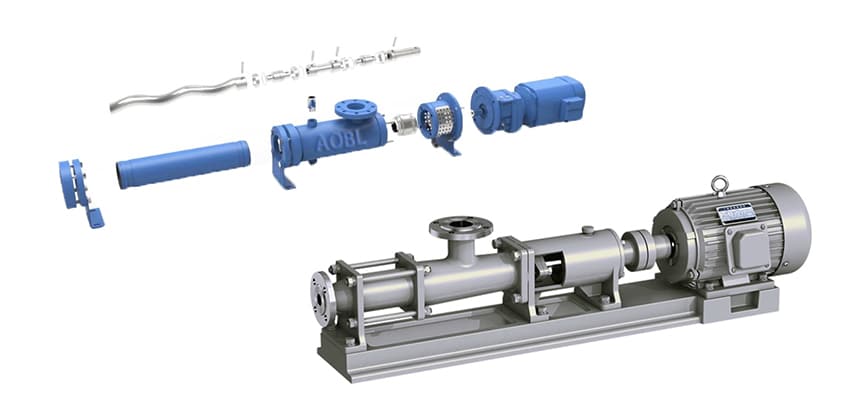

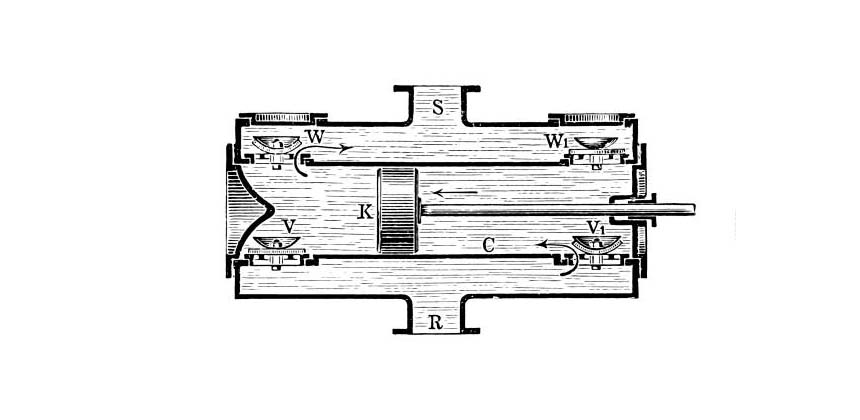

The eccentric screw pump is an internally meshed, closed displacement pump that can be used in virtually all industrial applications and for pumping low viscosity to viscous media due to the pump’s adaptability to the medium, smooth flow, and good suction performance. This progressive cavity pump has a small footprint, is available in low to high flow configurations, and is competitively priced.

Flow range: 0.6 m³/h – 150 m³/h

Maximum pressure: 1.2 Mpa

Speed range: 500 rpm – 960 rpm

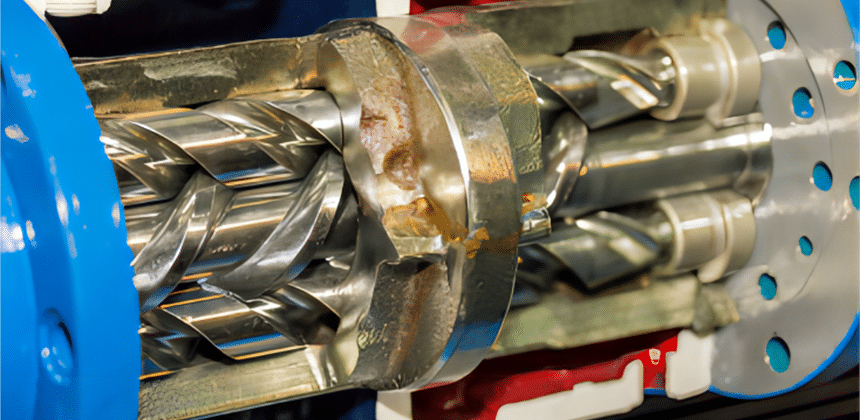

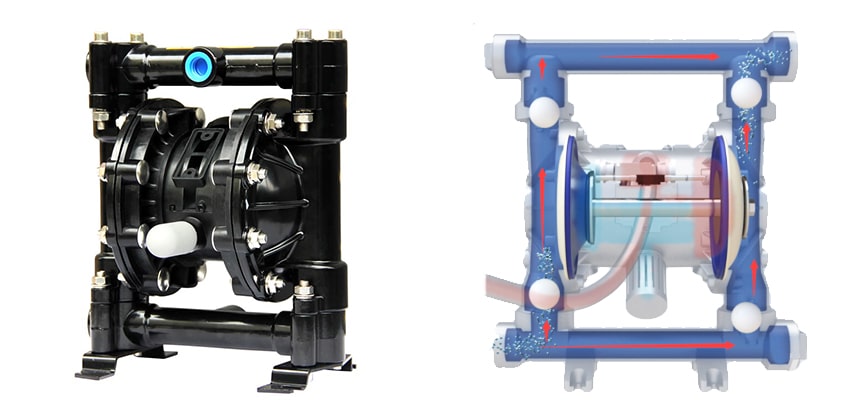

Eccentric screw pumps, also known as single screw pumps, helical rotor pumps, rely on the intermeshing of a screw and a bushing to produce a change in volume in the suction and discharge chambers to transport liquids. Due to the strong adaptability of this pump to the medium, smooth flow, good suction performance, pressure pulsation is small, in addition to transporting a variety of flowable media, but also can be transported to highly viscous media, containing hard suspended particles or solid particles of the media, media containing fibers.

AOBL eccentric screw pump adopts the block structure with flange drive, compact and economical, good regulation performance, wide range and high efficiency. A wide range of rotor/stator geometries are available, covering a wide range of products and applications.

Features

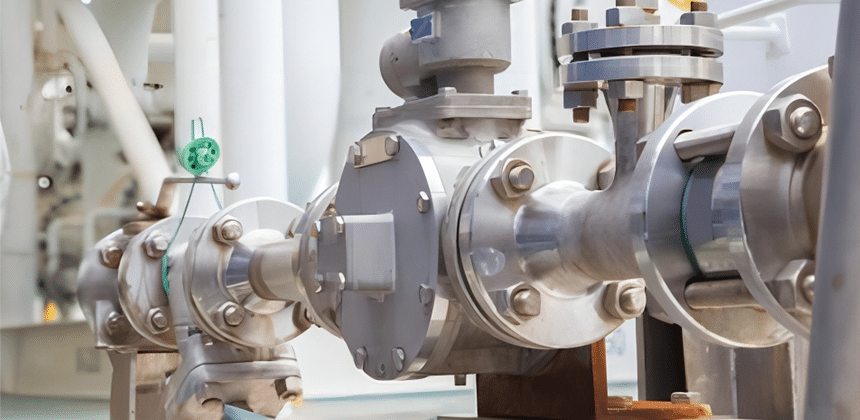

- Compact, space-saving design

- Selected drives and gearboxes with low-speed options to minimize pump wear

- Gentle, uniform pumping flow without dampers or condensers, especially suitable for sensitive pumping media

- Available in various rotor/stator geometries and with different shaft seals

- Reduced material costs due to design without drive housing, flexible coupling and shared base plate

Applications

- Petrochemical industry: light. Heavy oil, acid and alkali salt solution, all kinds of viscous paste. Emulsified slurry transportation, oil-water separation and waste oil recycling system, polymer transportation.

- Environmental protection: industrial. Domestic sewage treatment, oil sewage treatment, transport of sludge containing solid particles and short fibers. Turbid water, oil-water separation and exhaust gas engineering, coagulants and their chemical agents, measurement and addition, etc.

- Survey and mining: transportation of drilling mud, mining water supply and drainage, mining duster water supply, mine tunnel wall mortar. Concrete, etc.

- Medicine and food: transportation of medical ointment. Sugar paddle. Jam. Fermentation liquid. Honey. Cream. Starch paste. Toothpaste etc.

- Shipbuilding industry: bilge cleaning pumps, ship incinerator transfer pumps, oil and gas separator supporting pumps, cabin oil sewage and other media transportation

- Energy industry: transportation of various kinds of fuel oil, coal water slurry. Resin. Additives

- Paper industry: a variety of paper paddles, short fiber pulp transportation, slurry and wastewater treatment, chemical metering, raw material preparation, coating and coloring process

- Construction industry: transportation of cement mortar, paint, lime milk and other pasty liquids.

- Electrolyte treatment: various pastes . Emulsion . Suspension and can not be mixed and cut media transportation

- Mineral engineering: preparation and transportation of coal water slurry, production and preparation of kaolin and other materials, loading and grouting

- Mechanical engineering: oil-water mixtures. Metal-containing sludge. Metallurgical slurry. Waste tank emptying, etc.

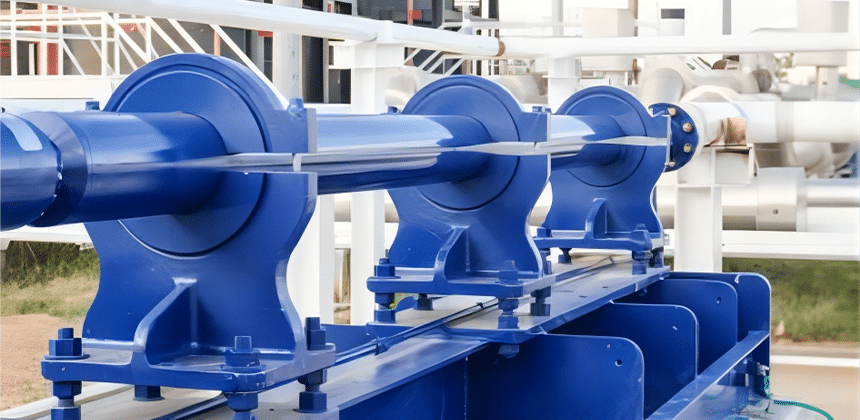

Field case

- Single screw pumps are used in wastewater treatment plants

- Single screw pump is used to transport sewage, PAM

FAQ

| Brand | AOBL |

| Maximum pressure | 0.6 Mpa, 1.2 Mpa |

| Maximum flow | 0.6 m³/h, 0.8 m³/h, 2 m³/h, 5 m³/h, 8 m³/h, 12 m³/h, 20 m³/h, 30 m³/h, 45 m³/h, 60 m³/h, 100 m³/h, 150 m³/h |

| Maximum speed | 500 rpm, 720 rpm, 960 rpm |

| Motor power | 0.55kW, 0.75kW, 1.5kW, 2.2kW, 3kW, 4kW, 5.5kW, 7.5kW, 11kW, 15kW, 18.5kW, 22kW, 37kW |

| Allows the particle diameter | 1 mm, 1.5 mm, 2 mm, 2.5 mm, 3 mm, 3.8 mm, 5 mm, 6 mm, 8 mm, 10 mm, 15 mm, 20 mm |