What is pneumatic pump?

A pneumatic pump is a type of pump that utilizes compressed air as a power source to propel a fluid. Unlike mechanical pumps that rely on electric motors or engines, pneumatic pumps operate through compressed air, so they are particularly suited to applications where electricity is not available or hydraulic power is not suitable. Pneumatic pumps are widely used in the chemical, food and beverage, pharmaceutical, and water treatment industries.

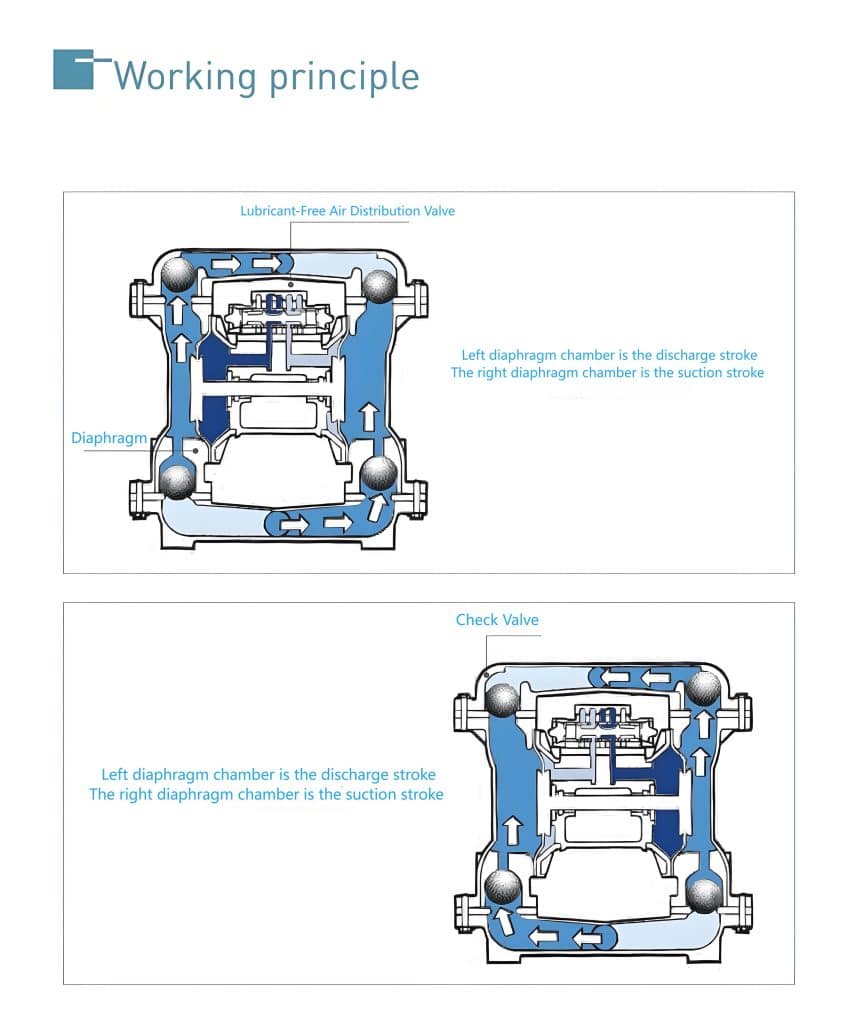

Working Principle of Pneumatic Pumps

Pneumatic pumps drive a piston or diaphragm inside the pump through compressed air, which produces a reciprocating motion that pushes the fluid. In the case of pneumatic pumps, for example, compressed air is applied alternately to both sides of the diaphragm, resulting in compression and expansion of the diaphragm, which in turn pushes the fluid through the pump. This principle of operation allows pneumatic pumps to provide a consistent flow rate for applications that require precise control.

Advantages of Pneumatic Pumps

- No electricity required: pneumatic pumps rely only on compressed air to operate, making them suitable for environments with limited electricity supply or where electrical hazards exist.

- Self-priming: Many pneumatic pumps are self-priming, allowing them to start working even if the pump is not filled with liquid.

- Durable: pneumatic pumps are capable of handling a wide range of liquids, including corrosive, viscous or particle-laden liquids, and can operate in harsh environments.

- Adjustable flow rate: by adjusting the pressure of compressed air, the flow rate of pneumatic pump can be controlled to meet different operational needs.

Application Areas of Pneumatic Pumps

Chemical and pharmaceutical industry: For conveying chemicals, solvents, acid and alkali liquids, etc.

Food and beverage processing: Dor conveying food ingredients, oils, syrups and other viscous liquids.

Water treatment: For conveying sludge, wastewater and other liquid wastes.

Mining and oil: Used in industries that need to handle fluids containing particles or viscous fluids.

Types of Pneumatic Pumps

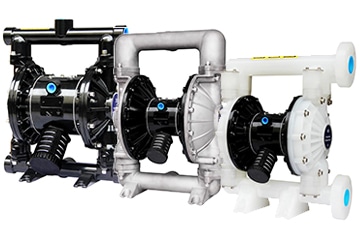

- Air operated diaphragm pumps

- Pneumatic piston pumps

- Pneumatic peristaltic pumps

Air operated diaphragm pump: Uses the reciprocating motion of a diaphragm to transfer fluids, and is suitable for conveying corrosive, viscous, or particle-containing liquids.

Pneumatic piston pump: Utilizes the reciprocating motion of a piston within a cylinder to propel a fluid, suitable for high pressure applications such as hydraulic testing.

Pneumatic peristaltic pumps: Rotating mechanism driven by compressed air, utilizing peristaltic action to propel fluids, suitable for conveying viscous or sticky liquids.

Pneumatic peristaltic pumps: Rotating mechanism driven by compressed air, utilizing peristaltic action to propel fluids, suitable for conveying viscous or sticky liquids.

What is a pneumatic system?

Pneumatic pumps are closely related to pneumatic systems because the operating principle of pneumatic pumps depends entirely on the compressed air supplied by the pneumatic system. Pneumatic pumps use compressed air to push the mechanical parts inside the pump body (such as a piston or diaphragm) in a reciprocating motion, which in turn pushes the liquid from the suction side to the discharge side. The key feature of pneumatic pumps is that they do not require electrical power and rely on compressed air to operate. These pumps are often used in hazardous environments or where power is unstable.

The Relationship Between Pneumatic Pumps and Pneumatic Systems

The pneumatic pump is the key component in the pneumatic system, and the two are closely connected through the compressed air and control system. The pneumatic system provides power for the pneumatic pump, while the pneumatic pump realizes fluid conveying. The design and adjustment of pneumatic system directly affects the performance of pneumatic pump, therefore, the two are interdependent, and jointly complete the fluid transportation task.

Summary

Pneumatic pumps are highly versatile pumps for specific applications that require compressed air to drive fluid transfer. However, they can be limited in certain environments due to their dependence on air supply and lower energy efficiency.

AOBL is a manufacturer specializing in the research, development, production and marketing of a wide range of pumps for industrial wastewater treatment and other applications. Besides air operated diaphragm pumps, we also have EODD diaphragm pumps, sanitary diaphragm pumps, filter press diaphragm pumps, progressive cavity pumps, vertical centrifugal pumps as well as pump accessories, please feel free to contact our professional team for your customized service!