Centrifugal Pump Casing

In modern industrial and commercial applications, pumps are widely used in many fields, from water supply systems to chemical processes to sewage treatment. One of the core components of the pump, the pump casing, plays a vital role. More than just a simple housing, the pump casing carries the entire pump system in operation, influencing fluid flow and pressure changes. Understanding the function and characteristics of this indispensable component, the pump casing is essential to understanding the working principle and performance of the pump.

What is a pump casing?

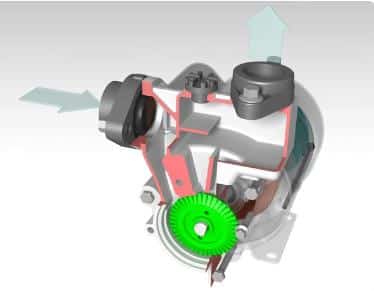

A pump casing is an important part of a pump, a housing that holds and protects the internal mechanical components. Typically made of metal, plastic, or other suitable materials, the primary function of the pump casing is to provide support, protection, and orientation of the fluid.

Role Of Centrifugal Pump Casing

- Holding the internal parts: The pump casing provides a space to hold and support the internal parts, including impellers, bearings, seals, etc. The pump casing provides a space to hold and support the internal parts. These parts are mounted inside the pump casing to ensure the solidity and reliability of the pump.

- Directs the fluid: The design of the pump casing can affect how the fluid flows and the distribution of the flow rate. Typically, the design of the inside of the pump casing directs the fluid entering the pump so that it flows smoothly through the impeller is accelerated, and then discharged through the outlet port.

- Increased pressure: The shape and construction of a centrifugal pump’s casing can help increase the pressure of the fluid. The shape of the pump casing compresses and accelerates the fluid as it passes through the pump casing and into the impeller, thereby increasing the pressure of the fluid and allowing it to flow smoothly out of the pump body.

- Protecting internal components: The pump casing also serves to protect internal components from external environmental factors that can cause damage to the pump’s internals. For example, it prevents impurities and particles such as corrosive liquids, water, etc. from entering the pump, and protects key parts such as impellers and bearings.

- Connection ports: Pump casings typically have inlet and outlet ports and connection ports for connecting piping systems and other equipment. These connection ports allow the pump to be easily connected to piping systems and other equipment for fluid transfer.

The pump casing of a centrifugal pump plays a vital role in the operation of the pump, which not only provides support and protects the internal parts, but also guides the fluid, increases the pressure, and connects with other equipment through the connection ports, thus ensuring the normal operation and efficient work of the centrifugal pump.

Other Types Of Pump Housings

Ram pump casing: Ram pump casings are the housings used in ram pumps and are usually made of metal. They house and support the plunger, seals, and other internal components, and are designed to control and direct the flow of liquid through the interior of the pump casing.

Screw pump casings: Screw pump casings are housings used for screw pumps and are usually made of metal or alloy materials. They house the screw and control and direct the flow of liquid through the design of the pump casing, resulting in increased pressure and flow transfer.

Diaphragm pump housings: Diaphragm pump housings are housings used for diaphragm pumps and are typically made of metal or plastic. They house the diaphragm, pump head, and other internal components, and are designed to control and direct the flow of liquid through the interior of the pump housing, allowing for suction and discharge of liquid.

Vacuum pump casings: Vacuum pump casings are housings used for vacuum pumps and are usually made of metal. They house the rotary vane, impeller, or other internal components and are designed to control and direct the flow of gases through the interior of the pump casing to create and maintain a vacuum.

Self-priming pump casing: Self-priming pump casings are the housings used for self-priming pumps and are usually made of metal or plastic. They house impellers, seals, and other internal components and are designed to control and direct the flow of liquid through the interior of the pump casing for self-priming and dewatering functions.

Advantages And Disadvantages Of Pump Casing

Advantages

- Provide structural support

- Protects internal components:

- Directing Fluid

- Provide connection ports

- Adaptable

Disadvantages

- Higher manufacturing costs

- Difficult to maintain

- Higher weight

- It may affect the pump performance

As a key component of centrifugal pumps, the pump casing has important functions and roles, but its advantages and disadvantages need to be weighed in the selection and design to ensure the normal operation and long-term stability of the pump.

Difference Between Pump Casing and Worm Casing

The pump casing of a centrifugal pump is mainly used to house and support the rotor and bearings inside, while the worm casing is mainly used to house and hold the impeller, and through its special design directs the fluid into the impeller and accelerates the rotation.

| Features | Pump Casing | Worm Casing |

| Definition | The housing of the pump houses and supports key components such as rotors, impellers and bearings inside. | The external housing of the impeller |

| Material | It is usually made of metal or alloy material. | Made of metal or plastic material. |

| Function | Hold and support internal components, Directs the fluid to the impeller. | Holds and secures impeller, directs fluid into impeller and accelerates rotation |

| Fluid Guide | Affects the way fluids flow and the distribution of flow velocity. | Directs the fluid into the impeller and changes its flow rate and direction. |

| Connection | It affects the flow pattern and velocity distribution of the fluid. | Usually attached to the pump casing. |

| Key Influencing Factors | Pump performance and efficiency, the way the fluid flows. | Rotational speed of the impeller, design of the inner wall of the worm gear. |

The pump casing of a centrifugal pump is mainly used to house and support the rotor and bearings inside, while the worm casing is mainly used to house and hold the impeller, and through its special design directs the fluid into the impeller and accelerates the rotation.

Summary

The pump casing of a centrifugal pump is one of its important components and plays a vital role in the normal operation and long-term stability of the pump. How to correctly select the use of the pump casing is a crucial step.

AOBL is a manufacturer of pumps, specializing in water treatment, providing a wide range of pumps, in addition to centrifugal pumps, covering pneumatic air operated diaphragm pump, sanitary diaphragm pumps, magnetic drive pumps, chemical pumps and many other types of pumps, sufficient for the needs of different industries and application scenarios. Please contact us to provide you with professional solutions.