Pump Coupling

What is a pump coupling?

The pump coupling is located between the motor and the pump shaft. It is used to connect the two shafts and to transmit torque from the motor to the pump. The coupling also helps to absorb misalignment between the two shafts, which can help to prevent damage to the pump and the motor.

In most pumps, the coupling is located at the base of the pump, where the motor is connected to the pump shaft. In some pumps, the coupling may be located elsewhere, such as on the side of the pump. The exact location of the coupling will depend on the design of the pump.

The coupling is a critical component of the pump, and it is important to ensure that it is properly installed and maintained. If the coupling is not installed correctly, it can cause damage to the pump and the motor. It is also important to inspect the coupling regularly for wear and tear, and to replace it as needed.

What kinds of pump couplings?

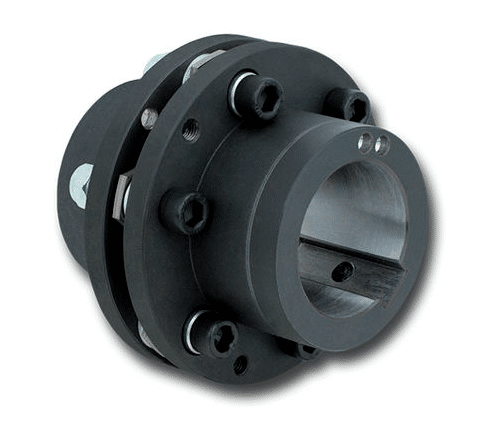

- Rigid couplings: These are the simplest and most common type of pump coupling. They consist of two flanges that are bolted together, with a sleeve or spacer in between to ensure alignment. Rigid couplings are very efficient at transmitting power, but they are not able to accommodate any misalignment between the pump and motor shafts. This can lead to premature bearing wear and seal failure.

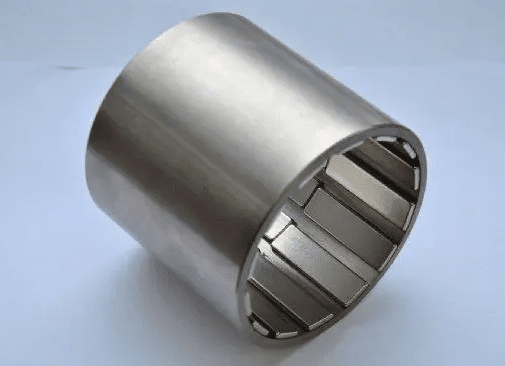

- Flexible couplings: These are designed to accommodate misalignment between the pump and motor shafts. They do this by using a variety of materials, such as rubber, fabric, or metal, that can flex and absorb the misalignment. Flexible couplings are more expensive than rigid couplings, but they can extend the life of the pump and motor by preventing premature bearing wear and seal failure.

- Synchronizing couplings: These are a type of flexible coupling that is used to synchronize the speed of the pump and motor. They do this by using a timing belt or chain that connects the two shafts. Synchronizing couplings are used in applications where the pump and motor must operate at the same speed, such as in centrifugal pumps.

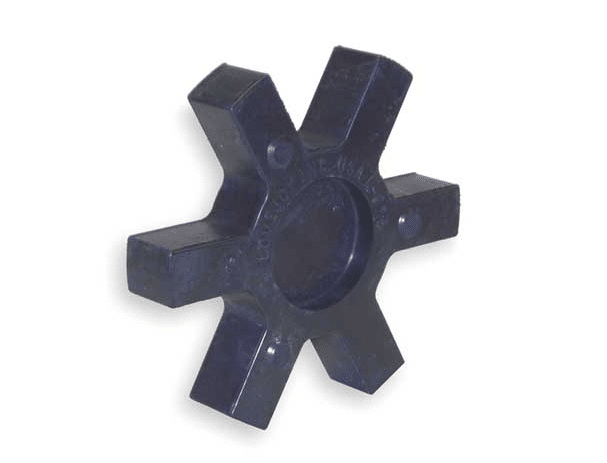

- Jaw couplings: These are a type of rigid coupling that uses a series of teeth to connect the two shafts. Jaw couplings are very strong and can withstand high torque loads. However, they are not as flexible as other types of couplings and cannot accommodate much misalignment.

- Disc couplings: These are a type of flexible coupling that uses a series of discs to connect the two shafts. Disc couplings are very flexible and can accommodate a wide range of misalignment. They are also relatively inexpensive and easy to maintain.

- Elastomeric couplings: These are a type of flexible coupling that uses a rubber or elastomeric material to connect the two shafts. Elastomeric couplings are very flexible and can accommodate a wide range of misalignment. They are also relatively inexpensive and easy to maintain.

- Magnetic couplings: These are a type of coupling that uses magnets to connect the two shafts. Magnetic couplings do not have any moving parts and are therefore very reliable. They are also very efficient at transmitting power. However, magnetic couplings are not as flexible as other types of couplings and cannot accommodate much misalignment.

- Hydraulic couplings: These are a type of coupling that uses a hydraulic fluid to connect the two shafts. Hydraulic couplings are very flexible and can accommodate a wide range of misalignment. They are also very efficient at transmitting power. However, hydraulic couplings are more expensive than other types of couplings and require regular maintenance.

Below is a comparison of pump coupling materials, wearability and costs:

Group1

| Type of Coupling | Material | Wearability | Cost |

| Rigid Couplings | Flanges, sleeve, spacer | Very wear resistant | Inexpensive |

| Jaw Couplings | Metal teeth | Very wear resistant | Inexpensive |

| Magnetic Couplings | Magnets | Very wear resistant | Inexpensive |

| Hydraulic Couplings | Hydraulic fluid | Less wear resistant | More expensive |

Group2

| Type of Coupling | Material | Wearability | Cost |

| Flexible Couplings | Flexible material, such as rubber or fabric | Less wear resistant | More expensive |

| Synchronizing Couplings | Timing belt or chain | Less wear resistant | More expensive |

| Disc Couplings | Series of discs | Less wear resistant | More expensive |

| Elastomeric Couplings | Rubber or elastomeric material | Less wear resistant | More expensive |

What kind of pump is suitable?

- Rigid Couplings: Pumps with low misalignment and high torque loads, such as centrifugal pumps, gear pumps, diaphragm pump and piston pumps. Like AOBL KES15/20 1/2″ 3/4″ Plastic Diaphragm Pump, a rigid coupling is perfect for it.

- Jaw Couplings: Pumps with high torque loads, such as centrifugal pumps and gear pumps.

- Magnetic Couplings: Pumps with no moving parts, such as diaphragm pumps. It is suitable for AOBL KES50 2″Metal Diaphragm Pump.

- Hydraulic Couplings: Pumps with misalignment, such as centrifugal pumps, diaphragm pump(Sanitary Diaphragm Pump) and gear pumps.

- Flexible Couplings: Pumps with misalignment and high vibration, such as centrifugal pumps and gear pumps.

- Synchronizing Couplings: Pumps that require speed synchronization, such as centrifugal pumps and gear pumps.

- Disc Couplings: Pumps with misalignment and high shock loads, such as centrifugal pumps and gear pumps.

- Elastomeric Couplings: Pumps with misalignment and high vibration, such as centrifugal pumps, diaphragm pump(KES80 3″ Plastic Diaphragm Pump) and gear pumps.

Factors to consider when choosing a pump coupling

The following are some of the factors to consider when selecting a pump coupling:

- The amount of power that needs to be transmitted. The coupling must be able to handle the amount of power that will be generated by the pump and motor.

- The amount of misalignment expected. The coupling must be able to absorb the expected amount of misalignment between the pump shaft and the motor shaft.

- The level of vibration present. The coupling must be able to handle the level of vibration present in the system.

- Cost of the coupling. Pump couplings can range in price from a few hundred dollars to several thousand dollars.

Summary

Overall, pump couplings are an important part of many pump systems. They help ensure that pumps and motors operate efficiently and safely.

As specialists in air operated diaphragm pumps and other fluid transfer pumps, AOBL offers Air Operated Double Diaphragm Pump, Electric Diaphragm Pump, Double Diaphragm Pump, Sanitary Diaphragm Pump, Filter Press Feed Pump and Parts & Accessories, and offers first class pumping and engineering innovations to meet the toughest and most demanding pumping challenges, feel free to contact us.