Pump Volute of Centrifugal Pump

What is a pump volute?

Centrifugal pumps are an indispensable piece of equipment in modern engineering, and one of the key design elements is the pump volute, or worm casing. This simple yet delicate component plays a vital role in the operation of the pump, so let’s take an in-depth look at its design and function.

Basic construction of a pump volute

The worm casing is the housing of a centrifugal pump and is usually helical or screw-shaped. Its interior is designed to maximize energy conversion, converting the kinetic energy of the liquid into static pressure. While it may be simple in appearance, there is sophisticated engineering behind it.

- Suction inlet: Located in the center portion of the worm housing where fluid enters the pump. The suction port is usually connected to a pipe or other fluid source.

- Worm gland: The worm gear is a flow-guiding structure inside the worm housing, usually in the shape of a spiral. Its purpose is to guide the fluid into the pumpwheel, helping to increase the velocity and kinetic energy of the fluid.

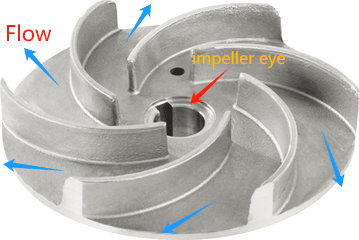

- Pump wheel (impeller): The pump wheel is the key component of a centrifugal pump and usually consists of a series of curved vanes. The rotation of the pump wheel generates centrifugal force, which throws the fluid away from the impeller and increases its kinetic energy.

- Outlet bore: Located on the side of the casing, used for fluid to leave the pump casing and continue on to a pipeline or other system.

- Pump shaft: The pump shaft is the shaft that connects the motor to the pump wheel and transmits the rotational motion of the motor to the pump wheel.

- Shaft seals and sealing devices: devices used to prevent fluid leakage from the pump casing, usually located at both ends of the pump shaft.

- Bearings: Used to support the pump shaft, reduce friction, and allow the shaft to rotate smoothly.

Energy conversion principle

When the liquid rotates through the pump vanes of the centrifugal pump, the centrifugal force generated by the pump vanes pushes the liquid toward the worm case. At this point, the liquid flows in from the impeller eye, generating a negative pressure at the mouth, which enters between a pair of veins, and then because of the centrifugal force thrown radially outward from the center of the impeller, this centrifugal force increases the flow rate of the liquid, which can be converted into pressure.

According to Bernoulli’s theory, if the flow rate is constant and the flow path area is changed, then the pressure and velocity will change accordingly. As the liquid flows out of the channel, the flow path area gradually increases. As the velocity decreases, the pressure increases, essentially the effect of the centrifugal impeller, which converts velocity into pressure.

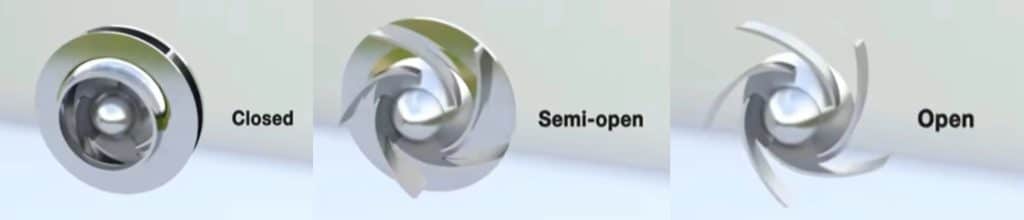

There are three types of impellers: closed impellers, semi-open impellers, and open impellers.

Functions of pump volute

- Directing fluid to the pumpwheel: The worm design of the worm housing helps direct fluid to the pumpwheel. The shape of the tongue and the curved structure of the inside of the worm gear effectively directs the fluid to the vanes of the pumpwheel.

- Increased fluid velocity: The design of the worm gear allows the fluid to gain a higher velocity before entering the pumpwheel. This helps increase the rotational kinetic energy of the pumpwheel and improves pump efficiency.

- Converts kinetic energy: As the pumpwheel rotates, the fluid inside the worm housing is thrown away from the impeller, creating centrifugal force. This converts the kinetic energy of the fluid into pressure energy, which creates head and allows the fluid to be pumped where it is needed.

- Pressure smoothing: The shape of the worm gear helps to smooth the flow of the fluid, reducing pressure fluctuations and contributing to the stability of the pump.

- Reduced swirl losses: Through the proper design of the worm gear, swirl losses can be reduced, helping to increase the efficiency of the pump.

The function of the pump casing is to maximize pump performance by optimizing fluid guidance, increasing fluid velocity, converting kinetic energy, smoothing pressure, and reducing vortex losses. Properly designed worm casings are critical to the performance of centrifugal pumps.The CQF-Z Self Priming Magnetic Pump features a self-priming design and is available in flow rates ranging from 220 LPM to 550 LPM.

Summary

Pump volute, a crucial design element in centrifugal pumps, with its delicate internal structure and clever combination with Bernoulli’s principle, not only provides an external shield for the pumping system, but also plays an indispensable role in the conversion of liquid energy. Its spiral shape, gradual expansion and synergy with the pump vanes make it a masterpiece of fluid mechanics.

AOBL, as an expert in air operated diaphragm pumps and other fluid transfer pumps, offers not only magnetic pumps and centrifugal pumps, but also air operated diaphragm pumps, filter press feed pumps, progressive cavity pumps and chemical pumps, etc., please feel free to contact us.