Pseudoplastic Fluid

What is pseudoplastic fluid?

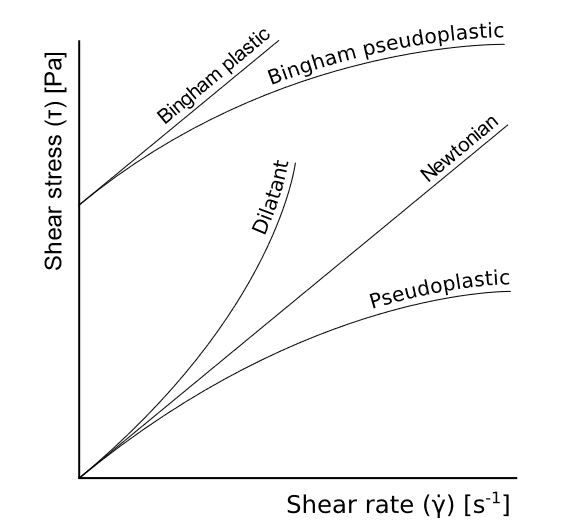

A pseudoplastic fluid is a non-Newtonian fluid whose viscosity decreases with increasing shear rate. This property causes pseudoplastic fluids to exhibit lower viscosity at higher shear rates and higher viscosity at lower shear rates.

Pseudoplastic fluids are common in practical applications, especially in the food, chemical, and medical fields, as well as in some industrial and scientific experiments. For these fields, understanding and mastering the properties of pseudoplastic fluids is essential for product design and engineering applications.

Examples of Pseudoplastic Fluid Applications

Toothpaste: Toothpaste is a common example of a pseudoplastic fluid. It exhibits high viscosity (low shear rate) when extruded. Still, when brushed, the viscosity of the toothpaste decreases and flows more easily due to the shear force exerted by the movement of the toothbrush.

Certain lubricants: Certain lubricants will exhibit pseudoplastic properties when mechanical equipment is in operation. The viscosity of the lubricant is higher when the mechanical parts are moving at lower speeds, but decreases when the speed increases to better lubricate the mechanical parts.

Biological fluids: Biological fluids like blood and joint fluids also exhibit pseudoplastic properties. They are more viscous at rest, but their viscosity decreases and flows more easily when the body part is moving.

Pseudoplastic Fluids At Shear Rates

The behavior of pseudoplastic fluids at shear rates is mainly characterized by changes in their viscosity. In general, the viscosity of pseudoplastic fluids decreases as the shear rate increases.

- At low shear rates: pseudoplastic fluids exhibit high viscosity, similar to the properties of solids. At lower shear rates, the fluid molecules interact more strongly with each other, resulting in a fluid that exhibits relatively high viscosity and stickiness.

- At high shear rates: As the shear rate increases, the viscosity of the pseudoplastic fluid decreases and the fluid molecules are rearranged by the shear force. At higher shear rates, the interaction between fluid molecules decreases, resulting in the fluid exhibiting lower viscosity and better flow.

This effect of shear rate on viscosity is a unique property of pseudoplastic fluids and an important characteristic of non-Newtonian fluids. This property is important for many industrial applications and experiments because it allows the behavior and flow properties of the fluid to be controlled under different shear conditions.

Differences Between Pseudoplastic, Nonviscous, And Plastic Fluids

The properties of pseudoplastic, nonviscous, and plastic fluids are compared, showing how they behave differently in terms of rheological properties, shear rate effects, and viscosity changes.

| Characterization | Pseudoplastic Fluids | Non-Viscous Fluid | Plastic Fluid |

| Rheological Properties | Viscosity decreases with increasing shear rate | Does not vary with shear rate | Need to exceed yield stress to start flowing |

| Shear rate effects | Flow properties increase with increasing shear rate | Not affected by shear rate | Need to exceed the yield point to start flowing |

| Viscosity Change | Higher viscosity at low shear rates, lower viscosity at higher rates | No significant viscosity change | Cannot flow below yield stress, will flow above yield stress |

| Example | Toothpaste, some lubricants, some biological fluids | Gases, some liquids | Slurries, some colloids, some paints |

Pumps For Pseudoplastic Fluids

Pseudoplastic fluids exhibit different viscosity characteristics at different shear rates, so pumps suitable for handling this type of fluid need to take their rheological properties into account. The following are some common pump types suitable for pseudoplastic fluids:

Centrifugal pumps: A type of process pump, centrifugal pumps may be a suitable choice for certain pseudoplastic fluids. They perform well with certain non-newtonian fluids. As the shear rate of the fluid increases, centrifugal pumps can provide the required flow rate and pressure because pseudoplastic fluids exhibit lower viscosity at high shear rates. AOBL vertical centrifugal pump is a good choice.

Progressive cavity pumps: Progressive cavity pumps are also suitable for pseudoplastic fluids because they can effectively handle fluids with higher viscosities. The construction of progressive cavity pumps allows them to effectively cope with pseudoplastic fluids at different shear rates.

Piston pumps: Piston pumps are well adapted to handle pseudoplastic fluids and are able to provide consistent flow rates and pressures under varying flow conditions.

Diaphragm pumps: Diaphragm pumps can effectively handle not only pseudoplastic fluids, but also transport some corrosive fluids; as they are designed to accommodate changes in fluid viscosity and rheological properties. The diaphragm pumps of the KES 25 can be adapted to most fluid transfer treatments.

Summary

Pseudoplastic fluids behave differently at different shear rates. These fluids exhibit different viscosity characteristics under different shear conditions and, unlike plastic fluids, pseudoplastic fluids do not have a defined yield point or threshold. Pumps suitable for handling this type of fluid need to consider its rheological properties.

AOBL specializes in the water treatment industry, they offer a wide range of pumps for different purposes, used in conjunction with pulsation dampers and filters, to optimize the industrial processes of water treatment, contact us for professional technical support!