Specific Speed Of Pump

In the water treatment industry, the selection and design of pumps directly affect the efficiency and stability of the system. There are various performance parameters of pumps, among which specific speed, as a key performance parameter, plays an important role in the pump selection and optimization process. This article will discuss the definition of particular speed, calculation methods, and its importance in practical applications, to help you make more informed decisions in the selection and design of water treatment pumps.

Definition

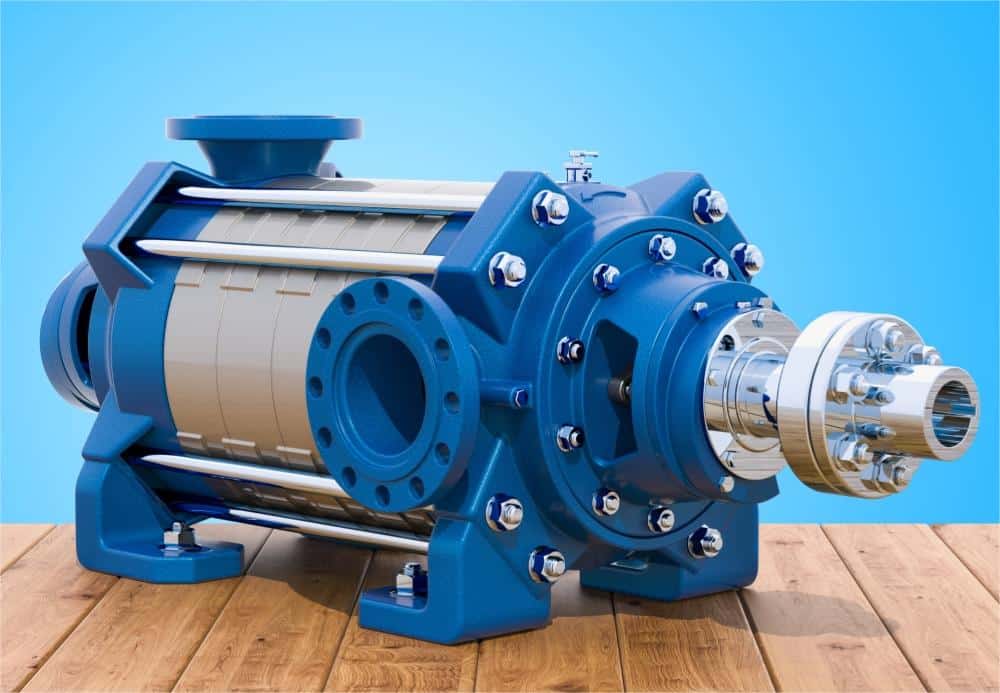

Pump-specific speed (Ns) is a dimensionless parameter used to characterize the type and performance of centrifugal pumps.

It is defined as if a pump is geometrically similar to an actual pump, its speed (N) per unit flow (Q) and per unit head (H) is called the specific speed.

Calculation Formula for Specific Rotational Speed

- N: Pump speed in revolutions per minute (RPM).

- Q: Pump flow, in cubic meters per second (m³/s).

- H: Pump head in meters (m).

Ns = N√Q / H^(3/4)

Specific speed is a useful parameter for comparing pumps of different sizes and designs. It can be used to predict pump efficiency, NPSH requirements, and operating stability.

Pump Types and Specific Speed

Different types of pumps have different specific speed ranges.

- Low-specific speed pumps (500-1000): These pumps have high heads and low flow rates. They are typically used for deep well pumping and high-pressure applications.

- Medium-specific speed pumps (1000-3000) have medium head and flow rates. They are the most common type of pump and are used in various applications, such as industrial and municipal water treatment.

- High-specific speed pumps (3000-9000): These pumps have low head and high flow rates. They are typically used for large flow rate applications, such as drainage.

Specific Speed and Pump Performance

Specific speed can affect several pump performance parameters, including:

- Efficiency: In general, pumps have higher efficiency at their best efficiency point (BEP), which is a specific operating condition defined by flow rate and head. Specific speed can be used to predict the location of the BEP and the overall efficiency of the pump.

- NPSH requirements: Net positive suction head (NPSH) is the available suction head required for a pump to avoid cavitation. High-specific speed pumps generally have lower NPSH requirements, meaning they can operate at lower suction pressures.

- Operating stability: Specific speed can also affect the operating stability of a pump. Pumps with too high or too low of a specific speed for the application may be more prone to cavitation, vibration, and other problems.

Selecting the Right Pump

In addition to specific speed, several other factors should be considered when selecting a pump, such as:

Material: The pump material must be compatible with the fluid being pumped.

Corrosion resistance: The pump must be able to withstand the corrosive environment.

Operating conditions: The pump must be able to operate at the required flow rate, head, and speed.

Size: The pump must be physically fit for the application.

Cost: The pump must be cost-effective for the application.

Specific speed is an important parameter in pump design and optimization. By understanding specific speed, engineers can design pumps that are more efficient, have lower NPSH requirements, and are more stable in operation.

Frequently Asked Questions (FAQ)

Q1: What is the optimum range of specific speed?

The optimum range of specific speeds depends on the specific application. In general, medium specific speed pumps (1000-3000) are suitable for most industrial and municipal applications.

Q2: How does specific speed affect pump efficiency?

Specific speed predicts pump efficiency. In the optimum range of specific speeds, the pump usually has the highest efficiency.

Summary

By understanding and calculating the specific speed of a pump, engineers, and technicians can optimize the pump’s performance and ensure efficient system operation. Specific speed is not only a parameter, but also an important tool to guide pump design and selection.

AOBL pump manufacturers not only increase pump reliability, but also reduce maintenance requirements. The optimized design reduces vibration and noise during operation, which reduces the failure rate and maintenance frequency. We offer diaphragm pumps, EODD diaphragm pumps, sanitary diaphragm pumps, progressive cavity pumps, chemical pumps, and Pump Accessories such as pulsation dampener, filter regulator lubricator, etc. Welcome to visit our website, our professional team is always ready to answer your questions.