What is Rubber Diaphragm?

Rubber diaphragm is a critical component widely used in engineering and industrial applications. Not only does it provide excellent sealing performance, it is also able to adapt to a wide range of environmental and pressure conditions. However, rubber diaphragm may be an unfamiliar term to many. We will explore what a rubber diaphragm is, how it works, and its importance in different industries and applications.

What is a rubber diaphragm?

A rubber diaphragm is a flexible membrane made of a rubber material designed to stretch or deform under pressure. It is commonly used in various applications, including mechanical devices, pumps, valves, and pressure vessels, to control the flow of fluids or gases.

Specificities

- Flexibility: Can deform or stretch in response to pressure changes.

- Sealing: Provides an effective seal between two chambers to prevent fluid or gas leakage.

- Durability: Rubber diaphragms are resistant to abrasion, tearing, and corrosion.

- Chemical Resistance: Depending on the type used, they can resist various chemicals and fluids without damage.

- Temperature resistance: they can work effectively over a wide range of temperatures.

Appliance

- Pumps

- Valves

- Pressure regulators

- Hydraulic Systems

- Controls

- Other special devices

How do rubber diaphragm work?

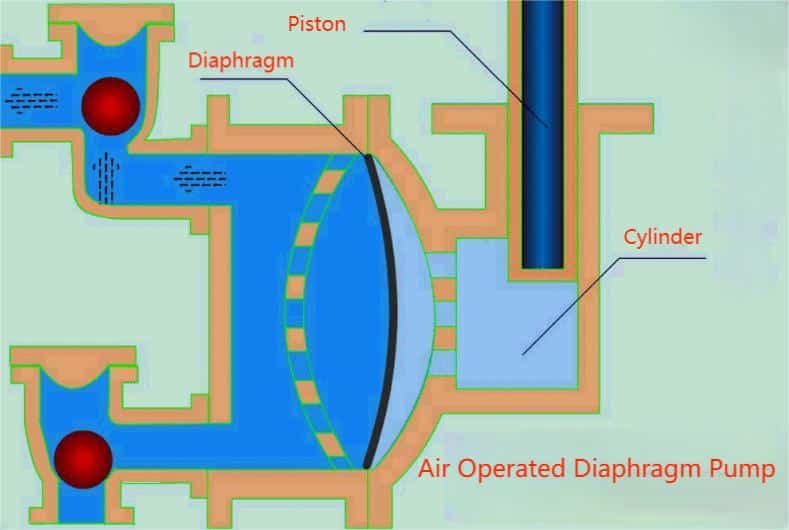

Pressure differentials cause the rubber diaphragm to move upward into one chamber or downward into another, allowing for some movement between the stationary and moving parts. Due to their low permeability to liquids and gases, rubber diaphragms keep the media separated on both sides of the diaphragm. They also ensure a consistent differential pressure between media and can provide a gasket function in the instrument flange.

Advantages and Disadvantages of Rubber Diaphragm

Advantages

- Good sealing: Provide good sealing, effectively preventing the leakage of liquid or gas.

- Good elasticity and flexibility: good elasticity and flexibility, so that the diaphragm can adapt to a variety of pressure changes and vibration environments.

- Corrosion resistance: usually has good corrosion resistance, and can resist the erosion of many chemical substances, to extend the service life.

- Good abrasion resistance: Good abrasion resistance, can withstand long-term use and friction.

- Easy processing and molding: Rubber materials are easy to process and mold, and can be manufactured into various shapes and sizes of diaphragms as needed.

Disadvantages

- Temperature limitation: the temperature range is limited, too high or too low a temperature may lead to rubber material performance degradation or failure.

- Easy aging: Long-term exposure to high temperatures, ultraviolet rays, chemical corrosion, and other factors, rubber materials are prone to aging, hardening, or cracking, reducing sealing performance and durability.

- Limited pressure resistance: Compared with metal or other materials, rubber diaphragms have relatively low-pressure resistance and cannot withstand excessive pressure.

- Restricted selection: Different types of rubber materials are suitable for different operating environments and media, and improper selection may affect performance and service life.

Rubber diaphragms are still a common and effective sealing and control element in many applications, but their scope of application and limitations need to be considered when selecting and using them.

Types of Rubber Used In Rubber Diaphragms

- Nitrile Rubber (NBR)

- Ethylene Propylene Diene Rubber (EPM, EPDM)

- Neoprene Rubber

- Styrene-Butadiene Rubber (SBR)

- Silicone Rubber (SiR)

Pumps Suitable for Rubber Diaphragms

Rubber diaphragms are suitable for many different types of pumps, especially for applications requiring good sealing and corrosion resistance.

Diaphragm pump: This is one of the most common pumps to utilize rubber diaphragms. Diaphragm pumps use a rubber diaphragm as the key component of the pump, which periodically expands and contracts to allow for the suction and discharge of liquids. The rubber diaphragm acts as a seal and pushes the liquid in this type of pump. AOBL KES50 boasts outstanding performance and efficiency in the marketplace. This versatile mobile pump handles abrasive liquids and suspended solids with best-in-class flow rates and minimal air consumption.

Peristaltic pump: Peristaltic pumps, also known as pipeline pumps, propel liquids by compressing flexible tubing. The rubber diaphragm can be used as part of the pipeline, used in contact with the compression device, and keep the pipeline and pump interface sealed.

Gear pump: In some specific gear pump designs, rubber diaphragms can be used as a sealing element to prevent leakage of liquid inside the pump. These pumps are often used to transfer viscous liquids or chemicals.

Centrifugal pump: In specific applications, rubber diaphragms can be used as sealing elements in centrifugal pumps to ensure pump stability and safety.

What is the hardness of the rubber diaphragm?

The hardness of rubber diaphragms can vary depending on the specific application requirements. Shore A hardness is commonly used to express the hardness of a rubber diaphragm and can range from a soft 30 Shore A to a hard 90 Shore A.

- For applications requiring greater flexibility and suppleness, lower durometer rubber diaphragms, such as those in the 30-60 Shore A range, may be preferred.

- For applications requiring higher abrasion and corrosion resistance, a higher durometer, such as those in the 70-90 Shore A range, may be preferred.

The choice of hardness depends on factors such as the specific operating environment, pressure requirements, temperature range, and chemical nature of the medium. In general, higher hardness usually means better abrasion resistance and durability, at the expense of a certain degree of elasticity and softness.

Summary

As a versatile mechanical component, the rubber diaphragm plays an important role in many industrial and engineering fields. Its excellent sealing properties, good elasticity, and corrosion resistance make it an indispensable component in many devices and systems.

AOBL, as a pump manufacturer, uses high quality materials and advanced technology to ensure reliable quality and stable performance. We offer a wide range of pump models including sanitary diaphragm pumps, porogressive cavity pump, magnetic drive pumps, diaphragm pump spare parts and pulsation dampers. If you need more information or have any questions, please feel free to contact us.