Self Priming Pump

A Self-Priming Pump stands as a vital innovation in fluid handling, designed to overcome the limitations of traditional centrifugal pumps. Unlike conventional systems that require manual priming or external mechanisms, self-priming pumps automatically evacuate air from the suction line and start fluid transfer with ease. This unique ability makes them indispensable in applications where consistent priming is a challenge, including sewage handling, industrial processes, and agricultural irrigation.

What is a self-priming pump?

Self-priming pumps are pumps that are capable of removing air from the suction piping to start transferring liquid without manual priming. This feature makes it particularly suitable for scenarios where the pump needs to be mounted above a liquid source or where the suction line may not always be filled with liquid.

Self-Priming Pump Applications

- Agricultural irrigation: For field irrigation, well water extraction, small rural drainage system.

- Industrial water: Circulating water, cooling water, waste water treatment.

- Sewage treatment: Transportation of sewage, wastewater, suitable for fluids containing impurities.

- Chemical industry: Transportation of corrosive liquids and chemical raw materials.

- Oil and gas: Transportation of oil, fuel and high viscosity liquid.

Working Principle of Self-Priming Pumps

The structure of self-priming pumps is similar to that of ordinary centrifugal pumps, which mainly includes impeller, pump casing, suction pipe, discharge pipe, etc. However, self-priming pumps usually have a vacuum chamber inside the pump casing. However, self-priming pumps usually set up a vacuum chamber inside the pump casing, which is the key to realize the self-priming function of self-priming pumps.

- Initial state: Before the pump starts, the pump casing and suction pipe are filled with air.

- Liquid introduction process: When the pump starts, the impeller rotates at high speed, forming a low-pressure area in the pump casing. Due to atmospheric pressure, the liquid is pressed into the suction pipe and enters the pump casing through the inlet.

- Emptying process: The liquid into the pump casing will be gradually discharged from the air inside the pump casing, when the pump casing is full of liquid, the self-priming process is completed.

- Continuous work: The liquid is thrown out by the impeller and discharged from the discharge pipe, forming a continuous liquid flow.

Types of Self-Priming Pumps

There are several types of self-priming pumps, each designed to handle specific fluid characteristics and operating conditions.

Positive Displacement Pumps

Precise delivery of liquids by mechanical movement of a piston or diaphragm. Capable of handling high viscosity liquids such as oils, syrups, etc. And good adaptability to liquids containing solid particles. Precise transportation of liquids by mechanical movement of pistons or diaphragms. Capable of handling high viscosity liquids such as oils, syrups, etc. And good adaptability to liquids containing solid particles. Including pneumatic and electric drive methods, chemical pumps, etc., suitable for a variety of applications, usually with self-priming capability.

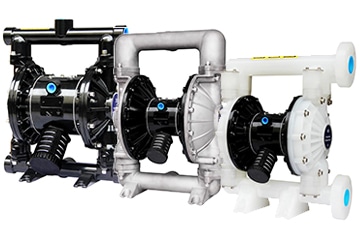

Diaphragm Pump

Utilizes the reciprocating motion of the flexible diaphragm to generate suction and pressure to push the fluid. Diaphragm pump suitable for handling corrosive fluids such as acids and alkalis. Highly resistant to fluids containing solids or impurities. AOBL air operated double diaphragm pumps are driven by compressed air to handle a wide range of fluids and are often used where self-priming is required.

The Difference Between Self-Priming and Centrifugal Pumps

- Self-priming function: The biggest advantage of self-priming pumps is the ability to suck in liquid at start-up without filling the pump, especially suitable for unstable liquid levels or where quick start-up is required.

- Application Flexibility: Self-priming pumps can handle liquids containing gas, solids or corrosive liquids, whereas ordinary centrifugal pumps are more focused on efficiency and are suitable for efficient transportation of clean liquids.

Self-Priming Pump Selection

Fluid Properties

- Viscosity: According to the viscosity of the liquid, select the pump suitable for viscous liquids (such as self-priming positive displacement pumps or large diameter pump chamber design).

- Corrosivity: Corrosive liquids require the use of pumps made of corrosion-resistant materials, such as stainless steel, PVDF or polypropylene.

- Solid particle content: For liquids containing solid particles, should choose to design a wide channel or anti-clogging function of the self-priming pump.

- Bubble content: Self-priming pumps are suitable for handling liquids containing gases, and can effectively complete fluid transportation.

Performance Parameters

Determine the amount of fluid to be conveyed, and select a model that meets the head requirements based on the height and pressure at which the fluid needs to be lifted in the system. The suction range of self-priming pumps (the vertical distance from the liquid level to the pump inlet) needs to meet the application requirements, generally the maximum suction range of self-priming pumps is 5-8 meters.

Use of The Environment

High temperature fluids require pumps made of high temperature resistant materials. Determine whether the pump needs to operate above the liquid level and whether there is enough installation space. For flammable and explosive environments, an explosion-proof self-priming pump should be selected.

Material Selection

- Clean water or ordinary liquid: Cast iron, carbon steel and other materials can be selected.

- Corrosive liquids: Corrosion-resistant materials such as stainless steel, PVDF, polypropylene, etc. are optional.

- Particle-containing liquids: Wear-resistant materials such as ceramics or reinforced plastics.

System Compatibility

Ensure that the pump connections match the piping system. If automated control is required, choose a self-priming pump equipped with sensors and a frequency converter.

Summary

Self-priming pumps are the perfect combination of efficiency and practicality to solve the challenges of air handling in fluid transfer operations. Self-priming pumps are suitable for a wide range of industries while reducing maintenance requirements, making them the preferred choice of many professionals.

As a manufacturer of AOBL pumps, we are committed to providing efficient and reliable pump equipment, we understand the various needs of our customers in liquid transfer, we not only provide efficient equipment, but also provide customers with comprehensive technical support and customized services, welcome to contact us to customize professional water treatment solutions for you.