Non Newtonian Fluid

Non-Newtonian fluids are a class of substances that do not follow the Newtonian law of fluid viscosity when flowing, and whose viscosity changes with changes in stress or shear rate. In industry and science, the study of non-Newtonian fluids is crucial for applications in fluid handling and pump technology.

What is a non-Newtonian fluid?

Non-Newtonian fluids are a class of substances whose viscosity (stickiness) does not follow the Newtonian fluid viscosity law when subjected to shear or stress. The viscosity of a Newtonian fluid is constant and independent of the shear rate, whereas the viscosity of a non-Newtonian fluid changes as the shear or stress changes.

Types Of Non-Newtonian Fluids

- Shear-thinning: In this type of fluid, the viscosity of the fluid decreases as the shear rate increases. This type of fluid includes particulate suspensions, some polymer solutions, etc.

- Shear thickening: The viscosity of this type of fluid increases as the shear rate increases. Typical examples include concentrated starch slurries, some polymer solutions, and some pastes.

The properties of non-Newtonian fluids make them important in many applications, such as in the food industry, the petroleum industry, the medical field, and chemical engineering. In these fields, the study of non-Newtonian fluids contributes to the understanding and optimization of production processes, to the improvement of product quality, and to the design of more efficient fluid control systems.

Different Types Of Non-Newtonian Fluids

Non-Newtonian fluids can be categorized into various types, mainly based on their rheological properties and viscosity response. Some of the common types of non-Newtonian fluids are listed below:

| Type | Characteristic | Examples |

| Shear Thinning | Viscosity decreases with increasing shear rate. | Plasma, solutions of particles in suspension. |

| Shear Thickening | Viscosity increases with increasing shear rate. | Concentrated starch slurries, solutions of certain polymers. |

| Plastic fluids | Flow only starts when the stress reaches a certain value, with a critical point of flow. | Magma, mud |

| Semi-solid | Have properties similar to solids and fluids, can flow but maintain a certain shape. | Gels, pastes |

| Particle Suspension | Fluid containing suspended particles, particles rearranged with shear. | Concrete, paints. |

| Bingham Plasticizer | Has the properties of a plastic fluid, but does not flow until it reaches its plastic limit. | Drilling mud, certain drawing inks. |

| Herschel-Bulkley fluid | Exhibits a nonlinear shear-strain relationship under stress. | Fruit pulp, cosmetics. |

Relationship Between Newtonian And Non-Newtonian Fluids And Viscosity

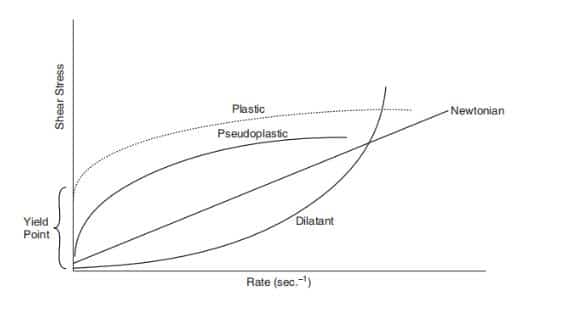

Newtonian and non-Newtonian fluids are two different types of fluids that exhibit significant differences in rheological properties and viscosity.

Newtonian fluids:

- Rheological properties: The rheological properties of Newtonian fluids are linear, i.e., the shear stress is proportional to the shear rate. This means that the viscosity of a Newtonian fluid is constant and does not vary with shear rate.

- Viscosity properties: The viscosity of a Newtonian fluid is a fixed value that can be described by Newton’s hydrodynamic model. Common examples are water, air, etc.

Non-Newtonian fluid:

- Rheological properties: The rheological properties of non-Newtonian fluids are nonlinear, and the relationship between shear stress and shear rate is not simply proportional. The behavior of the fluid may change with changes in stress or shear rate.

- Viscosity properties: The viscosity of a non-Newtonian fluid is usually not a constant value, but depends on the stress or shear rate to which the fluid is subjected. This makes it possible for non-Newtonian fluids to exhibit different viscosities under different stress conditions.

The viscosity of Newtonian fluids is constant, while the viscosity of non-Newtonian fluids is variable. Non-Newtonian fluids are more complex in practical applications and require consideration of their specific rheological properties and their behavior under different stress conditions.

Pumps For Non-Newtonian Fluids

Screw pumps: Suitable for handling high viscosity and non-Newtonian fluids, progressive cavity pumps are designed to efficiently convey fluids with varying viscosity, such as pasty substances or highly concentrated suspensions.

Centrifugal pumps: Centrifugal pumps generate centrifugal force using a rotating impeller, especially for fluids that are particulate or highly viscous, sending the fluid to the pump outlet. AOBL vertical chemical pumps are designed to convey acids, alkalis, highly corrosive chemicals and general hazardous liquids, suitable for conveying non-Newtonian fluids.

Plunger pump: Plunger pumps are suitable for the transportation of some non-Newtonian fluids due to their adjustable displacement and their ability to adapt to high pressure and high viscosity conditions.

When selecting a pump suitable for non-Newtonian fluids, the specific nature of the fluid, its rheological properties, and the process requirements need to be considered to ensure that the pump can handle the target fluid effectively and consistently.

Why are non-Newtonian fluids important?

Non-Newtonian fluids are important primarily because they play a key role in a variety of industrial and scientific applications, offering many unique properties and application advantages.

- Wide range of adaptations: Non-Newtonian fluids include a variety of forms such as slurries, gels, polymer solutions, etc., and their transition between liquid and solid states makes them adaptable to a wide range of application scenarios.

- Food and pharmaceutical Industries: Non-Newtonian fluids are commonly used in the food and pharmaceutical industries. Understanding their rheological behavior is essential for manufacturing processes, quality control and product development.

- Fluid control: The viscosity of non-Newtonian fluids is not fixed, which allows them to be engineered and manufactured with adjustable stresses for fluid control. This is important for mixing, pumping, spraying, and other fluid operations.

Summary

Research on non-Newtonian fluids and innovations in pump technology have complemented each other to advance the field of fluid handling. In industrial applications, the selection of the appropriate pump technology is critical to the effective handling of non-Newtonian fluids. Through continuous innovation and in-depth research, we are able to better understand the behavior of non-Newtonian fluids and design more efficient and reliable pump systems to meet the needs of different industries.

AOBL is a specialized company in the field of pumps, and our products and solutions are designed to meet the needs of a variety of industries including, but not limited to, industrial, chemical, food and beverage, and more. Offering air-operated diaphragm pumps, sanitary diaphragm pumps, magnetic drive pumps, chemical pumps, and parts, please contact us, no matter what kind of pumping challenges you are facing, the AOBL team is ready to provide professional support and customized solutions.