Understanding Viscous Liquid Pump

Viscous liquid pumps are pumps specifically designed to handle highly viscous liquids, viscous liquids are those that are thick and poorly flowing. These types of liquids, such as oils, syrups, sludges and thick chemicals, require specific pump designs to efficiently transfer them into the system. Handling viscous liquids is a common occurrence in industries such as wastewater treatment, food processing and chemical manufacturing, and using the right pump can significantly improve operational efficiency.

Why do You Need A Viscous Liquid Pump?

Viscous liquid pumps are pumps specifically designed to handle viscous or highly viscous liquids. Viscous liquids flow poorly due to their thick nature, and conventional pumps (such as centrifugal pumps) are unable to transport these liquids efficiently. They have difficulty overcoming the high internal friction of the liquid, resulting in slower flow rates, increased energy consumption, and component wear. Therefore, the use of specially designed pumps for viscous liquids ensures smooth fluid transfer, avoids equipment damage, and improves efficiency.

Characteristics of Viscous Liquid Pumps

- Resistance to high viscosity: The ability to handle fluids with higher viscosity ensures that they can be drawn in smoothly and transported efficiently.

- Lower flow rates: Viscous fluids are often pumped at lower flow rates than conventional fluids, as higher viscosities require more thrust to overcome friction within the fluid.

- High pressure capability: In order to push viscous fluids, these pumps often need to be designed to withstand higher pressures to ensure that the fluid can be transported efficiently.

Common Types of Viscous Liquid Pumps

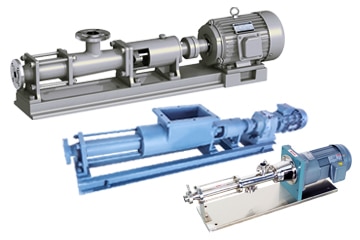

Progressive Cavity Pumps: As progressive cavity pumps, they are designed to handle highly viscous and sensitive liquids. These pumps use a rotor and stator to propel the liquid in a helical fashion, and are especially suited for transferring viscous sludges and pastes.

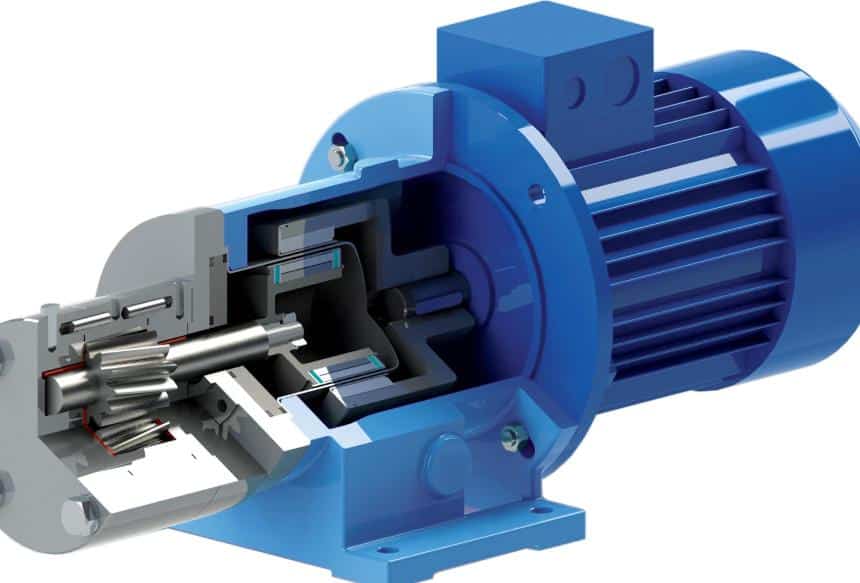

Gear Pump: Gear pumps are widely used to transfer viscous liquids such as oils and resins. Gear pumps push liquids through two meshing gears, ensuring continuity of liquid transfer by creating a steady, non-pulsating flow. Gear pumps are ideally suited for applications that require precise flow rates and consistent flow.

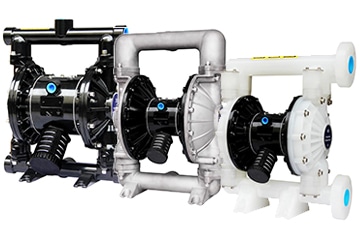

Diaphragm Pump: A diaphragm pump is a versatile pump capable of handling a wide range of viscous liquids. It creates suction through a diaphragm that moves back and forth, drawing liquid into the pump chamber and discharging it. This type of pump is suitable for applications that require self-priming and avoiding contamination.

Peristaltic pumps: Peristaltic pumps, also known as hose pumps, create a vacuum to pump liquids through a rotating roller or shoe that compresses the hose. Peristaltic pumps are particularly suited to handling very viscous or aggressive fluids and are commonly used in the chemical, food and pharmaceutical industries.

Troubleshooting Viscous Liquid Pumps

| Issue | Possible Cause | Solution |

| Pump not priming or low suction | 1. Inadequate priming. 2. Leaks in suction line. 3. Blocked suction line. | 1. Ensure sufficient liquid and remove air. 2. Repair leaks. 3. Clean suction line. |

| Low output flow | 1. High viscosity. 2. Inadequate liquid supply. 3. Low pump speed. | 1. Use a pump suitable for viscous liquids. 2. Increase temperature to lower viscosity. 3. Adjust pump speed. |

| Excessive noise | 1. Air in the pump. 2. Worn parts or debris. 3. Overloaded pump. | 1. Remove air and check for leaks. 2. Inspect and replace worn parts. 3. Reduce pump load or adjust selection. |

| Overheating | 1. High liquid temperature. 2. Overload operation. 3. Worn bearings/seals. | 1. Lower liquid temperature. 2. Reduce pump load. 3. Replace worn bearings/seals. |

| No liquid discharge | 1. Blocked discharge line. 2. High viscosity. 3. Poor seal causing leakage. | 1. Clean discharge line. 2. Adjust pump for high viscosity. 3. Replace seals. |

| Unstable flow | 1. Cavitation. 2. Viscosity fluctuations. 3. Loose or damaged parts. | 1. Ensure proper priming. 2. Maintain stable viscosity. 3. Inspect and replace damaged parts. |

How to Choose The Right Pump for Viscous Liquids?

- Viscosity of the liquid: Highly viscous liquids require more robust pumps, such as screw pumps or diaphragm pumps.

- Flow requirements: Some pumps are more suited to high flow situations, while others are able to precisely control low flows.

- Pressure requirements: Ensure that the pump is able to withstand the required operating pressure.

- The nature of the liquid: consider the characteristics of the liquid (e.g. whether it contains solids, whether it is sensitive, etc.) and select the appropriate pump.

Summary

Viscous liquid pumps are key to efficient liquid transfer, especially when dealing with thick, viscous liquids. Choosing the right pump not only improves operational efficiency, but also extends the life of your equipment. Whether you are handling sludge, oil or syrup, understanding the different types of pumps and their applications is essential to optimizing the process.

At AOBL, we offer a wide range of pumps, including EODD pumps, chemical pumps, sanitary diaphragm pumps, and a variety of pump accessories designed to meet the needs of handling viscous liquids. Contact us today to find the perfect solution for your application.