosity liquids, there may be limitations for high viscosity or particle-containing liquids.

- Screw Pump:

- Shear rate effect: The screw pump pushes the liquid to the outlet through the rotation of the spiral screw, resulting in a relatively high shear rate.

- Applicable liquids: Suitable for medium to high viscosity liquids, but may not be suitable for low viscosity liquids.

- Reciprocating Pump:

- Shear rate effect: Reciprocating pumps produce higher shear rates through reciprocating motion and are suitable for applications requiring higher shear forces.

- Applicable liquids: Suitable for liquids with high viscosity, easy solidification or requiring high shear.

- Peristaltic Pump:

- Shear rate effect: Peristaltic pumps push fluid by compressing the hose, producing a lower shear rate.

- Applicable liquids: Suitable for shear-sensitive liquids, especially biological products and high-viscosity liquids.

- Diaphragm Pump:

- Shear rate effect: Diaphragm pumps use a diaphragm to push a liquid, producing a relatively low shear rate.

- Applicable liquids: Suitable for shear-sensitive liquids and often used to handle corrosive or volatile chemicals.

The choice of different pump types depends on factors such as the fluid’s viscosity, chemical properties, particle content, and sensitivity to shear. In practical applications, the liquid characteristics need to be carefully evaluated to determine the most suitable pump type.

Shear Rate Challenges Diaphragm Pump Performance

Diaphragm pumps may face shear rate challenges when handling different fluids, which has an impact on their performance and application. The following are some of the challenges of shear rate on diaphragm pump performance:

- Effects of Shear on Viscous Fluids: When handling highly viscous fluids, the shear rate may result in relative motion within the fluid, increasing the suction and discharge resistance of the pump. This may result in a decrease in pump efficiency and require more power to propel the fluid.

- Shear-induced wear: At higher shear rates, the sealing elements and diaphragms inside the diaphragm pump may be subjected to greater wear. This can shorten pump life and increase maintenance costs.

- Shear Heat and Temperature Rise: High shear rates may cause shear heat in the fluid, resulting in a temperature rise. For some sensitive fluids, especially those used in chemical and biological processing, shear heat may affect stability and performance.

- Effects of shear on granular materials: If solid particles are present in the liquid, the shear rate may cause the particles to break up or deform, affecting the proper operation of the pump. When handling granular materials, the suitability of the shear rate for the pump needs to be considered.

To overcome these challenges, diaphragm pump design and sizing needs to take into account the characteristics of the fluid, including viscosity, particle content, and sensitivity to shear. In addition, using diaphragm pumps with low-shear designs or diaphragms made of special materials can reduce the adverse effects of shear on pump performance.

Summary

In practical fluid dynamics and pump selection, understanding and considering the relationship between shear rate and density is critical to properly understanding fluid behavior and optimizing system performance.

AOBL as a specialist in fluid pumps, we offer magnetic drive pump, filter press feed pump, chemical pump, diaphragm pump parts & accessories, please contact us for your solution.