Shaft Coupling For Pump

What is a shaft coupling?

A shaft coupling is a mechanical device used to connect two shafts or components of a shaft to a rotating mechanical device. Its primary function is to connect two shafts so that they can rotate together and transmit power or rotary motion. Often designed as a detachable joint, they can be used to connect different mechanical devices or to transfer power from one device to another. They allow for some degree of misalignment or offset of the two shafts relative to each other while being able to maintain the transfer of rotation between the shafts.

Shaft Coupling For Pump Applications

Shaft couplings play an important role in pump application scenarios and are primarily used to connect the pump drive (e.g. motor, engine) to the shaft of the pump itself. This device allows for the transmission of rotary motion and power, and allows for a degree of misalignment or offset between the shafts, thus ensuring that the pump can function properly.

- Connecting the Motor to the Pump Shaft: In many pump systems, the motor is connected to the pump shaft by a shaft coupling. This connection allows the rotational force of the motor to be transmitted to the pump, allowing the pump to perform its normal pumping or fluid transfer duties.

- Alignment and Adjustment: Couplings allow the axis between the motor and pump shafts to be aligned and adjusted to suit different installation conditions and pump systems. They can compensate for shaft misalignment to some extent, reducing vibration and losses due to misalignment.

- Protection of equipment: coupling in the pump system also has a protective role, when the system appears abnormal load or torque is too large, the coupling can play a buffer and protection to prevent damage to the equipment.

- Maintenance and Replacement: During pump maintenance and replacement, the design of the coupling makes it relatively easy to remove and replace components such as the pump or motor, reducing the complexity of the repair and replacement process.

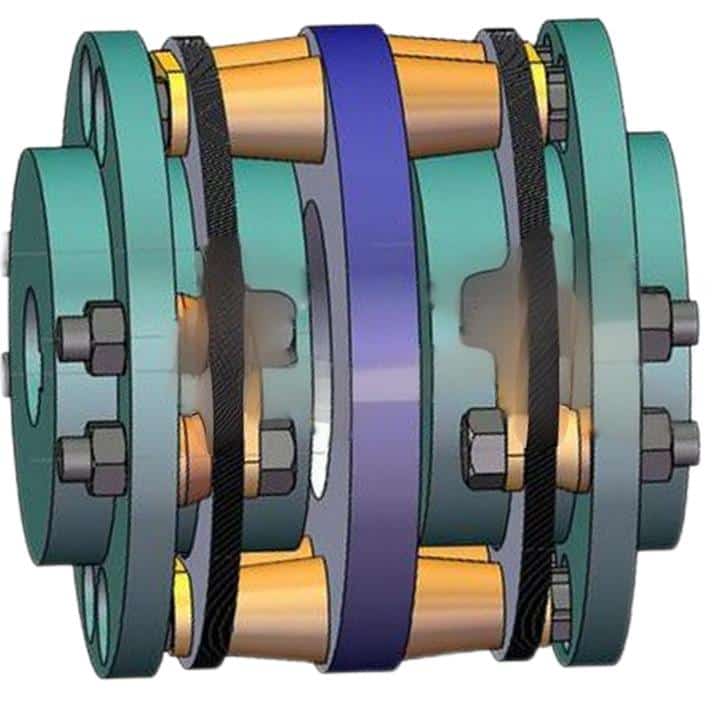

Types Of Shaft Couplings For Pumps

- Flexible couplings: This type of coupling is suitable for pump systems where vibration and shock need to be minimized. They can compensate for some shaft deflections and misalignments while protecting the equipment from sudden loads and vibrations.

- Toothed couplings: Toothed couplings are typically used in higher-power pumping systems and are capable of transmitting higher torque with greater durability and stability.

- Helical tooth couplings: These types of couplings are used in pump systems that require high torque transmission with high accuracy and stability, and are often used in demanding applications.

- Jacketed couplings: Jacketed couplings are commonly used in pump systems that require quick installation and removal for ease of maintenance and replacement.

- Universal joint couplings: Universal joint couplings allow torque to be transmitted in multiple axial directions and are suitable for pump systems with some axial offset.

- Metallic flexible couplings: These couplings are used in pump systems that require high torque transfer and large angular deflections while providing good durability and stability.

Differences Between Shaft Coupling And Magnetic Coupling

The terms “shaft coupling” and “magnetic coupler” are sometimes used in engineering to denote similar concepts, but there are some differences. Shaft couplings can be thought of as a subcategory of couplers, specific types of connectors used to connect and transfer power or torque. The term coupler, on the other hand, is broader and can be used to describe many different types of connecting devices or connecting components.

Pumps Suitable For Shaft Coupling

- Centrifugal Pumps: Generally horizontal pumps. Centrifugal pumps are typically used for transferring liquids and can be connected to the motor and pump to ensure efficient power transfer to drive the centrifugal pump. AOBL vertical chemical pumps can be used for a variety of industrial pumping applications.

- Plunger pumps: Plunger pumps are used for high-pressure applications, and shaft couplings ensure the connection between the drive unit (e.g., engine or electric motor) and the plunger pump.

- Screw pumps: Screw pumps are used for conveying highly viscous liquids or volatile media, and are suitable for connecting pumps and power sources with shaft couplings.

- Mixed-flow and axial-flow pumps: These pumps are used for water treatment or agricultural irrigation and can be used to connect pumps and drive equipment.

- Diaphragm pumps: Diaphragm pumps are used to convey toxic or volatile liquids, and shaft couplings can ensure the connection between the pump and the drive equipment and transfer power. AOBL air-operated diaphragm pumps are capable of conveying a wide range of different liquids, including corrosive liquids.

These pumps are widely used in different industries and applications, and the shaft coupling is a key component in ensuring an effective connection between the pump and the driving equipment (e.g., motor, engine).

How to maintain the shaft coupling?

- Regular inspection and lubrication

- Maintain cleanliness

- Align and adjust

- Replace worn parts

- Avoid overloading

Summary

Shaft couplings play an important role in the engineering field, ensuring the proper operation of mechanical equipment and reducing damage and failures due to axial misalignment, vibration, or overload. Proper selection and maintenance of shaft couplings is essential for the long-term stable operation of equipment.

AOBL is an expert in the field of water treatment, they offer a wide range of pumps, from EODD pumps to sanitary diaphragm pumps, chemical pumps, and pulsation dampers. Contact us, you can not only get high-quality and reliable products but also get professional and thoughtful technical support and perfect after-sales service.