Dead Head Pump

In the world of industrial machinery and fluid dynamics, the term “dead head pump” often comes up, especially among engineers and maintenance professionals. But what exactly does it mean, and why is it important to understand? This blog will delve into the concept of dead head pumps, the potential issues they present, and how to handle them effectively.

What Is A Dead Head Pump?

A dead head pump refers to a situation where a pump continues to run but with its discharge valve closed, or with the flow path obstructed. In this condition, the pump is essentially pushing against a closed system, unable to move the fluid forward. This scenario can occur in various types of pumps, including centrifugal and positive displacement pumps.

The Dangers of Deadhead Pumps

- Overheating: The inability of the liquid to flow can cause the temperature of the liquid inside the pump to rise rapidly, potentially leading to pump overheating.

- High-pressure accumulation: As the pump continues to operate, pressure increases, but with the outlet closed, pressure accumulates inside the pump, potentially damaging the pump components or causing seal failure.

- Energy waste: In this state, the work done by the pump cannot be effectively utilized, leading to energy waste.

Why Is It So Hard To Spot A Dead Head Pump?

Lack of Direct Flow Indication

- No apparent external indication: In many cases, the pump’s exterior will not show its internal operating status, especially when the pump is enclosed within a system.

- Lack of real-time flow monitoring: If the system does not have flow sensors or monitoring equipment installed, operators may not be able to detect a zero-flow condition in a timely manner.

System Complexity

- Complex piping system: In complex piping systems, changes in flow may be difficult to detect, especially if the pump is part of the system rather than the sole source of flow.

- Interference from multiple pumps: In systems with multiple pumps operating simultaneously, the status of individual pumps may be obscured by the operation of other pumps, making it more challenging to detect a “dead head” pump condition.

Operator Perception

- Lack of experience: Operators who are unfamiliar with pump operation or lack experience may not have the skills to recognize a “dead head” pump condition.

- Misleading signals: In some cases, the pump may emit normal operating sounds or vibrations, but internally it has entered a “dead head” state, misleading the operators.

Characteristics of the Equipment

- Slow temperature and pressure changes: In certain situations, changes in temperature and pressure inside the pump may be slow, making the problem difficult to detect in a short period.

- Pump design tolerance: Some pumps are designed to tolerate short periods of “dead head” operation without showing obvious signs of failure, which can delay the detection of the issue.

Pumps Prone To Dead Head

Centrifugal Pumps: Since centrifugal pumps rely on fluid flow to cool and lubricate their internal components, if the outlet is clogged, the fluid inside the pump will not circulate efficiently, which can lead to overheating and damage.

Gear Pumps: Gear pumps generate very high pressures when the outlet is blocked, which can lead to damage to the pump mechanical parts and even rupture of piping.

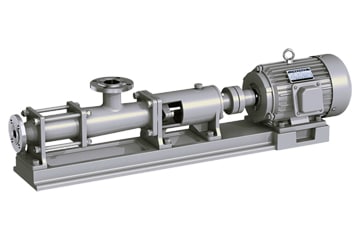

Screw Pumps: Screw pumps can experience a dramatic increase in pressure when the outlet is clogged, resulting in damage to the pump and system components.

Plunger Pumps: Plunger pumps in the “dead head” situation can generate extremely high pressures, which can cause serious damage to the pump seals and structure.

Diaphragm Pumps: Although diaphragm pumps are generally more resistant to clogging than other pumps, prolonged periods of “dead head” can lead to diaphragm wear and damage.

How Is It Found During Testing?

1. Flow Monitoring

- Flow sensors: Install flow sensors at the pump’s inlet and outlet to monitor flow in real-time. The sensors will trigger an alarm if the flow drops to zero.

- Differential pressure transmitters: By measuring the pressure difference between the pump’s inlet and outlet, the flow status can be indirectly determined. An abnormally high-pressure difference may indicate a flow blockage.

2. Pressure Monitoring

- Pressure sensors: Install pressure sensors at the pump’s outlet to monitor pressure changes in real time. If the pressure continues to rise and exceeds the set threshold, it may indicate the pump is in a “dead head” condition.

- Pressure relief valves: Install pressure relief valves in the system. These valves will automatically open to release pressure and trigger an alarm when internal pressure exceeds the safety threshold.

3. Temperature Monitoring

Temperature sensors: Install temperature sensors in the pump body or within the pump’s liquid to monitor temperature changes in real-time. A rapid temperature increase or a temperature that exceeds the normal operating range may indicate the pump is in a “dead head” condition.

4. Power Monitoring

- Current monitoring: Monitor the electrical current consumption of the pump motor. A sudden drop or steady current may indicate the pump is running idle with no flow.

- Power analyzers: Use power analyzers to monitor changes in the pump’s power consumption and determine whether the pump is operating normally.

5. Vibration Analysis

Vibration sensors: Install vibration sensors on the pump body to monitor the pump’s vibration patterns. Abnormal vibration patterns may indicate the pump is operating in a “dead head” condition.

Summary

Dead head pumps are used in a wide range of industrial and commercial applications as an efficient and reliable fluid transfer device. Its excellent performance and durability make it the preferred choice for many critical engineering projects. However, as technology continues to advance, so do pump designs and features.

In this process, AOBL dead head pumps not only excel in performance and reliability but also offer significant advantages in terms of energy efficiency and environmental protection. Choosing us is choosing quality and trust for your project.