Types of screw pumps

What is a screw pump?

A screw pump is a positive displacement pump that utilizes the rotary motion of a screw to transfer fluid. Through the rotary motion of one or more screws, they push fluid from one end of the pump to the other. This type of pump is capable of handling highly viscous fluids and fluids containing solid particles. It is widely used in industries such as petroleum, chemical, food, pharmaceutical, and wastewater treatment.

Working Principle of Screw Pumps

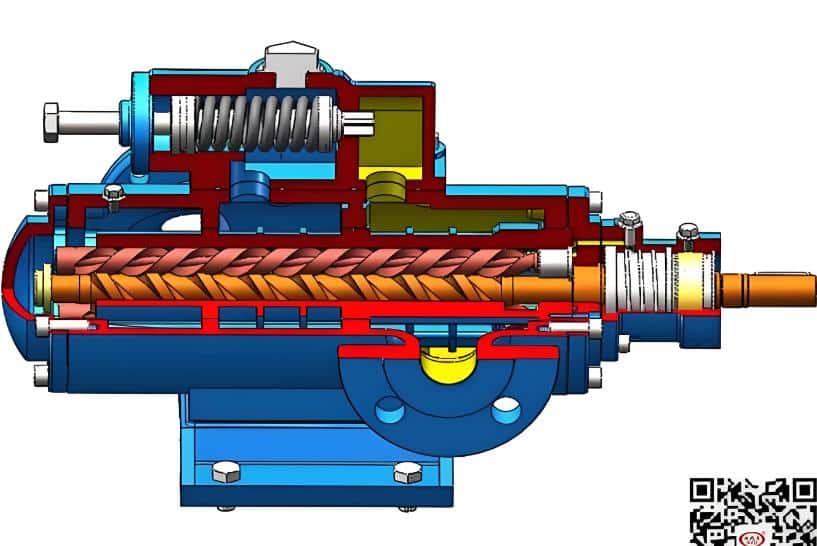

The operating principle of a progressive cavity pump is based on the rotary motion of a screw in the pump chamber to transfer fluid.

Suction Phase

Fluid enters the pump chamber: As the screw rotates, fluid at the pump inlet is drawn into the pump chamber.

Formation of sealing cavities: A series of sealing cavities are formed between the screw and the wall of the pump chamber, and these cavities move from the suction inlet to the discharge outlet as the screw rotates.

Conveying Phase

Pushing Fluid: As the screw continues to rotate, these sealed cavities push the fluid axially along the screw. The screw’s helical structure ensures that the fluid is pushed smoothly toward the discharge port.

Maintaining Pressure: The design of the sealed cavities ensures that the fluid is conveyed at a constant pressure and flow rate.

Discharge Phase

Fluid Discharge: when the sealed cavity reaches the discharge port of the pump, the fluid is discharged from the pump cavity, completing a delivery cycle.

Characteristics of screw pumps

Continuous flow: Screw pumps provide smooth, pulsation-free flow as the fluid is uniformly pushed through the sealed cavity.

Efficient conveying: High conveying efficiency for fluids of high viscosity and containing solid particles.

High self-priming capability: Capable of self-priming the fluid when the pump is started, without the need for additional priming devices.

Screw pump Applications

- Oil and gas

- Chemicals

- Food and beverage

- Pharmaceuticals

- Paper and pulp

- Wastewater treatment

Types of Screw Pumps

Single Screw Pump

A single screw pump, also known as an eccentric screw pump or Mono pump, is a type of volumetric pump that utilizes a single rotating screw rotating within a stationary rubber or metal liner to convey fluids. Single screw pumps are widely used in various industrial fields because of their simple structure and adaptability.

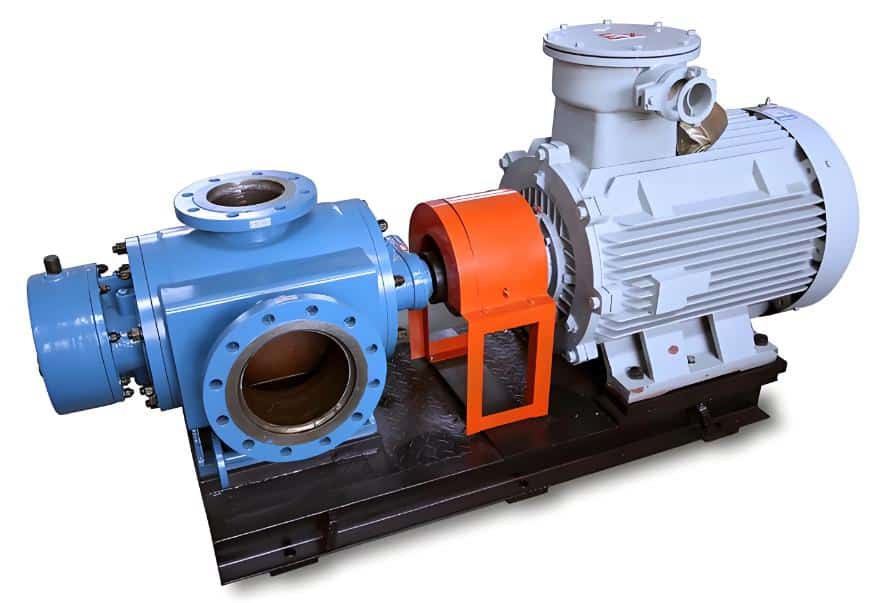

Twin Screw Pump

Twin screw pump is a twin screw positive displacement pump that utilizes the rotation of two intermeshing screws in the pump chamber to transfer fluid. The twin screw pump works similarly to the single screw pump, but with two screws running side-by-side, it has slightly different performance and application areas. It is suitable for handling highly viscous and shear-sensitive fluids and is therefore widely used in the chemical, petroleum, food, and pharmaceutical industries.

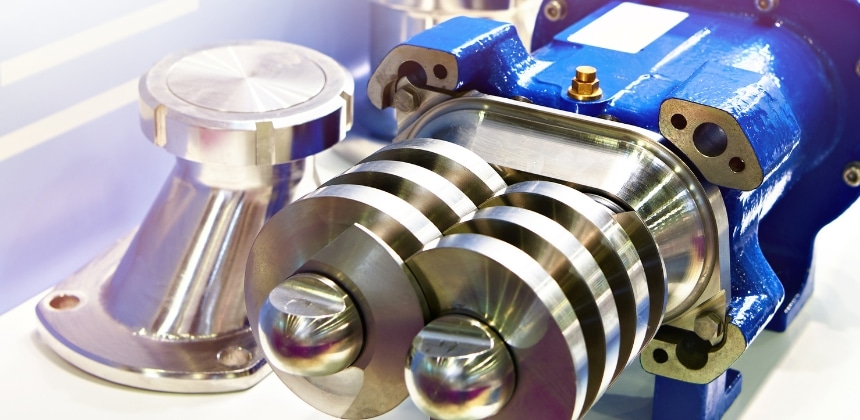

Triple Screw Pump

A triple screw pump utilizes three intermeshing screws to achieve fluid transfer. It usually consists of a driving screw and two driven screws, which engage with each other inside the pump casing to form a sealing chamber, thus conveying fluid from the suction port to the discharge port of the pump. It can be used in areas such as marine, machinery manufacturing, chemical, oil, and gas industries for handling high-pressure, high-viscosity, and high-temperature fluids.

Four Screw Pump

Four Screw Pump consists of four screws, usually including two active screws and two driven screws. The screws engage with each other inside the pump casing to form a sealing chamber. Due to the material and design of the screws, they are highly resistant to abrasion and corrosion. Fluid is conveyed by rotary motion. Four-screw pumps are usually used to handle fluids of high viscosity, high pressure, and high temperature, and are therefore widely used in petroleum, chemical, marine engineering, and machinery manufacturing.

Five screw pump

Five screw pumps are similar to triple screw pumps in that they are a type of positive displacement pump, but their main difference is the number of screws. Five screw pumps have five screws instead of three. Like the three-screw pump, the five-screw pump contains a drive rotor that drives all the remaining screws.

This type of pump is typically used in many applications, such as pipe oil or hydraulics. Because they have more screws, five-screw pumps are typically able to handle higher flow rates and provide a more consistent flow output when transferring fluids. In addition, five-screw pumps are also able to handle highly viscous, high-pressure, and high-temperature fluids, making them widely used in a variety of applications in industry.

Differences Between Gear Pumps and Screw Pumps

| Features | Gear pump | Screw pump |

| Structure | Consisting of two or more meshing gears | Consisting of one or more rotating screws and a fixed pump casing |

| Working principle | Fluid transportation relies on the clearance between gears | Fluid capture from pump suction to discharge |

| Applicable scenarios | Conveying of low viscosity fluids | High-viscosity, high-pressure and solid-particle-containing fluids |

| Stabilized output flow | Relatively stable output flow | Stable, pulsation-free flow output |

| Ease of maintenance | Easy maintenance | Complicated maintenance |

Advantages and Disadvantages of Screw Pumps

Advantages

- Wide range of applicability

- Stable flow output

- High performance

- High self priming capacity

- High corrosion resistance

- Low NPSH requirements

Disadvantages

- Risk of cavitation

- More complex structure in parts

- High lubricant requirements

- Sensitive to changes in fluid viscosity

- Susceptible to solid particles

Summary

Each type has unique benefits and application scenarios. Choosing the right type of progressive cavity pump for your application will help improve system efficiency, reduce energy consumption, and ensure consistent fluid transfer.

AOBL pump equipment is known for its high performance and reliability. Whether it is AODD pumps, electromagnetic diaphragm pumps, sanitary diaphragm pumps, filter press feed pumps or chemical pumps, and diaphragm pump parts. AOBL products excel in their performance and are able to operate stably under a wide range of demanding operating conditions. Contact us to develop a professional program.