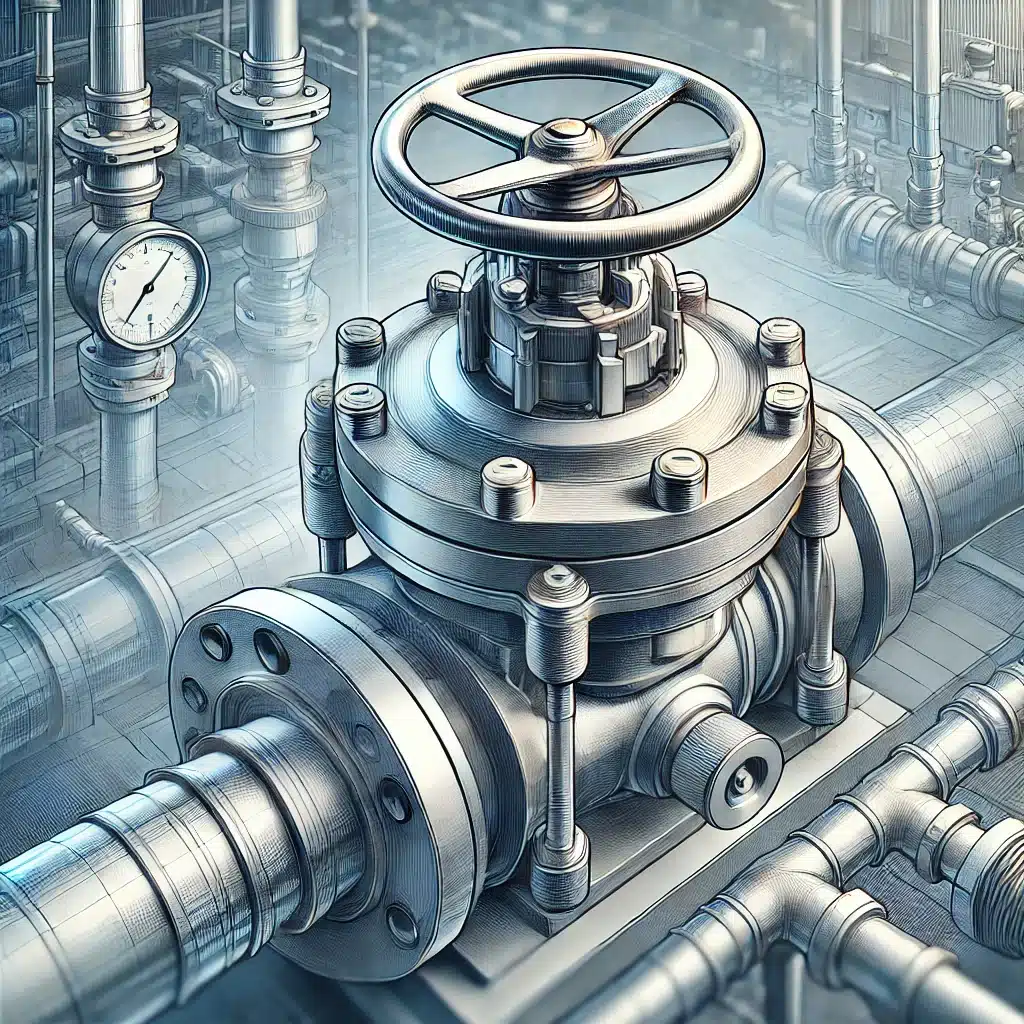

Air Release Valve

In any pumping system, the presence of trapped air can be a silent disruptor, leading to reduced efficiency, increased operational costs, and potential system damage. One of the simplest yet most effective solutions to this problem is the air release valve. As a pump expert, I can attest to the critical role that air-release valves play in maintaining the health and performance of fluid handling systems.

What are air release valves?

An air release valve is a device designed to automatically release air pockets that accumulate in a liquid system. As liquid flows through pipelines, air can enter the system through dissolved gases, leaks, or during maintenance activities. If not managed properly, this trapped air can cause a range of issues, including pressure fluctuations, reduced flow rates, and even physical damage due to water hammer effects. Air release valves work by allowing the air to escape, thus maintaining a smooth and efficient flow.

Why are air release valves important?

- Enhancing system efficiency: Trapped air can significantly impact the efficiency of pumps and piping systems. Air pockets act as obstructions, reducing the effective flow area and increasing the workload on pumps. By removing these air pockets, air release valves help restore and maintain optimal flow conditions.

- Preventing pressure surges: Sudden air release or entrainment can lead to pressure surges, commonly known as water hammer, which can damage pipes, fittings, and other components. Air release valves manage air accumulation, preventing these dangerous surges and protecting your equipment.

- Reducing energy consumption: Air pockets can cause pumps to work harder than necessary, increasing energy consumption. By eliminating air, air release valves help pumps operate within their designed parameters, leading to lower energy costs.

- Extending equipment lifespan: Consistent air release reduces the mechanical stress on pumps and pipes, which helps to extend the lifespan of your equipment. Less stress means fewer repairs and replacements, saving you time and money.

Types of Air Release Valves

There are several types of air release valves, each designed for specific applications:

Air release valves: Designed to continuously release small amounts of air from high points in a system.

Air/Vacuum valves: Allow large volumes of air to be expelled during filling or admitted during draining of a pipeline, preventing vacuum conditions.

Combination air valves: Provide both air release and air/vacuum functions, making them versatile for various applications.

Pumps Suitable for Air Release valves

Air release valves are suitable for various types of pump systems, particularly in the following pump types:

Centrifugal Pumps

Centrifugal pumps are among the most common pump types, widely used in water supply, wastewater treatment, and industrial applications. These pumps can easily accumulate air at high points in the pump casing and pipelines, leading to cavitation and reduced efficiency. Therefore, equipping them with air release valves is necessary.

Submersible Pumps

Submersible pumps used in wastewater and drainage applications frequently encounter air, especially during startup and shutdown. Air release valves can effectively remove this air, ensuring smooth operation of the pump.

Self-Priming Pumps

Self-priming pumps need to expel air from the pump chamber during startup to achieve self-priming. Air release valves help these pumps expel air more quickly and efficiently, improving startup performance.

Progressive Cavity Pumps

When handling viscous or multiphase fluids, progressive cavity pumps may trap air, affecting pumping efficiency. Air release valves help eliminate air, improving the stability and efficiency of the system.

Diaphragm Pump

Diaphragm pumps are often used to transport chemicals or liquids containing particles, which can generate bubbles during transport. Air release valves help prevent these bubbles from affecting the pump’s delivery capacity and pressure.

Plunger and Piston Pumps

These pumps are used for high-pressure applications and are prone to air entrainment during liquid flow. Air release valves can reduce the impact of air on pump efficiency, ensuring stable pressure output.

Selecting the Right Air Release Valve

Size and type: Ensure the valve size matches the flow requirements and the type suits your application.

Material compatibility: The valve material should be compatible with the fluid to avoid corrosion or chemical reactions.

Installation location: Proper placement, typically at system high points or along the pump discharge, is crucial for optimal performance.

Summary

Air release valves are beneficial for any pump type that may accumulate air, especially in high points or applications with frequent pump starts and stops. They not only enhance pump efficiency but also reduce cavitation, minimize pressure fluctuations, and extend the lifespan of pumps and system components. Selecting the right type of air release valve to pair with your pump can significantly improve the overall performance of the system.

Choosing the right pump and ensuring it operates efficiently with the correct components, like air release valves, is crucial for optimal performance in any fluid handling system. At AOBL, we specialize in designing and manufacturing custom pumps tailored to your specific needs. Whether you’re looking for solutions to enhance efficiency, reduce maintenance costs, or tackle complex fluid challenges, our expert team is ready to assist you.