Pump Stators

What is a pump stator?

A pump stator is an important component of certain types of pumps that is typically used to interact with moving parts (e.g., rotors, screws, etc.) to pump a liquid. The stator is usually immobile, while the rest of the pump moves under the action of the stator to propel the liquid.

It is also a type of positive displacement pump and they can be used to pump a wide range of viscous and abrasive fluids.

Pump stator material selection

The stator material is usually a rubber type elastic material. The correct one can be selected depending on the pump application. In some special cases, they can also be made of plastic, PTFE or metal.

- NR (natural rubber)

- NBR (Nitrile Butadiene Rubber)

- HNBR (Hydrogenated Nitrile Rubber)

- EPDM

- FKM (Fluorine rubber, e.g. Viton)

- PTFE (Teflon)

How do pump stators work?

The stator is an immovable part of the pump and its operation depends on the type of pump.

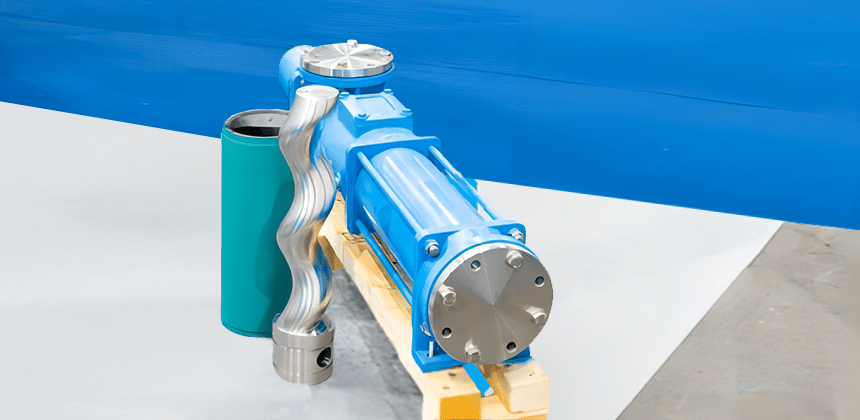

Progressive Cavity Pump

- The stator of a progressive cavity pump is the immovable part of the pump chamber and is usually a tubular structure.

- The internal surface of the stator usually matches the contour of the screw to ensure a tight seal.

- progressive cavity pumps work by a screw rotating inside the stator, pumping liquid from the inlet and pushing it to the outlet.

- As the progressive cavity rotates, the threaded shape of the cavity gradually pushes the liquid forward while maintaining a tight seal in the pump chamber.

Peristaltic Pump

- The stator of a peristaltic pump is a soft tube inside the pump head, usually made of rubber or silicone.

- There are one or more squeezers or compressors in the pump head that clamp down on the soft tubing.

- The way the pump works is that the extruder or compressor squeezes the flexible tubing in a specific peristaltic pattern, which pushes the fluid forward.

- This process of squeezing and releasing mimics the peristaltic movement of the human intestines, hence the name “peristaltic pump”.

Centrifugal Pump

- The stator of a centrifugal pump usually refers to the static part of the pump, including the pump casing and stator vanes.

- The core part of the pump is the rotating impeller (rotor), which generates centrifugal force by rotating.

- The centrifugal force pumps the liquid into the pump casing and outward, and the shape of the stator vanes helps direct the liquid to the outlet.

- The main function of the stator is to maintain the flow path of the liquid and ensure that the liquid remains sealed inside the pump.

Pump stators play a key role in the workings of all three of these types of pumps, helping to achieve pumping and sealing of liquids. Each pump type has a different stator design and function to meet the requirements of different applications. The stator’s job is to work in tandem with the other components of the pump to achieve the pump’s main goal: to move liquids from one place to another.

What is the purpose of a stator pump?

Stator pumps usually refer to a key component in screw pumps or certain centrifugal pumps where the stator serves different purposes.

Progressive cavity pumps: In a progressive cavity pump, the stator is an immovable part of the pump chamber, usually a tubular structure made of metal or other corrosion-resistant material. The stator is one of the key pumping components of a progressive cavity pump. It is also known as the PC (Progressive Cavity) pump cylinder liner.The PC pump stator usually consists of a casing and a cylinder liner. The uses of progressive cavity pumps include:

- Liquid transfer: Progressive cavity pumps are primarily used to transfer a variety of liquids, including highly viscous, high temperature or corrosive liquids. They are typically used in industrial applications such as chemical, petroleum and food production to pump liquids from one place to another.

- Precise flow control: Because of their ability to provide relatively precise flow control, progressive cavity pumps can also be used in applications that require precise metering, such as processing and mixing.

Eccentric screw pumps are internal mesh, closed positive displacement pumps that can be used in virtually all industrial applications for pumping low viscosity to viscous media due to the pump’s adaptability to the medium, smooth flow, and good suction performance.

Centrifugal pumps: In centrifugal pumps, stator usually refers to the static part of the pump, including the pump casing and stator vanes. Uses of centrifugal pumps include liquid pumping. Centrifugal pumps are one of the most common types of pumps used to pump a variety of liquids such as water, chemicals, oil, sewage, and more. They are widely used in construction, agriculture, industry and municipal facilities.

What are the relevant factors to consider when selecting a pump stator?

The size and diameter of the material, the particles and the flow rate you want to achieve.

You need to select a rotor stator based on the size and diameter of the rotor stator, the particle size of the material and the desired flow rate. Different rotor stator pumps are suitable for different materials and applications and achieve different pumping results. Different flow rates and pressure stability can be achieved with different pump designs.

Pump Stator Damage Factors

| Causes | Description And Impact |

| Accumulation of substances and pollution | Solid particles, deposits, or contaminants build up on the stator surface, causing increased friction and damage to the stator surface. This may reduce pump performance and efficiency. |

| Corrosion and chemical corrosion | Pumps operating in corrosive liquids may cause stator surface corrosion. This may weaken the structural strength of the stator and shorten its service life. |

| High temperature and thermal stress | High temperature operation may cause deformation or damage to the stator material. Prolonged exposure to high temperatures may reduce the strength and durability of the stator. |

| Foreign matter entering the pump system | Foreign materials such as grit, debris, metal flakes, etc. entering the pump system may get stuck in the stator gap or cause mechanical shock and damage the stator surface. |

| Coupling and seal failure | If the pump coupling or seals fail, this may result in erratic stator operation or additional stress and friction, increasing the risk of damage. |

How can I prevent the pump stator from spinning dry?

Preventing the pump stator from spinning dry is one of the key steps in ensuring proper operation of your pump system and extending the life of your pump. Pump stators rotating without adequate lubrication or fluid can cause damage.

- Level Monitor: Install a level monitor or sensor to monitor the level of liquid at the pump inlet or around the pump. When the level drops to a preset warning level, the monitor can sound an alarm or stop the pump to prevent dry running.

- Flow control: If the flow rate falls below a preset threshold, the flow controller can automatically shut down the pump or trigger an alarm.

- Pressure sensor: A pressure sensor is installed to monitor the pump’s outlet pressure. If the pressure is outside the normal range or drops to a dangerous level, the sensor can trigger a stop to the pump operation.

- Timers and control systems: Use timers and automatic control systems to ensure that the pump runs when needed and stops when there is not enough fluid.

- Fluid supply systems: This can be achieved by installing additional storage containers, using submerged pumps, or taking other measures to supply fluid.

Summary

Pump stators are critical to pump efficiency within a pump, and how you choose one is crucial. Pump stators are usually made from a variety of rubbers or plastics, their shape forms the shape of the pump rotor, they work together to ensure that fluid movement is always forward, these parts act as internal valves within the pump preventing the fluid from returning to the inlet (positive displacement).

As experts in air operated diaphragm pumps and other fluid transfer pumps, AOBL provides best-in-class pumping and engineering innovations to meet the toughest and most demanding pumping challenges. We offer a wide range of AODD pumps and fluid handling products and solutions, providing EODD pumps, double diaphragm pumps, sanitary diaphragm pumps, filter press feed pumps, parts and accessories to ensure your success, feel free to contact us.