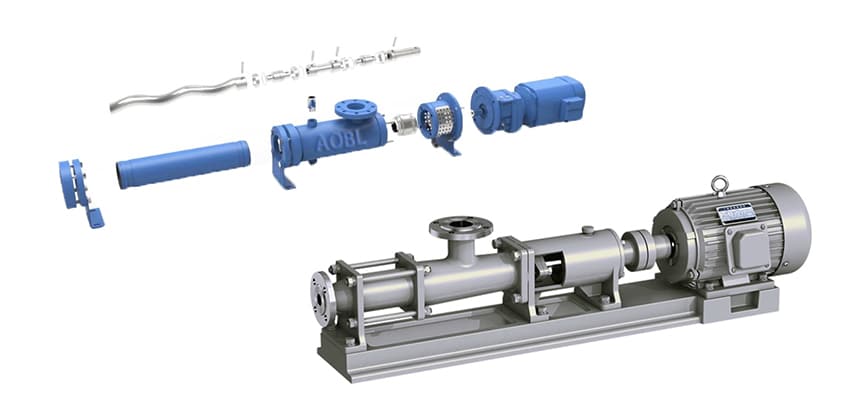

Food-grade hygienic progressive cavity pumps are used in the food, pharmaceutical, cosmetic and chemical industries for hygienic applications and optimal cleaning. Important features include continuous, pressure-stabilized, gentle, low-pulsation pumping and metering proportional to speed. The overflow material is stainless steel and the block pumps with flange drive are particularly compact and economical to operate.

Flow range: 0.8 m³/h – 60 m³/h

Maximum pressure: 1.2 Mpa

Overcurrent material: 304, 316

The compact design of the AOBL food and hygiene progressive cavity pumps provides optimal process characteristics for a wide range of food and hygiene applications. Due to the minimal pulsation and shear characteristics, they are also well suited for conveying sensitive foodstuffs.

Features

- High metering accuracy

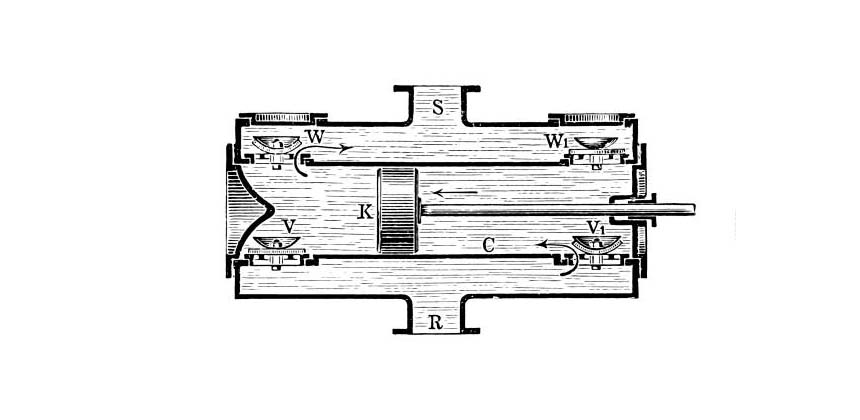

- Continuous low-pulsation pumping, independent of pressure and viscosity fluctuations

- Reversible pumping direction

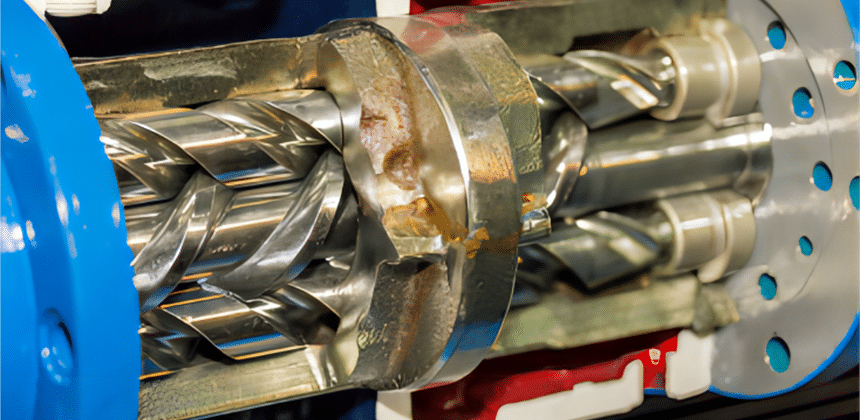

- Stator with chamfered inlet for optimal filling of the delivery chamber

- Gentle product handling

- Long production cycles due to contamination-proof, aseptic pump construction

- All product contact surfaces are polished to prevent product buildup and facilitate cleaning

- Easy maintenance

Applications

- Pharmaceuticals: all kinds of viscous slurry

- Daily chemical: emulsion, all kinds of ointment cosmetics

- Canned goods: a variety of viscous starch, cooking oil, honey, sugar sauce, fruit syrup, cream, minced fish and minced meat

- Brewing: all kinds of fermentation mucus, thick wine tanks, grain products slag all kinds of sauces, slurries and mucus containing block off the solids

Field case

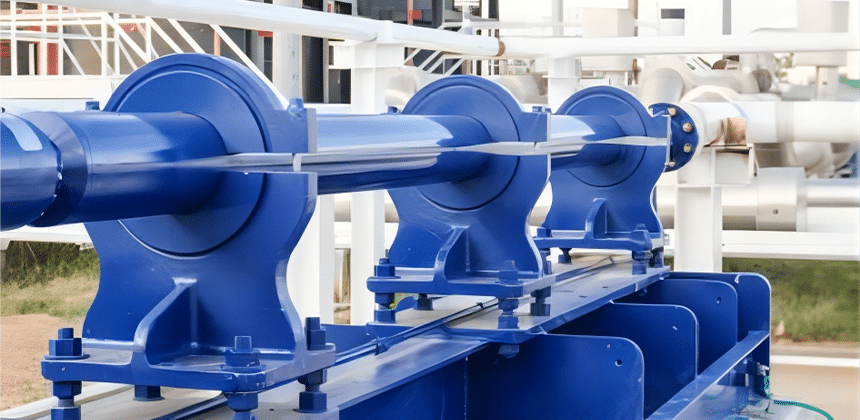

- Single screw pumps are used in wastewater treatment plants

- Single screw pump is used to transport sewage, PAM

| Brand | AOBL |

| Allowable particle diameter(mm) | 3.5, 4.5, 5.7, 7.1, 9, 11.4, 14.3, 17.9, 22.8 |

| Allowable fiber length(mm) | 20, 26, 32, 40, 51, 64, 80, 102, 128 |