What Are Diaphragm Pumps Used For?

What is a diaphragm pump?

Diaphragm pump, also known as a double diaphragm pump, is a positive displacement reciprocating pump that has an internal set of diaphragms that work simultaneously to generate pressure to push fluid through the pump.

Diaphragm pumps are indispensable tools in numerous industries due to their versatility, reliability, and ability to handle a wide range of fluids. These pumps find applications in various sectors, contributing to efficient fluid transfer and processing.

Uses for Diaphragm Pump

Diaphragm Pumps in Water Treatment

Diaphragm pumps are employed in waste water systems for pumping and transferring various types of waste, including sewage, sludge, and effluent. They can handle solids and semi-solids, making them suitable for such applications.

Diaphragm Pumps in the Chemical Industry

Diaphragm pumps are extensively used in the chemical industry for handling and transferring chemicals, acids, solvents, and other aggressive substances. Their ability to resist corrosion makes them suitable for such applications.

Diaphragm Pumps in the Pharmaceutical Industry

Accurate fluid transfer is important in pharmaceutical production. Diaphragm pumps contribute to the safe and precise transfer of solvents, acids, bases and other pharmaceutical ingredients. They are used in all stages of pharmaceutical production and formulation.

Food and beverage industry

They are typically used to pump liquids such as juices, sauces, dairy products and liquid ingredients, while maintaining hygiene and avoiding contamination.

Mining and construction

Diaphragm pumps are used in mining and construction sites for dewatering excavations, pumping mud and slurry, and pumping abrasive materials such as sludge and silt.

Agriculture and irrigation

Diaphragm pumps are used in agriculture for tasks such as crop spraying, irrigation, and transporting water and fertilizers. They are often selected for their self-priming ability and their ability to convey dirt and small solids.

Automotive and Manufacturing

Diaphragm pumps are used in the automotive and manufacturing industries for fluid transfer, lubrication systems, coolant circulation, and other processes requiring precise and controlled fluid delivery.

Environmental monitoring

Diaphragm pumps can be used in environmental monitoring applications to collect and transport samples to test facilities and then use air samplers and water quality analyzers.

Medical and laboratory applications

Diaphragm pumps are used in medical equipment, laboratories and research facilities for fluid handling, vacuum generation and filtration processes.

Fluid transfer

Diaphragm pumps are typically used to transfer liquids and gases from one location to another. They can transfer a variety of fluids, including corrosive, abrasive, viscous, and volatile.

How diaphragm pumps work?

Pneumatic diaphragm pumps use compressed air or gas to flex a diaphragm, to create suction and discharge pressure. When air is applied to one side of the diaphragm, it moves away, and draws fluid into the pump chamber through an inlet valve. When air is directed to the other side of the diaphragm, it flexes in the opposite direction, and forces the fluid out through an outlet valve.

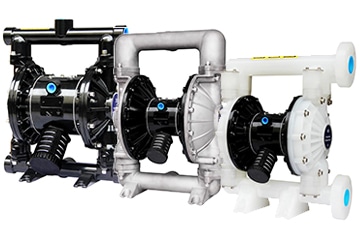

Types of Diaphragm Pumps

AODD pumps utilize compressed air to drive two diaphragms that move alternately to draw in and discharge liquid. Since there is no motor drive, it is particularly suitable for explosion-proof and hazardous chemical handling applications.

Main Features

- No need for electricity, suitable for explosion-proof environment

- High viscosity, corrosive and particulate fluids can be transported.

- Dry running without damaging the pump body, suitable for volatile liquids transportation

- Simple structure and easy maintenance

The electric diaphragm pump is motor-driven, with a mechanical drive system that alternates the motion of the double diaphragms for consistent fluid delivery. It is less dependent on compressed air than the AODD pump, is more energy efficient, and allows for precise flow control.

- Main FeaturesHigher energy efficiency, reducing energy consumption compared to AODD pumps

- Controlled flow rate for precise adjustment of delivery volume

- Quieter operation for reduced noise

- Leak-free design reduces maintenance costs

A double diaphragm pump consists of two alternating diaphragms to ensure stable fluid transfer. They can be driven by either pneumatic (AODD) or electric (EODD) means and are suitable for a wide range of fluids, including corrosive liquids, highly viscous liquids and liquids containing solid particles.

Main Features

- Stable conveying, reducing the effect of flow pulsation

- Conveying different types of fluids (viscous, corrosive, solid particles)

- Low shear conveying to protect fluid properties

- Simple maintenance and low operating costs

Sanitary diaphragm pumps are made of food-grade stainless steel (e.g., 316L) and aseptic design that meets FDA and EHEDG approvals to ensure the safety and cleanliness of the fluid being pumped.

Main Features

- Conforms to food and pharmaceutical industry standards (FDA, 3A, EHEDG approvals)

- Low shear conveying to prevent damage to food or pharmaceutical ingredients

- CIP/SIP compatible, easy to clean and sanitize

- Suitable for high sanitary standards of fluid transportation

Choosing the right diaphragm pump

Fluid type: Determine if the fluid is abrasive, corrosive, viscous, or contains solid particles. Highly viscous fluids usually require a diaphragm pump with a large port design.

Flow and Pressure: Determine flow rate and discharge pressure based on application requirements. Electric diaphragm pumps provide more precise control and are suitable for stable and consistent fluid handling.

Power supply options: If the power supply is unstable, an air-operated diaphragm pump is recommended. Electric diaphragm pumps are preferred in low noise environments or where energy savings are required.

Maintenance and Cost: Air-operated diaphragm pumps have a lower initial cost but higher maintenance, while electric diaphragm pumps are more energy efficient and have a lower total cost of ownership Graco electric diaphragm pumps can reduce energy consumption by up to 80%.

Summary

Diaphragm pumps are essential in various industries due to their ability to handle a wide range of fluids, from corrosive chemicals to high-viscosity liquids and slurries. Their self-priming, leak-free, and dry-run capabilities make them ideal for chemical processing, water treatment, pharmaceuticals, food and beverage, and oil & gas applications. Choosing the right diaphragm pump ensures optimized performance, reduced maintenance, and long-term cost savings.

In the field of water treatment pumps, AOBL has always been committed to providing our customers with high quality products and excellent service. We understand that choosing a reliable manufacturer is crucial, and AOBL is your trusted partner. We offer a wide range of pumps with pump accessories and welcome you to contact us for customized water treatment solutions!