Advantages And Disadvantages Of Centrifugal Pump

Centrifugal pump is a widely used mechanical device, mainly used for transferring liquids or increasing the pressure of liquids. It is widely used in various industries such as water supply systems, agricultural irrigation, chemical processes, fire control, heating and ventilation, etc.

Recognizing centrifugal pumps

What is centrifugal pump?

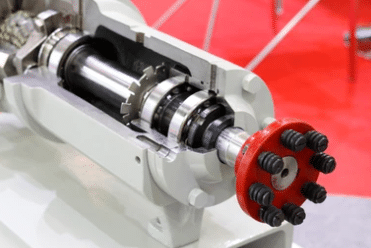

A centrifugal pump is a common type of fluid transfer device that uses a rotating impeller (a rotating disk with multiple vanes) to convert mechanical energy into kinetic and pressure energy in a liquid. This action causes the fluid to flow and can provide a certain amount of lift or pressure. Centrifugal pumps consist of an impeller, pump casing, inlet and outlet, seals, bearings, couplings, drive unit, and pump pressure head.

Working principle of centrifugal pumps

Force is applied to the liquid by means of a rotating impeller (a spinning disk with multiple vanes mounted around its perimeter). When a motor drives the pump’s impeller to rotate, the rotational speed of the impeller causes the liquid to create a rotational motion, which creates centrifugal force. This centrifugal force pushes the liquid against the pump casing, a process that increases both the velocity and pressure of the liquid. The liquid then flows out through the outlet of the pump. While the liquid is being thrown out by the impeller, the pressure in the center of the impeller decreases, creating a low-pressure zone that allows new liquid from the pump inlet to enter and be thrown out again by the impeller, and so on, creating a continuous liquid transfer process.

Centrifugal pump applications

- Water supply system

- Agricultural irrigation

- Chemical processes

- Fire control

- Heating and ventilation

- Food and beverage industry

Relationship between process pumps and centrifugal pumps

Process pumps and centrifugal pumps are related primarily in that they are both types of pumping equipment, but they differ in their principles of operation and areas of application. Process pumps are pumps that are specifically designed for the transfer of liquids in a process and are suitable for a variety of different process applications, including chemical processing, petroleum, food and beverage production, and more. There may be a number of different types of process pumps, including centrifugal pumps, screw pumps, double diaphragm pumps, and so on, so a centrifugal pump can actually be a process pump.

Different types of centrifugal pumps

- End-suction centrifugal pumps: Also known as single-suction centrifugal pumps, are designed so that liquid enters the pump from only one direction. These pumps are usually used in water supply and hot water systems.

- Double suction centrifugal pumps: In contrast to end suction centrifugal pumps, double suction centrifugal pumps are designed so that liquid is introduced from two directions. This type of pump is widely used in petroleum, chemical and electric power fields.

- Multi-stage centrifugal pumps: These pumps have multiple impeller sets, each with its own level. Each stage increases the pressure of the pump, making the multistage centrifugal pump capable of providing higher pressure. This type of pump is mainly used in high pressure washing system, boiler feed water system.

- Self-priming centrifugal pumps: This type of pump is self priming and does not require filling of the pump body before starting. It is widely used in irrigation, utilities, sewage treatment and other fields.

- Vertical centrifugal pumps: The motor of this pump is located on top of the pump body, the impeller is located below, and is usually completely submerged by the pumping medium. They are widely used in groundwater lifting, chemical processes and so on.

- Submersible centrifugal pumps: These pumps are designed to operate fully submerged in the pumping medium. They are commonly used for deep well water lifting, groundwater harvesting, drainage processes, etc.

Advantages and disadvantages of centrifugal pumps

| Advantages | Disadvantages |

| High efficiency | Sensitive to air and vapors |

| Simple maintenance | Higher starting pressure |

| Stable operation | Cannot convey highly viscous liquids |

| Wide range of applications | Requires regular maintenance |

Difference between centrifugal and diaphragm pumps

| Features | Centrifugal Pumps | Diaphragm Pumps |

| Working Principle | Centrifugal force moves the liquid, which in turn raises the pressure | The repeated movement of the diaphragm makes the liquid flow inside the pump. |

| Fluid Type | Ideal for clean liquids with small amounts of suspended material | Can handle viscous, corrosive liquids containing large amounts of suspended substances or particles. |

| Stability | Smoother operation, requires maintenance | Stable, durable, dry runnable, easy to maintain |

| Energy Consumption | Generally higher and capable of handling high flows | Slightly less energy efficient, suitable for small to medium flows |

| Flow Rate Adjustment | Flow rate can be changed by adjusting the speed | Flow rate can be adjusted by changing air pressure |

| Lift | Generally higher | Generally lower |

What is diaphragm pump?

Diaphragm pump is a special volume pump with a wide range of applications. It uses a soft and flexible diaphragm (made of rubber, plastic or metal) to reciprocate between the two chambers of the pump, accomplishing the transfer of liquids or gases through suction and discharge action. Diaphragm pumps are also widely used in different industries.

How to choose diaphragm Or centrifugal pumps?

- Fluid properties: This includes the viscosity of the fluid, whether it contains solid particles, and whether it is corrosive or flammable. For example, fluids that contain a lot of solid particles or have a high viscosity may be more suitable for pneumatic pumps. Clean, low-viscosity fluids are more suitable for centrifugal pumps.

- Flow and head requirements: Centrifugal pumps are typically used for high flow and medium head applications, whereas pneumatic pumps can provide higher pressures and are more suited to applications requiring higher heads.

- Energy efficiency: Typically, centrifugal pumps are more energy efficient than pneumatic pumps, so if there is a high demand for energy efficiency, a centrifugal pump may be preferred.

- Maintenance and longevity: Centrifugal pumps have a more complex structure and require regular maintenance and replacement of parts. While the structure of the air operated double diaphragm pump is simple, less maintenance needs.

- Environment: If the working environment may have a risk of explosion, it is safer to use pneumatic pumps as they do not produce sparks. In addition, if the environment of the power supply is unstable or can not provide electricity, pneumatic pumps are also a better choice, because they can be driven by compressed air or gas.

How to use centrifugal pumps?

- Installation: Install the centrifugal pump in the correct position, make sure it is stable and has no loose parts, and make sure that the inlet and outlet of the pump are correctly connected to the corresponding pipelines.

- Filling with liquid: Before starting the pump, it is necessary to ensure that the pump is filled with liquid, that is, to “fill the pump”. Centrifugal pumps should not be operated without liquid, otherwise the internal structure of the pump will be damaged.

- Start-up: Ensure that all connections are securely made and that the power is turned on. The centrifugal pump starts working, transferring liquid from one place to another.

- Operation and monitoring: During pump operation, you need to regularly check the pump’s operating conditions, such as whether the liquid flow and pressure are normal, whether the pump has abnormal vibration or noise, and whether the motor is overheated.

- Shutdown: When shutting down the pump, the outlet valve of the pump should be closed first, and then the power supply should be shut down.

- Maintenance: Perform pump maintenance on a regular basis, including cleaning the inside of the pump and replacing worn parts.

How to maintain centrifugal pumps?

- Regular Cleaning

- Regular cleaning

- Regular replacement of wear parts

- Keep lubricated

- Protect against freezing and heat

summary

Centrifugal pump is a widely used equipment for transferring liquids in industry and households. It is simple in construction, easy to manufacture and maintain, smooth in operation, low in noise and vibration, and capable of delivering high head and high efficiency under the right conditions. AOBL as a specialist in fluid pumping, we offer sanitary diaphragm pumps, electric diaphragm pumps as well as pump accessories, please contact the specialized technical team for your solution.