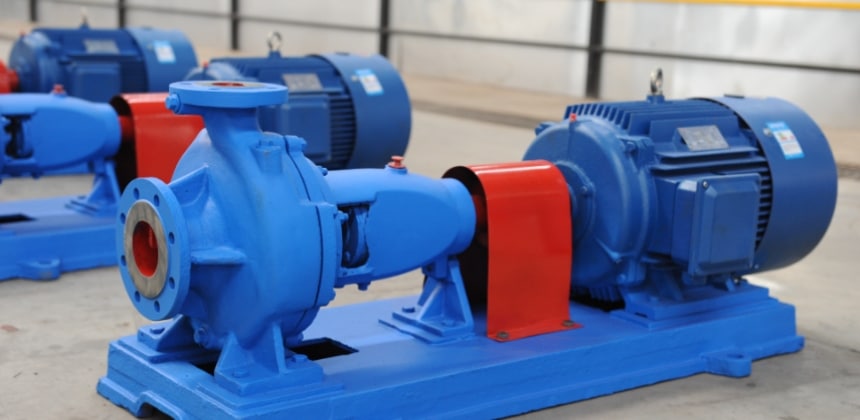

Single Stage Centrifugal Pump

Single stage centrifugal pump is a kind of basic equipment widely used in industry, agriculture, construction and municipal engineering. Its main function is to push the liquid from low-pressure area to high-pressure area by centrifugal force, which is widely used for the transportation of clear water, sewage, chemical liquid and other media. Due to its simple design and reliable operation, single-stage centrifugal pumps not only have a wide range of applications in daily water treatment, fire-fighting systems, heating, ventilation and air-conditioning (HVAC), but also become the preferred pump type in many industries due to its high efficiency, low cost and easy maintenance.

Working Principle of Single Stage Centrifugal Pump

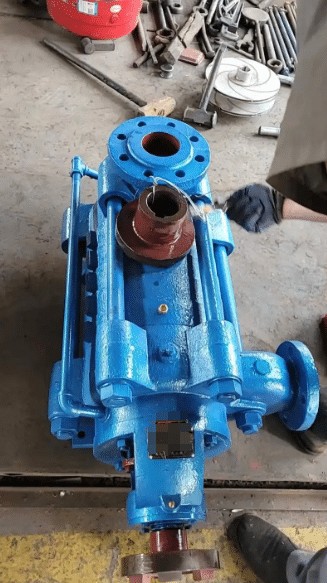

The working principle of the single stage centrifugal pump is very simple. The liquid enters the pump chamber from the inlet of the pump, and under the rotating action of the impeller, the liquid is subjected to the action of centrifugal force, and the speed increases rapidly. The liquid is pushed to the outlet of the pump through the flow channel of the impeller, thus completing the transportation of the liquid. Through the high-speed rotation of the impeller, enough pressure is generated inside the pump to push the liquid to flow.

Since there is only one impeller, the single-stage centrifugal pump is mainly used for occasions with high flow rates and medium head requirements. It is capable of providing a steady flow rate and a more uniform output pressure, and is suitable for most applications that require continuous transfer of liquids.

Design Features

- Compactness: Single stage centrifugal pump has simple structure and small size, which is very suitable for places with limited space.

- High efficiency: The pump body design is optimized for the shortest fluid path, which can reduce the energy loss of the liquid and improve the efficiency of the pump.

- Easy to maintain: A small number of parts make single stage centrifugal pumps relatively easy to maintain, usually requiring less repair work and downtime, reducing maintenance costs.

Fields of Application

Single stage centrifugal pump has a wide range of applications covering many industries:

- Municipal engineering: for urban water supply, sewage drainage and fire fighting systems.

- Agricultural irrigation: to provide a stable source of irrigation water for agriculture and horticulture.

- Industrial applications: for chemical liquid transportation, coolant circulation, oil-water separation and other industrial processes.

- HVAC (Heating, Ventilation and Air Conditioning) systems: for cooling and heating systems in buildings to ensure proper operation of water circulation systems.

- Water treatment systems: for clear water and sewage treatment, ensuring effective management and purification of water quality.

Technical Standards

Single-stage centrifugal pumps are designed to comply with a number of international standards to ensure performance and safety:

- DIN 24255 / EN 733: European standards that specify pump dimensions, efficiency and performance requirements to ensure consistency and compatibility of centrifugal pumps.

- ISO 2858 / ISO 5199: mainly applicable to the chemical and petroleum industries, covering pump strength, vibration control and operating conditions.

- API 610: Standard applicable to the oil and gas industry, ensuring pump durability and reliability.

- ANSI B73.1: American standard, applicable to the chemical industry, defines pump dimensions, material selection and construction requirements.

Difference between Single- Stage Centrifugal Pumps and Multi-Stage Centrifugal Pumps

| Comparison Item | Single-Stage Centrifugal Pump | Multi-Stage Centrifugal Pump |

| Working Principle | One impeller increases the pressure of the liquid. | Multiple impellers increase pressure step by step. |

| Head and Pressure | Low head, suitable for 20-150 meters. | High head, suitable for high-pressure and high-head applications. |

| Applications | Municipal water supply, water treatment, agricultural irrigation, etc. | Deep well pumping, boiler feed water, fire protection systems, etc. |

| Structural Complexity | Simple structure, easy maintenance. | Complex structure, difficult maintenance, higher cost. |

| Cost | Low cost, suitable for budget-limited applications. | Higher cost, suitable for high-demand applications. |

| Efficiency | High efficiency, suitable for large flow, low pressure applications. | Lower efficiency, suitable for high-pressure scenarios. |

| Maintenance and Inspection | Simple maintenance, short downtime. | Complex maintenance, longer downtime. |

| Installation Space | Requires less space, suitable for confined areas. | Requires larger space, suitable for high-head, high-power applications. |

Difference between Single- Stage Centrifugal Pumps and Multi-Stage Centrifugal Pumps

Advantage Analysis of Single Stage Centrifugal Pump

- High efficiency: Single stage centrifugal pump achieves high efficiency through optimized impeller and flow channel design, suitable for medium and low pressure liquid transfer.

- Low cost: Compared with multi-stage centrifugal pumps, single stage centrifugal pumps have simple structure and lower cost, which is suitable for occasions with limited budget.

- High reliability: single-stage centrifugal pumps are designed and manufactured to withstand the rigors of long-time operation and low failure rates, making them suitable for environments that require stable operation.

- Simple operation: simple operating system, high degree of automation, does not require complex operating skills, suitable for a variety of personnel.

Single Stage Centrifugal Pump Limitations and Precautions

Although single stage centrifugal pumps offer many advantages, they are not suitable for all situations. Here are some limitations to be aware of:

- Restricted pressure range: single stage centrifugal pumps are suitable for low to medium pressure applications, for situations where high head is required, a multi-stage centrifugal pump should be selected.

- Not suitable for highly viscous media: If highly viscous liquids are being conveyed, the efficiency of single-stage centrifugal pumps will be significantly reduced and it may be necessary to select a specially designed pump model.

- Not applicable to media containing solid particles: single-stage centrifugal pumps are mainly suitable for clean liquids, if the liquid contains solid particles, it may lead to clogging or damage to the pump.

How to Select a Single Stage Centrifugal Pump

The following factors need to be considered when selecting the right single stage centrifugal pump:

- Flow and head requirements: Make sure the pump can meet the required flow and head to ensure the normal operation of the system.

- Media characteristics: Select the appropriate pump material and design according to the temperature, viscosity, corrosiveness and other characteristics of the conveyed liquid.

- Energy efficiency and cost: choose a highly efficient pump type to reduce operating costs and ensure long-term stability.

- Installation space and maintenance requirements: according to the site installation conditions to select the appropriate pump type, such as tight coupling, long coupling or vertical installation.

Summary

Single stage centrifugal pump is widely used in various industries, especially in water treatment, water supply, agricultural irrigation and other fields, because of its simple design, efficient operation and low cost. By understanding the basic principles, advantages, applications and differences between single-stage centrifugal pumps and multistage centrifugal pumps, it can help users make the best choice under different working conditions and improve the efficiency and long-term stability of the system.

By choosing AOBL pumps, you will get one-stop solution for efficient liquid transportation. We not only supply single-stage centrifugal pumps for high flow and low pressure applications such as municipal water supply, wastewater treatment and agricultural irrigation, but also multi-stage centrifugal pumps to meet the demand for high head and pressure such as deep well pumping and boiler water supply. Whether you need energy efficient pumps or high performance high pressure pumps, AOBL Pumps can provide customized solutions. In addition, we also provide a wide range of pumps such as self-priming pumps, diaphragm pumps, gear pumps and other pumps, which are widely used in the chemical, petroleum, food, pharmaceutical and other industries, to ensure that they can meet the needs of all kinds of complex working conditions.