Diaphragm Pump Troubleshooting: A Practical Guide To Solving Problems

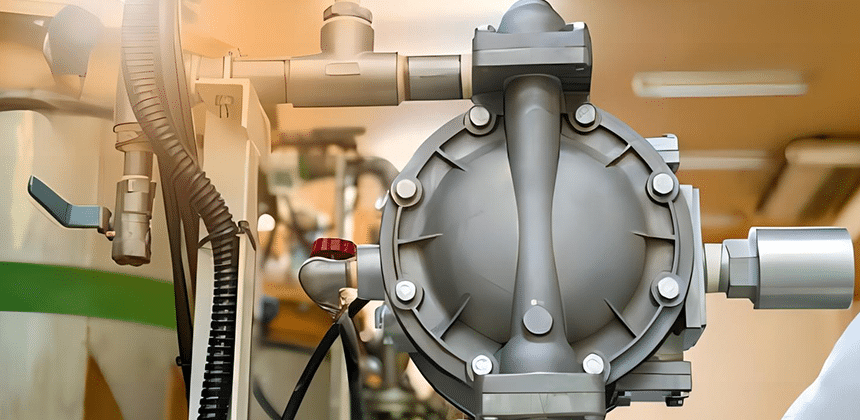

Diaphragm pump is a common pump equipment, its working principle is to use the movement of the diaphragm to achieve the suction and discharge of liquid. Air diaphragm pumps are widely used in different industries. Its corrosion resistance makes it ideal for conveying corrosive chemicals in the chemical industry. In the oil and gas industry, diaphragm pumps are used for liquid handling in oilfield extraction, natural gas transfer and handling processes. Pneumatic Diaphragm pumps are also widely used in the food and beverage industry to convey liquids such as juices, dairy products and beverages. Diaphragm pumps are commonly used fluid delivery equipment, the following are some common troubleshooting and solutions.

Common diaphragm pump failure

| Failure | Possible cause | Performance | Solution |

| Pump does not start | Power failure, motor damage, control system failure | Pump does not respond and does not start | Check the power supply, overhaul or replace the motor, repair or replace the control |

| Reduced pump flow | Worn diaphragms, clogged valves, leaking pump bodies | Significant reduction in pump flow | Replace worn diaphragms, clean or replace clogged valves, repair or replace pump body seal components |

| Unstable pump pressure | Unstable compressed air supply, air leakage from the pump body, valve failure | Pump pressure fluctuates or does not remain stable | Check the compressed air supply system, repair or replace the pump body sealing parts, adjust or replace the valve |

| Excessive pump noise | Loose pump parts, worn diaphragm, improper installation | Abnormal noise from the pump | Tighten pump components, replace worn diaphragms, reinstall the pump to ensure stability |

| Pump leakage | Broken diaphragms, aging seals, valve failure | Fluid leakage from pumps | Replace broken diaphragms, replace aging seals, repair or replace failed valves |

troubleshooting diaphragm pump steps

General troubleshooting steps

- Check the power supply: Make sure the diaphragm pump is properly connected to a reliable power source and check that the power lines are working properly.

- Check the compressed air supply: Make sure the compressed air supply to the diaphragm pump is stable and check that the air pressure adjustment valve is properly set.

- Check the liquid supply: Make sure the liquid supply line is clear and free of blockage, and check that the valve is open.

- Check the pump components: Check whether the diaphragm, valves, seals and connections are intact, and tighten loose parts.

- Check the pump body for air leakage: Use soapy water or gas leak detector to check the pump body for air leakage and repair the leakage point.

- Check the valve status: Ensure that the diaphragm pump’s import and export valves are in the correct position, and ensure that the valves are intact.

- Check the pump operation mode: Check the diaphragm pump operation mode is correct and follow the operation manual or instructions.

Importance of safe operation and proper use of tools

Wear appropriate personal protective equipment, such as gloves, goggles, and protective clothing, to protect yourself from potential hazards and injuries.

- Before operating the diaphragm pump,make sure you are familiar with the operation manual and follow the instructions for proper operation of the equipment.

- Use proper tools and equipment for repair and maintenance work and avoid using damaged or unsuitable tools.

- Never place fingers or other objects near moving parts during repair and maintenance to avoid entrapment or other injury.

- Turn off and disconnect the power supply and make sure the diaphragm pump is in a safe shutdown condition before making repairs or replacing parts.

- Inspect, maintain, and clean the diaphragm pump regularly to ensure proper operation and extended service life.

- If you encounter a complex or unsolvable problem, seek the help and guidance of a professional technician.

Please note that the steps and precautions listed above are general recommendations only and may vary depending on the diaphragm pump model and the environment in which it is used. Always refer to the operating manual and follow the relevant safety codes and instructions when operating and maintaining your diaphragm pump.

diaphragm pump preventive measures and maintenance recommendations

- Regular inspection and cleaning:

Periodically inspect the various components of the diaphragm pump, including the diaphragm,valves,and connections,to ensure they are not worn,loose,or damaged.

Clean the inside and outside of the pump body of dirt and sediment to keep the pump clear and clean. - Store and protect the pump properly:

When decommissioning or storing a diaphragm pump, store it in a dry, clean, and cool place away from moisture, heat, or corrosive materials.

For long-term storage, it is recommended that the pump be rust-proofed and that the pump be checked regularly to ensure that it is in good working order. - Regular replacement of parts:

According to the use of the diaphragm pump and the manufacturer’s recommendations, regularly replace the diaphragm, seals and other wearing parts to maintain the performance and reliability of the pump. - Pay attention to safe operation:

When operating the diaphragm pump, be sure to follow safe operating procedures and use the correct tools. Avoid overloading the pump and ensure that the operating conditions are within the design range. - Seek professional maintenance support:

If you encounter a complex repair or failure situation,it is recommended that you seek the help and support of a maintenance professional to ensure proper maintenance and repair of the diaphragm pump.

How to choose the right piping and size of the pump

Selection of the right piping and size requires consideration of the nature of the liquid, flow requirements, operating pressure and piping layout.

The following are some suggestions for selecting the right piping and size:

- Piping material: Choose a piping material that is compatible with the liquid being handled, common options include PVC, stainless steel and polyethylene. Make sure the piping material can withstand the chemical properties and temperature of the fluid.

- Pipe diameter: Select the appropriate pipe diameter based on the flow requirements of the diaphragm pump and the working pressure of the pipe. Too small a pipe diameter will increase the resistance of the fluid and reduce the efficiency of the pump, while too large a pipe may lead to low fluid flow rate, affecting the normal operation of the pump.

- Pipe length and elbows: Minimize the length of the pipe and the number of elbows, which can reduce the resistance of the fluid and pressure loss.Too long piping and too many elbows will lead to reduced flow and pressure drop of the pump.

- Support and fixation: Ensure that the piping system is properly supported and fixed to prevent the piping from vibration or external forces,thus reducing the load and vibration on the diaphragm pump.

- Valves and accessories: Properly install appropriate valves and accessories in the piping system in order to control flow,regulate pressure and facilitate maintenance.

Reduce the risk of icing: An effective solution to reduce pump air pressure

- Reduce air pressure: Reducing the air supply pressure required by the diaphragm pump reduces humidity and temperature changes in the gas, thereby reducing the risk of icing. Reduce the air supply pressure by adjusting the air pressure regulating valve or pressure reducing valve.

- Increase the pump size: Selecting a larger size diaphragm pump allows you to operate at a lower speed, reducing the rate of air flow through the center of the pump body and thus reducing the possibility of temperature changes and icing.

- Use an exhaust: Connect the pump exhaust port away from the pump body to vent cold air to an area away from the pump and reduce the risk of icing.

- Install an air line filter: Installing an air line filter with a water collector collects condensate and discharges it through the discharge port, reducing the possibility of moisture entering the pump body and icing.

- Install air line heater: Installing air line heater near the exhaust port can increase the exhaust temperature to keep it above the freezing point and avoid the icing problem.

- Air compressor dryer to adjust pressure dew point temperature: Use an air compressor dryer to adjust the pressure dew point temperature to ensure that the moisture in the exhaust is effectively removed, reducing the risk of moisture entering the pump body and icing.

By reducing the air pressure of the diaphragm pump and taking appropriate preventive measures, you can effectively reduce the risk of icing and protect the normal operation and service life of the diaphragm pump. In practice, appropriate methods and solutions should be selected according to the specific situation, and regular inspection and maintenance of equipment to ensure its normal operation.

Summary

AOBL diaphragm pumps are exceptional water treatment devices that provide exceptional performance and reliability for a wide range of applications and industries. They are known for their high efficiency, long life and low maintenance costs, making them a preferred choice for many users. AOBL diaphragm pumps utilise advanced diaphragm technology to efficiently pump a variety of fluids, including wastewater, sewage and chemicals. If you are interested in air diaphragm pumps or have any questions, welcome to contact AOBL’s professional engineer team to obtain equipment quotations or consult solutions.