Types Of Pumps

Pumps are indispensable equipment in the process of fluid transportation and treatment, and are widely used in various fields such as industry, agriculture, construction and household. According to different working principles and application requirements, there are various types of pumps, and each type of pump has its own unique design features and application scenarios.

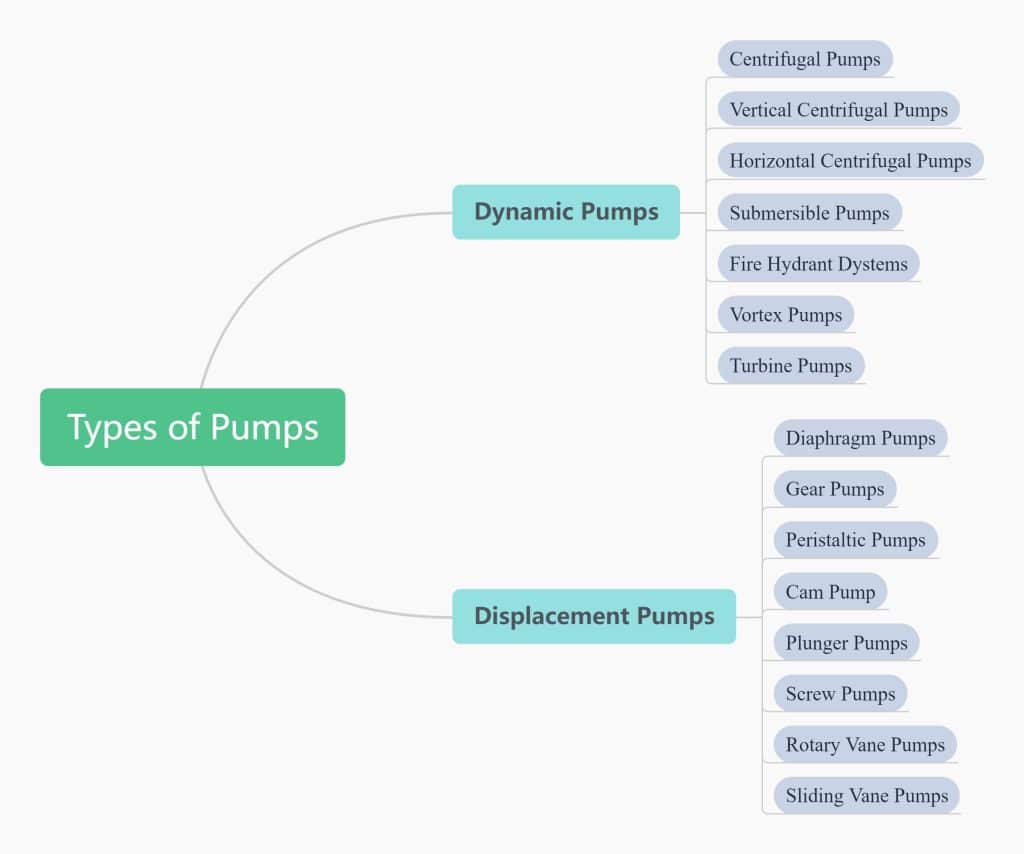

Classification of Pumps

Pumps are divided into two main categories: Centrifugal pumps and displacement pumps (also known as positive displacement pumps).

Dynamic Pumps

Dynamic pumps are pumps that convey fluids by increasing their kinetic energy. They rely on rotating or moving parts (such as impellers or screws) to accelerate the fluid and increase its kinetic energy, which is then converted to pressure energy by diffusers or other stationary parts, thus realizing the conveyance of fluids.

Centrifugal Pumps

Principle: Generate centrifugal force through the impeller rotation, so that the fluid flows along the radial direction, increasing its speed and pressure.

Application: Suitable for various industrial and civil fields, such as water supply and drainage, chemical processes, cooling water circulation, etc.

Centrifugal pumps can be categorized into three subtypes based on the type of water flow produced. The flow pattern is determined by the impeller shape and the pump structure.

| Subtype | Working Principle | Applicable Scenarios | Advantages |

| Axial Pumps | Liquid flows parallel to the pump shaft | Agricultural drainage and irrigation, cooling water circulation | High flow rate and efficiency |

| Radial Flow Pumps | Liquid flow perpendicular to the pump shaft | Municipal water supply, industrial water | High head, simple structure |

| Mixed Flow Pump | Simultaneous axial and radial flow of liquids | Wastewater treatment, irrigation, industrial processes | Moderate flow head and high efficiency |

Vertical Centrifugal Pumps

A vertical centrifugal pump is a kind of centrifugal pump whose pump shaft is arranged vertically, usually used in occasions where space saving or specific installation requirements are needed. It has the advantages of a compact structure, small footprint, and easy installation and maintenance.

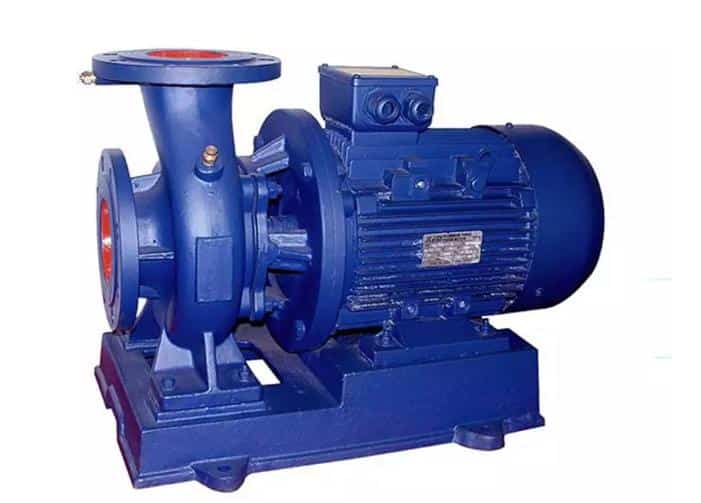

Horizontal Centrifugal Pumps

Horizontal centrifugal pumps include at least two or more impellers. Centrifugal force is generated by the rotation of the impeller, which draws in and accelerates the fluid from the inlet of the pump, converts the kinetic energy into pressure energy by means of a diffuser in the pump casing, and then discharges it from the outlet. They are widely used in a variety of fluid transfer and handling applications.

Submersible Pumps

Submersible pumps are pumps that can be fully immersed in liquids by generating centrifugal force through the rotation of the impeller, which draws in and accelerates the liquid from the inlet of the pump, converts the kinetic energy into pressure energy using a diffuser in the pump casing, and then discharges it from the outlet. It is used for drainage of construction sites, basements, and tunnels, and in sewage treatment for sewage and waste water.

Fire Pumps

Pumps specifically designed to provide high-pressure water flow to support hydrant systems are high-pressure pumps that play a vital role in a building’s fire safety system, ensuring that in the event of a fire sufficient water flow and pressure can be quickly provided to extinguish the fire. Applications lie in irrigation and water supply.

Vortex Pumps

A vortex pump, also known as a scroll pump, is a dynamic type of pump. Its main components are composed of an impeller and a static ring independent of the impeller. When a vortex pump operates, fluid is drawn into the center of the pump and discharged from the impeller by centrifugal force. The design of the vortex pump makes it suitable for handling fluids with strong abrasion resistance properties such as solid particles or high viscosity liquids.

Turbine Pumps

The principle of the turbine pump is similar to the centrifugal pump, but the vane of turbine pump is smaller and rotates at a higher speed, utilizing the high-speed rotating impeller to accelerate the gas molecules, thus reducing the gas pressure, which is accelerated through the high-speed rotating turbine vane, and the liquid is pushed into the pump casing in the radial direction under the action of centrifugal force, thus generating a high-pressure fluid output.

Displacement Pump

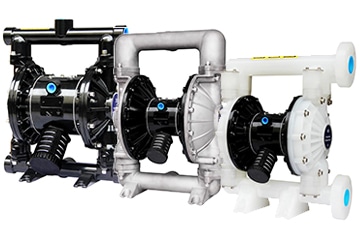

Diaphragm Pumps

A diaphragm pump is a positive displacement pump that propels fluid through a reciprocating flexible diaphragm. Due to its unique working principle and structural design, liquid leakage and contamination are avoided. With significant advantages in handling corrosive liquids, viscous fluids, and volatile liquids, diaphragm pumps are widely used in chemical, pharmaceutical, food processing, environmental protection, and other fields.

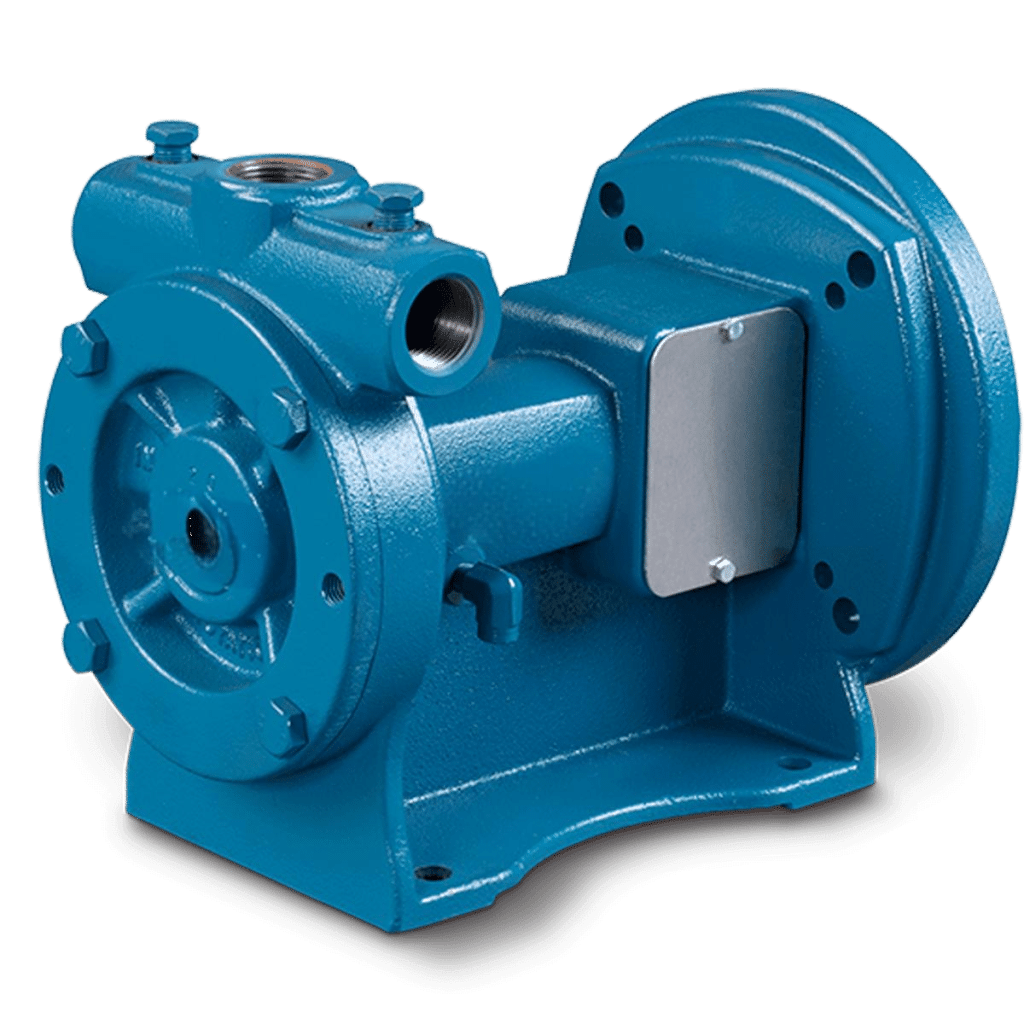

Gear Pumps

Gear pumps are a common type of positive displacement pump that utilizes the meshing of gears to transfer liquids. Gear pumps are widely used in a variety of industrial and commercial applications, and are especially suited for transferring highly viscous liquids such as lubricants, fuel oils, and polymers.

Not suitable for conveying liquids containing large amounts of solid particles, which may get stuck between the gears, affecting the normal operation of the pump and requiring regular maintenance.

Peristaltic Pumps

Peristaltic pumps are positive displacement pumps that push liquid flow by squeezing a flexible hose through a roller. Since the liquid only touches the inner wall of the hose and does not touch other parts of the pump, peristaltic pumps are particularly suitable for transporting liquids that require high cleanliness and no contamination. They are widely used in medical, laboratory, food processing, and chemical industries.

Plunger Pumps

Plunger pumps are highly efficient positive displacement pumps that deliver liquid through the reciprocating motion of a plunger. This reciprocating motion allows the liquid to be delivered in a fixed volume. Due to their ability to generate high pressures and precise flow control, piston pumps are widely used in petroleum, chemical, hydraulic systems and high pressure cleaning.

Lobe Pumps

Also known as rotor pumps, are characterized by high efficiency, rust resistance, good hygienic quality and high reliability. These pumps are capable of handling highly concentrated liquids and solids without damaging them. Compared to gear pumps, cam pumps have superior pumping chambers that move slurry and the vanes do not touch each other. Lobe pumps are usually made of stainless steel and have finely polished surfaces. They can be used in conjunction with gear pumps to provide greater operational performance and flexibility.

Screw Pumps

Screw pump is a kind of positive displacement pump, each screw meshes with each other, screw and liner cylinder wall close fit, between the suction port and discharge port of the pump, it will be separated into one or more sealing space. With the rotation of the screw, these sealing spaces are continuously moved from the suction end to the discharge end, so that the liquid is sucked in from the suction port and pressed to the discharge port. Wide range of application, can convey high viscosity liquid.

Rotary Vane Pumps

Rotary pumps convey liquids by generating volume changes in the pump chamber through a rotating rotor. Rotary pumps are characterized by high efficiency, stability and adaptability, with low shear force on the liquid, and are suitable for the transport of sensitive liquids, including media containing particles and fibers.

Sliding Vane Pumps

A slide pump produces a change in volume by the sliding of a slide on a rotor within a pump casing. The main components include a rotor mounted eccentrically within the pump casing and a plurality of slides. The vanes are located in slots in the rotor and are able to slide freely within the slots. As the rotor rotates, centrifugal force pushes the slide plates against the inner wall of the pump casing, forming multiple sealed working chambers. Thus, liquid transportation is realized. Sliding vane pump has the advantages of simple structure, strong self-priming ability stable flow output, etc. It is suitable for conveying low-viscosity and medium-viscosity liquids, such as fuel oil, solvent, lubricating oil, and so on.

Summary

The versatility of these pumps makes them suitable for a wide range of industrial and commercial applications. Choosing the right pump depends on the nature of the fluid, flow requirements, pressure needs and the specific application scenario.

AOBL Pump Manufacturers possess advanced technology and research and development capabilities, enabling them to produce high-performance, high-efficiency pump products. They offer a range of products including EODD pumps, sanitary diaphragm pumps, filter press feed pumps, and chemical pumps, along with specially designed pump accessories. Contact us to create a customized solution for you!