AODD Pump

What is an Air-Operated Double-Diaphragm pump?

An AODD pump (Air-Operated Double Diaphragm Pump) is a pump that uses compressed air to drive a pump that transfers liquid through the reciprocating motion of two diaphragms. The main feature of this pump is that it does not require electrical power and is capable of transferring various types of liquids, including viscous, corrosive, or solid-particle-containing fluids. Because it is pneumatically driven, the AODD pump is ideally suited for environments with explosion-proof requirements or unstable power supplies.

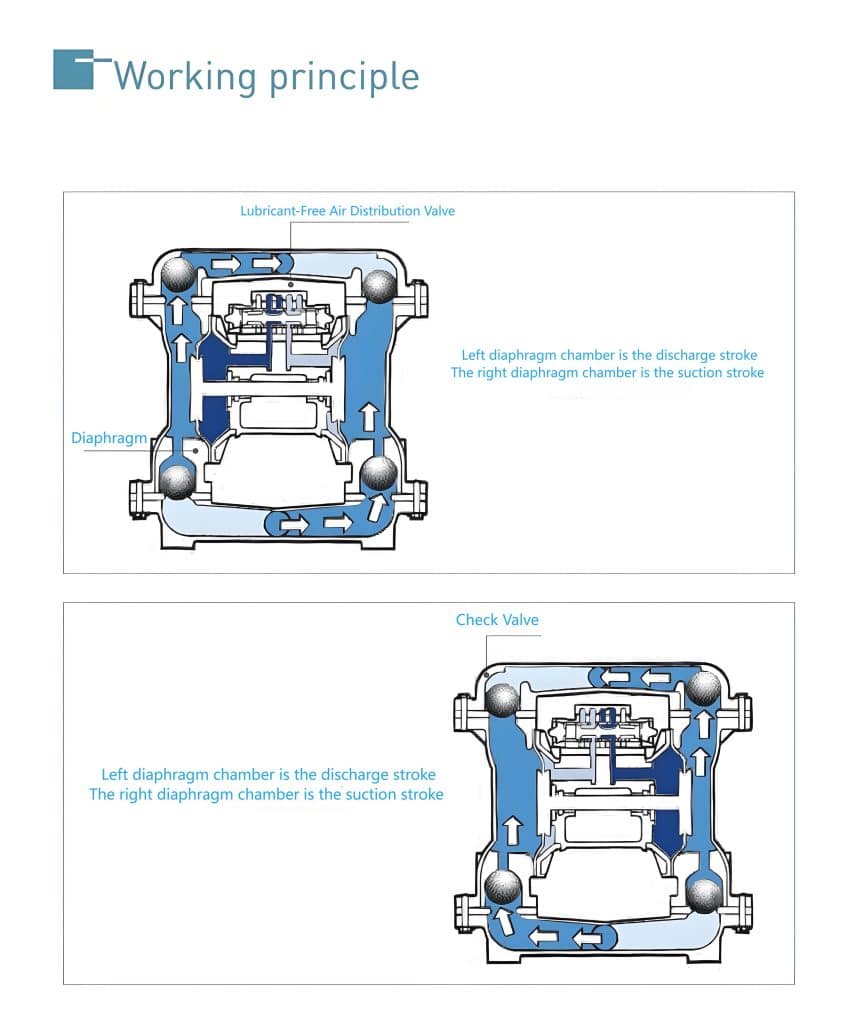

How does an AODD pump work?

The operating principle of the AODD pump is based on two diaphragms that move alternately. Compressed air enters through the air chamber of the pump and pushes one of the diaphragms, forcing liquid out through the pump outlet. The air is then diverted to the side of the other diaphragm, causing the other diaphragm to start reciprocating as well, thus drawing in new liquid. These two diaphragms work alternately to achieve continuous delivery of liquid.

Key Features and Benefits of AODD Pumps

Advantages

- No electricity required: AODD pumps are driven by compressed air and do not require electricity, so they are suitable for environments with unstable power supply or requirements for electrical safety.

- Self-priming ability: AODD pumps are self-priming and can start working even if no liquid fills the pump body.

- Handling a variety of fluids: it can handle a variety of viscous, corrosive or solid-particle-containing liquids, and is widely used in chemical, food, pharmaceutical and sewage treatment industries.

- Easy to maintain: AODD pumps are designed to be simple, easy to disassemble and clean, reducing the difficulty of maintenance.

- Explosion-proof function: due to its pneumatic drive method, AODD pump is very suitable for flammable and explosive environments.

Features

- No need for electric drive

- Self-priming capability

- Handles a wide range of fluids

- High pumping efficiency

- Seal-less construction

- Durable and adaptable

- Adjustable flow rate

- Wide range of adaptability

- no vibration, low noise

Considerations for selecting an AODD

1. Fluid Characteristics

- Viscosity: AODD pumps can handle fluids ranging from low viscosity to high viscosity. For thick liquids, a larger pump chamber or higher operating pressure may be required, so it is important to choose a pump size that can handle these conditions.

- Corrosiveness: For highly corrosive liquids, it is crucial to choose an AODD pump made from corrosion-resistant materials such as stainless steel, polyurethane, or PVDF. Material selection will directly impact the pump’s lifespan and the safety of the fluid being pumped.

- Solid Particles: AODD pumps are particularly suited for handling fluids containing solid particles or abrasives. If the fluid contains larger particles, ensure that the diaphragm and valves are capable of handling these particles without causing damage to the pump.

- Air Content: If the fluid contains air bubbles, AODD pumps typically handle this well due to their self-priming capability. They can efficiently process fluids that contain gases or air.

2. Required Flow and Pressure

- Flow Requirements: Understanding the required flow rate for your application is crucial. AODD pumps come in various flow ratings, and it’s important to select a pump that can meet the system’s needs.

- Pressure Requirements: Choose a pump based on the required head (pressure). AODD pumps are suitable for medium-low to medium-high pressure applications. If the application requires higher head, you may need to select a model with stronger air supply support.

3. Air Supply Conditions

- Compressed Air Source: AODD pumps rely entirely on compressed air for operation, so a stable air supply is essential. The capacity, pressure, and stability of the air compressor will impact the pump’s efficiency.

- Air Cleanliness: Compressed air must be filtered to avoid introducing impurities into the pump system, which could damage internal components and reduce pump performance.

4. Material Selection

- Pump Body and Diaphragm Materials: Choose appropriate materials based on the chemical nature of the liquid being pumped. Common materials include stainless steel, aluminum alloys, polypropylene, polyurethane, and PVDF. Consider factors such as the fluid’s corrosiveness, temperature, and particle size when selecting materials.

- Temperature Resistance: If the pumped fluid has a high temperature, it’s important to choose materials that can withstand these conditions, such as heat-resistant plastics or stainless steel.

5. Pump Size and Installation Space

- Pump Size: AODD pumps come in different sizes and configurations. Ensure the pump’s size fits within the available installation space and that it meets the required flow and pressure conditions.

- Installation and Layout: Verify the pump’s inlet and outlet connection types (e.g., flanged or threaded) to ensure compatibility with existing pipework systems.

6. Maintenance and Servicing

- Ease of Maintenance: AODD pumps have relatively simple designs that are easy to disassemble and maintain. When selecting a pump, consider whether the components (such as diaphragms, valves) are easy to replace, and if the necessary maintenance tools are readily available.

- Maintenance Intervals: Understand the durability of the pump components and the maintenance intervals. Choose pumps with components that have a long operational life and require minimal maintenance.

7. Explosion-Proof and Safety Requirements

- Explosion-Proof Design: If the application environment poses a potential explosion risk (e.g., in chemical or oil and gas industries), it’s essential to select an explosion-proof AODD pump to ensure safe operation in hazardous gas environments.

- Compliance with Standards: Ensure the pump meets relevant safety and quality certifications, such as ISO standards or ATEX certifications, especially in harsh industrial environments.

8. Fluid Handling Requirements

- Special Fluid Handling Requirements: Some fluids may have specific handling requirements, such as food-grade fluids or pharmaceutical-grade fluids. In these cases, the pump must meet hygiene standards and be capable of preventing cross-contamination.

Comparison of AODD Pumps With Other Types of Pumps

| Feature | AODD Pump | Centrifugal Pump | Piston Pump | Screw Pump |

|---|---|---|---|---|

| Drive Type | Compressed air | Electric or diesel engine | Electric or diesel engine | Electric or diesel engine |

| Suitable Fluids | Viscous, corrosive, solid-containing fluids | Clean water, low viscosity liquids | High viscosity, high pressure liquids | Viscous, non-Newtonian fluids |

| Self-Priming | Yes | No | Yes | Yes |

| Flow Rate | Low to medium flow | High flow | Medium flow | Low to medium flow |

| Suitable Pressure | Medium to high pressure | Low to medium pressure | High pressure | Medium to high pressure |

| Pumping Efficiency | Relatively low | High | High | High |

| Maintenance Needs | Easy maintenance | Regular maintenance needed | Complex maintenance | Regular maintenance needed |

| Noise | High | Low | Low | Low |

| Applications | Chemical, food, wastewater treatment, mining, etc. | Water treatment, industrial fluid transfer, irrigation, etc. | Liquid transfer, oil & gas, chemicals, etc. | Oil & gas, chemicals, food, etc. |

Table Of Comparison of AODD Pumps With Other Types of Pumps

Simplified Maintenance Procedure for AODD Pumps

Check the diaphragm: Check the diaphragm periodically for cracks or wear, and replace it if problems are found.

Check valves and seats: Check valves for clogging or damage and clean valves and seats to ensure proper operation.

Check the air supply system

- Make sure the compressed air source is stable and clean.

- Check air piping for leaks and ensure stable air pressure.

Check the pump body and connections: Check the pump body for cracks, corrosion, or leaks, and make sure the connections are tight.

Lubricate and clean

- Regularly lubricate the pump shaft and bearings to reduce friction.

- Clean the pump body and external components to prevent contaminant build-up.

Check pneumatic system pressure: Ensure air pressure is stable to avoid affecting pump performance.

Replace worn parts: Replace worn parts such as diaphragms, valves and seals periodically.

Record maintenance: Keep a maintenance record to track inspected and replaced parts.

Summary

AODD pumps are reliable and efficient for a range of applications, especially where electricity is unavailable or where there are safety concerns. Proper maintenance and careful selection of the right pump ensure long-term, efficient operation.

Aobl pump manufacturer always insists on technological innovation and constantly introduces new products to provide customers with better and more comprehensive water treatment solutions. If you have any questions about the article and the product, please feel free to contact our professional team to answer your questions.