Magnetic Coupling for Pumps

Magnetic coupling technology is an important innovation in modern engineering that prevents corrosive, toxic or flammable liquids from leaking into the atmosphere, and excels in scenarios where there is a need to reduce the risk of leakage and improve equipment safety.

Definition Of Magnetic Coupling

What is a magnetic coupling?

Magnetic coupling is a technology that connects two rotating parts using a magnetic field rather than a mechanical connection to transmit power and rotational motion. This technique is typically used in application scenarios where isolation between drive components is required, such as where leakage prevention or friction reduction is desired.

Structural Components Of Magnetic Coupling

External driven part: Contains a rotating permanent magnet or electromagnetic coil that generates a magnetic field for transmitting power.

Internal driven part: Connected to the external part and receives the power transmitted by the magnetic field. Usually contains another permanent magnet or solenoid that corresponds to the magnetic field of the external driven part.

Magnetic Coupling Application Scenarios

- Pumping Equipment: In pump applications, the magnetic coupling can be used to isolate the driving and driven portions of the pump, avoiding mechanical bearings and direct contact, helping to prevent leaks, and improving equipment reliability.

- Stirrers and Mixers: In stirrers or mixers for mixing liquids, magnetic coupling allows for rotary motion without the need for mechanical bearings and penetration of vessel walls.

- High-Pressure Environments: In some high-pressure or high-temperature environments, magnetic coupling can provide a more reliable solution that reduces the challenges faced by traditional seals.

Working Principle of Magnetic Coupling

Magnetic coupling utilizes the interaction created by a magnetic field to cause the internal driven part to follow the motion of the external driven part. This contactless drive allows torque and rotary motion to be transmitted in different physical spaces.

Type Of Magnetic Coupling

Magnetic couplers can usually be categorized into the following types:

1. External magnetic couplers:

External Magnetic Couplers make connections and drives by transferring a magnetic field to isolated components used to protect internal mechanical components from the external environment. This design allows the internal equipment to be operated and driven from the outside while keeping the equipment enclosed.

2. Internal magnetic coupler:

Internal Magnetic Couplings are designed to be used as a connection between internal components, usually for the transfer of magnetic force without the need for an actual physical connection between environments. This type of magnetic coupling is commonly found in closed systems or in applications where friction needs to be avoided internally.

3. Magnetic coupling drive system:

Magnetic Coupling Drive Systems utilize magnetic forces to transmit torque from the outside to the inside for driving rotors, impellers, or other rotating equipment. This system avoids physical connections and provides better sealing and operational safety in some applications.

4. Hybrid magnetic coupler:

A Hybrid Magnetic Coupler combines different types of magnetic coupling technology to suit specific application requirements. It can combine the characteristics of both external and internal magnetic couplings to provide a more flexible and reliable drive train.

These magnetic coupler types have their own characteristics and application areas, and the appropriate magnetic coupler type can be selected based on different engineering requirements and operating environments.

Advantages of Magnetic Coupling

- Leak prevention

- Reduced maintenance costs

- High level of safety

- Elimination of mechanical contact:

- Isolation performance

- Wide applicability

- Flexibility

Difference Between Magnetic and Inductive Couplers

Magnetic couplers are used for transmitting torque or rotational force, which transmits power through a magnetic field, while inductive couplers utilize electromagnetic induction to transmit energy or information, and are used in wireless charging, non-contact sensors, and other areas. Due to the principle of electromagnetic induction, they are suitable for scenarios that require wireless transmission of energy or information.

Pumps for Magnetic Coupling

Magnetic couplers are commonly used in pumping equipment where there is a need to prevent leakage or avoid traditional mechanical contact. Below are some common pump types that are suitable for the use of magnetic couplers:

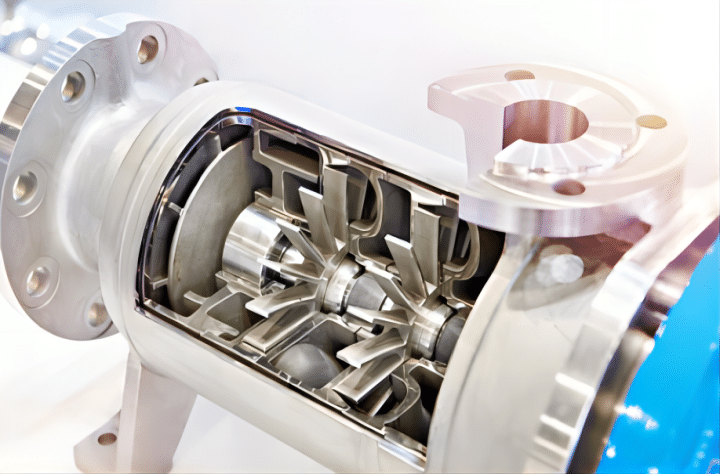

1. Centrifugal pumps:

Centrifugal pumps are typically used for liquid transfer and are designed to be suitable for magnetic coupler applications. By using a magnetic coupler, traditional mechanical seals can be avoided, reducing the risk of leakage from the pump, especially when corrosive or hazardous liquids need to be handled. AOBL vertical corrosion resistant chemical pumps are used for transferring acids, alkalis, highly corrosive chemicals and general hazardous liquids. There are various types as well as a wide range of advanced chemical resistant materials.

2. Agitator pumps:

Agitator pumps for mixing liquids or suspending particles are also potential applications for magnetic couplers. These types of pumps are often used in environments where leakage prevention or frictionless drives are required, and magnetic couplings can provide a more reliable solution.

3. Magnetic drive pumps:

Magnetic drive pumps commonly used in applications where leakage prevention is required or where a high degree of safety is required. These pumps are characterized by the fact that there is no mechanical contact between the driving and driven parts, but rather power is transmitted through a magnetic field.

4. piston pumps:

Reciprocating pumps are pumps that transfer liquid through a reciprocating motion, and some designs allow the use of magnetic couplings. In some high-pressure environments, magnetic couplings can provide a more reliable sealing solution.

5. Progressive Cavity Pump:

Progressive cavity pump are pumps that transfer liquids through a helical structure. Certain designs can also utilize magnetic couplers, especially where there is a need to avoid liquid leakage or reduce maintenance costs. Eccentric screw pumps produce volume changes in the suction and discharge chambers to transfer liquids.

The application of magnetic couplers in these pumps is usually done to improve system safety, reduce maintenance costs, avoid liquid leakage, and minimize problems associated with conventional mechanical seals. However, when selecting a magnetic coupler, factors such as fluid properties, pressure, temperature, and operating environment need to be considered to ensure its suitability.

Summary

Magnetic coupling technology is widely used in modern engineering, especially in equipment that requires leak-proofing and increased safety. While presenting certain cost and design challenges, the reliability and safety they provide make them highly desirable in a wide range of industrial applications.

AOBL specializes in water treatment, and our product line covers a wide range of pump types, including air-operated diaphragm pumps, chemical pumps, as well as filter press feed pumps, and pump accessories. We have an experienced technical team, please feel free to contact us.