Shear Stress VS Shear Rate in Fuild Mechanics

Definition Of Shear Stress

What is shear stress?

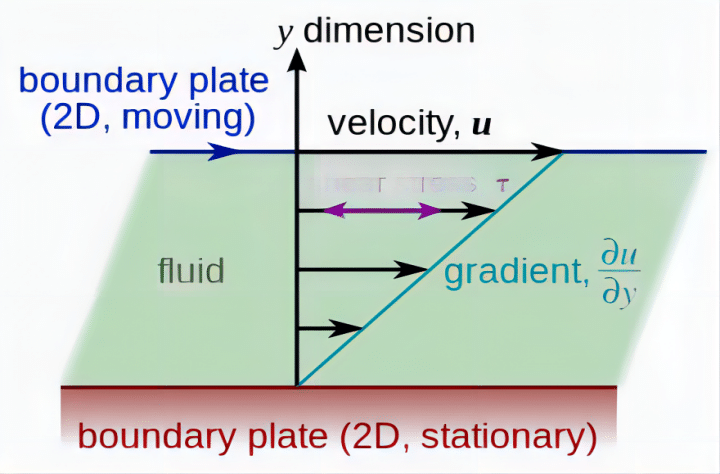

A shear stress is a tangential force perpendicular to the surface of an object that attempts to move different parts of the interior of the object relative to each other along a plane. Shear stresses exist between two neighboring object surfaces when they move relative to each other in the direction of each other. This type of stress can cause objects to deform, such as twisting or sliding, especially in solids or liquids.

Shear Stress In Fluids

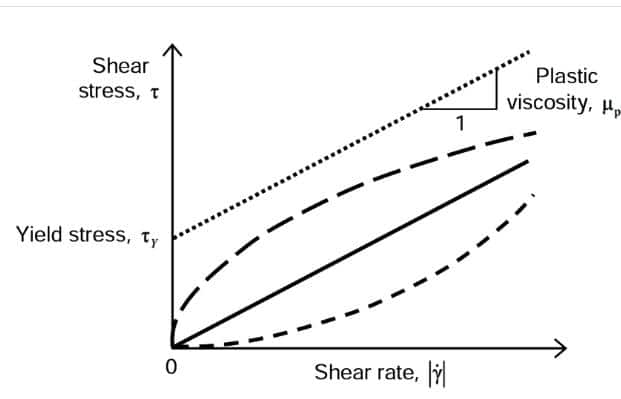

Shear stresses were also observed in the fluid. When a fluid flows within a solid boundary, shear stresses are observed along the point of contact between the fluid and the boundary. The fluid consists of different levels, each moving at a different velocity. Layers at the same height from the boundary experience the same velocity. The change in velocity between the layers is also a result of shear stress. In fluids, the relationship between stress and strain is different. Here, the shear stress is proportional to the strain rate and the viscosity acts as a constant of proportionality.

In fluids, shear stress describes the internal stress between different layers within the fluid due to relative motion. This shear stress is related to the flow properties of the fluid and it can be described by the shear rate of the fluid.

Definition of shear rate

Shear rate is the rate of relative motion between different layers within a fluid or solid. Shear rate occurs when relative motion occurs between different layers within an object. This rate of motion describes the degree of relative movement between neighboring layers.

In fluid mechanics, the shear rate describes the difference in relative velocity between neighboring layers within a fluid. For example, in a fluid where there is relative motion between different layers due to viscosity, the bottom layer of fluid may have a different velocity than the top layer of fluid.

Difference Between Shear Stress And Shear Rate

Shear stress and shear rate are interrelated in that shear stress acts on the interior of a substance, while shear rate describes the rate of relative motion resulting from this stress. In fluid mechanics and solid mechanics, these two concepts are often used together to describe the motion and deformation within a substance.

Impact of Shear Rate on Pump Performance

- Viscosity effects: Shear rate can have an effect on the viscosity of a liquid. Higher shear rates may cause the fluid to shear thinner, while lower shear rates may cause the fluid to become more viscous. This may have an effect on some industrial processes where the viscosity needs to be kept constant.

- Liquid property changes: High shear rates may affect some of the physical properties in the liquid, such as solubility, dispersion, and emulsification. This may be a change for some applications that need to deal with special liquid properties.

- Pump efficiency: Within the pump, high shear rates may cause energy loss in the liquid, resulting in a reduction in pump efficiency. In addition, high shear rates may increase pump wear and heat generation, affecting pump life and stability.

- Pump flow and pressure: For some liquids, especially those susceptible to shear (e.g., polymers, biomaterials, etc.), changes in shear rate may directly affect pump flow and output pressure.

How to choose a pump?

Different types of pumps are suitable for different shear stress and shear rate conditions. This depends on the characteristics of the fluid and the fluid application to be handled.

Pumps For Low Shear Stress And Rate Pumps

Peristaltic pump: This type of pump conveys fluid by gently squeezing a hose, which exerts a low shear force on the fluid. Suitable for shear-sensitive fluids such as biological samples, pharmaceuticals, foodstuffs, etc.

Reciprocating pump: Reciprocating pump convey liquids by increasing and decreasing the volume and have less shear on the liquid. Among them, progressive cavity pumps and piston pumps are common types.

Eccentric screw pumps are closed positive displacement pumps with excellent media adaptability, stable flow output, and superior suction performance. It is suitable for almost all industrial scenarios and can effectively transport media from low to high viscosity.

Eccentric screw pumps are closed positive displacement pumps with excellent media adaptability, stable flow output, and superior suction performance. It is suitable for almost all industrial scenarios and can effectively transport media from low to high viscosity.

Pumps For High Shear Stress And Rates

Centrifugal pumps: Also known as horizontal pumps, these pumps generate centrifugal force by rotating at high speeds and are suitable for applications where high flow rates and pressures are required and where shear is less of a concern, e.g. water treatment in chemical processes, water supply systems, etc.

Shear pumps: Specially designed to handle fluids that are sensitive to shear rates. They are specially designed to reduce shear and are suitable for applications where the characteristics of the fluid need to be maintained, such as emulsification, mixing, stirring, etc.

Summary

These two concepts play an important role in describing the relationship between relative motion and forces within matter and are important for understanding the behavior and properties of fluids and solid materials.

AOBL has a team of professionals dedicated to the field of air operated diaphragm pumps and other fluid transfer pumps, offering a wide range of products including AODD diaphragm pumps, sanitary diaphragm pump, magnetic drive pump and pulsation dampener. Feel free to contact our team of professional engineers for equipment quotes or consulting solutions.