Reciprocating Pump VS Centrifugal Pump

When it comes to fluid transportation, choosing the right pump is crucial for efficiency and reliability. Among the various types of pumps available, reciprocating and centrifugal pumps stand out as two of the most commonly used in industrial and commercial applications. Both types have unique advantages, working principles, and ideal use cases. Understanding the differences between reciprocating pumps and centrifugal pumps can help you decide on your specific needs.

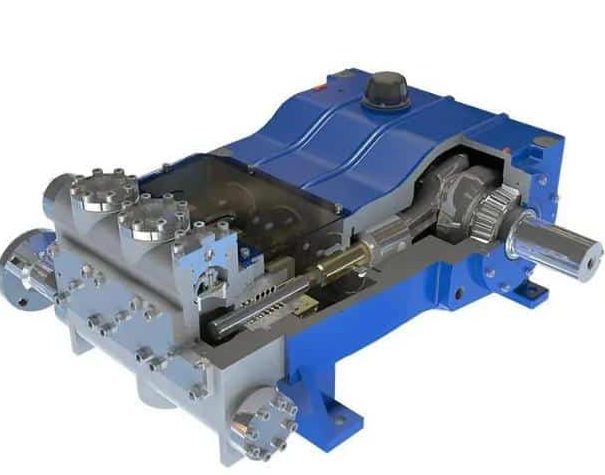

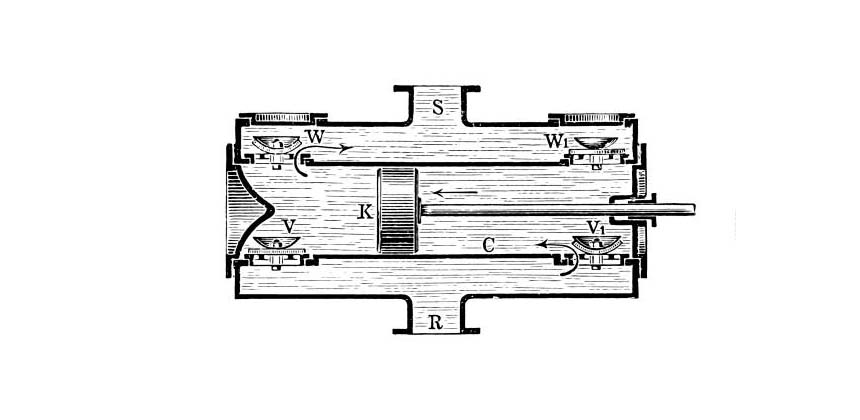

What is a reciprocating pump?

The reciprocating pump is a kind of pump that conveys fluid through reciprocating motion, which belongs to a positive displacement pump. It uses the piston or plunger in the pump cylinder reciprocating motion, so that the piston or plunger and the pump cylinder wall of the volume formed between the change, to inhale and exclude the liquid and increase its pressure.

Principle of Operation:

Suction Process

- The piston, plunger, or diaphragm moves backward and the volume in the pump chamber increases, creating low pressure.

- The suction valve opens and fluid is sucked into the pump chamber.

Discharge Process

1. The piston, plunger or diaphragm moves forward, the volume in the pump chamber decreases and the pressure rises.

2. The suction valve closes, the discharge valve opens, and the fluid is discharged from the pump chamber.

Features

- High efficiency

- High pressure capability

- Good controllability

- Self-priming capability

- Wide choice of materials

Advantages of Reciprocating Pumps

- Simple structure, intuitive working principle, easy maintenance;

- A wide range of applications, can convey various liquids, including viscous liquids, corrosive liquids, and liquids containing solid particles;

- Can generate high pressure, suitable for occasions requiring high pressure liquids.

Applications

- Chemical and petroleum industry

- Pharmaceutical and food industry

- Water treatment and environmental protection

- Other industries

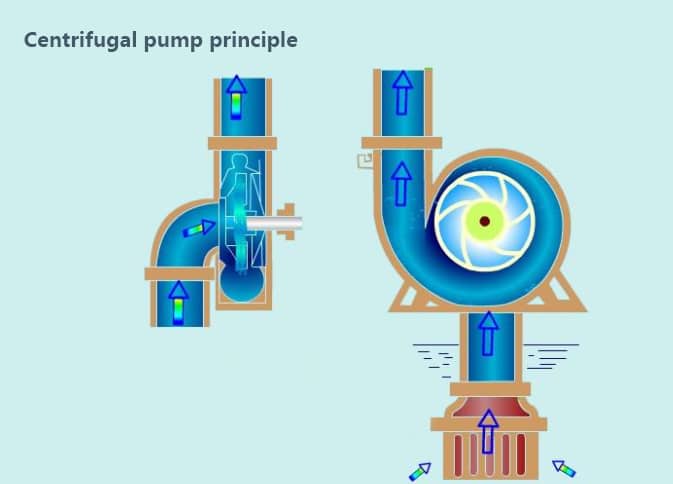

What is a centrifugal pump?

A centrifugal pump is a common fluid mechanical device that conveys fluid from a low-pressure area to a high-pressure area through the action of centrifugal force. It utilizes the kinetic energy generated by the rotating impeller on the fluid to convert the mechanical energy into the kinetic and potential energy of the fluid to achieve the transportation of the fluid.

Principle of Operation

Suction process

- When the pump starts, the impeller rotates to generate centrifugal force, which forms a low-pressure area in the pump cavity.

- The external fluid enters the pump chamber through the suction pipe under the action of atmospheric pressure or other pressure sources.

Acceleration Process

- After the fluid enters the impeller, it is grasped by the vanes of the impeller and rotates with the impeller, and the fluid moves to the outer edge along the vane channel under the action of centrifugal force.

- In this process, the velocity of the fluid increases, and the kinetic energy increases.

Discharge process: - When the fluid reaches the outer edge of the impeller, its speed and kinetic energy reach the maximum value.

- The fluid is guided to the discharge pipe through the pump casing (worm casing), during which the kinetic energy is partially converted into pressure energy, forming a high-pressure fluid and completing the fluid transportation.

Applications

- Municipal engineering.

- Industrial processes

- Agriculture

- Air conditioning, heating systems, fire protection systems.

- Sewage treatment and water purification.

Advantages of Centrifugal Pumps

- Simple structure, easy to manufacture and maintain.

- Smooth operation, uniform flow, suitable for continuous operation.

- High efficiency, good energy conversion efficiency.

- It can convey liquids of different viscosity and nature, including corrosive liquids and liquids containing particles.

- Conveniently adjust the head by adjusting the pump speed and outlet valve.

Difference Between The Two Pumps

Flow and Pressure Characteristics

Capacity

- Reciprocating pump is a volumetric pump, its displacement is proportional to the stroke and cross-sectional area of the piston or plunger and proportional to the rotational speed, the capacity can be constant or adjustable.

- Centrifugal pumps are dynamic pumps whose displacement is directly proportional to the diameter of the impeller, the rotational speed and the density of the liquid, so the capacity of centrifugal pumps usually varies with the rotational speed.

Lift

- Reciprocating pumps can generate high pressures and their heads can reach hundreds or even thousands of meters.

- Centrifugal pumps have a narrower range of heads, generally between tens and hundreds of meters.

Efficiency

- Reciprocating pumps have a theoretical efficiency of 100%, but actual efficiencies are generally between 70% and 90%.

- Centrifugal pumps generally have efficiencies between 60% and 80%.

Effect of Viscosity

- Reciprocating pumps have less effect on the viscosity of the liquid and can convey liquids of various viscosities.

- Centrifugal pumps are sensitive to the viscosity of the liquid, and the higher the viscosity of the liquid, the lower the efficiency of the centrifugal pump.

Applicable Fluid Type

Reciprocating pumps: Suitable for conveying high-viscosity, particle-containing or corrosive fluids, capable of handling a wide range of liquids with different properties.

Centrifugal pumping: Suitable for conveying clear water, sewage, and low viscosity liquids, not suitable for high-viscosity or solid particle-containing fluids.

Summary

Choosing the right pump for your application needs is no easy task, and reciprocating and centrifugal pumps each have their own unique advantages and limitations. Hopefully, the comparison provided in this article will help you better understand the differences between these two pumps and make the best choice for your specific operational needs. Whether you need consistent flow or efficient transfer performance, the right choice can greatly enhance your system’s efficiency and reliability.

AOBL is unique in the field of pump manufacturing with its excellent technology and quality service, providing air-operated diaphragm pumps, chemical pumps, EODD pumps, sanitary diaphragm pumps, filter press feed pumps, as well as pump accessories and pulsation dampers. We believe that with AOBL support, you will be able to find the most suitable solution for your needs, and greatly improve the efficiency and reliability of your system.