Dilatant Fluid

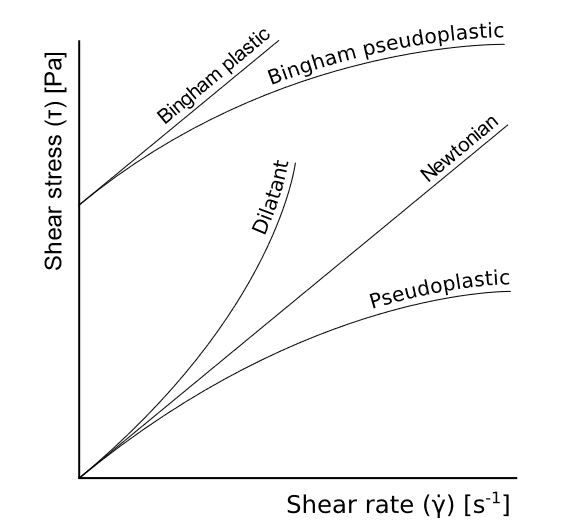

In addition to traditional Newtonian fluids, there exists a special class of fluids called non-Newtonian fluids. One of these striking non-Newtonian fluids is the dilatant fluid, whose behavior is significantly different from that of the familiar Newtonian fluids, the expansive fluids are not the same as the others.

What is a dilatant fluid?

Dilute fluids are fluids whose viscosity and flow properties increase with increasing shear rate when subjected to external shear forces. This type of fluid typically exhibits shear-thickening properties and is also referred to as an inverting fluid or a shear-thickening fluid. In expansive fluids, increased friction between particles increases the viscosity of the fluid, which causes it to exhibit harder and more solid properties when subjected to forces.

When viscosity increases with agitation (shear rate), these fluids are said to swell. Swelling properties are not usually found in pure materials, but usually in suspensions, mixtures, or compounds. Examples include clay, mud, and playdough.

Importance of Dilatant Fluids

- Industrial applications

- Scientific research

- Geological exploration

- Medical applications

Relationship between fluids

| Characteristics | Dilatant Fluids | Thixotropic Fluids | Pseudoplastic Fluids |

| Properties | Viscosity increases as flow rate increases. | Fluid becomes thicker or harder when shear is applied. | Specialized rheological properties. |

| Examples | Corn starch and water mixtures. | Corn starch and water mixtures. | Traditional Newtonian fluids such as water and oil. |

| Rheology curve shapes | Flattening curve with shear rate. | Shows a step or S-shaped curve with shear rate. | May exhibit different behavior under specific conditions. |

| Field of application | Rubber, sponge, etc. | Food, cosmetics, chemicals, etc. | Cosmetics, lubricants, adhesives, paints, etc. |

Dilatant fluids increase in viscosity as the flow rate increases, a typical example being corn starch and water mixtures. Thixotropic fluids become thicker or harder when shear is applied, such as corn starch and water mixtures. Pseudoplastic fluids have specific rheological properties where the viscosity varies with shear rate, such as conventional Newtonian fluids like water and oil, but with specific substances added to change their rheological properties. They have a wide range of applications in different application areas including food, cosmetics, chemicals, rubber, sponges, and others.

Pumps for Dilatant Fluids

Low Shear: The fluid becomes denser when subjected to force to avoid additional shear on the fluid, thus preventing the fluid from becoming thicker or hardening.

Constant Pressure Transport: Viscosity increases as the shear rate increases, so pumps need to be able to provide constant pressure to ensure that the fluid maintains stable flow properties during transport.

Corrosion resistance: According to the characteristics of Dilatant Fluids and the different processing environments, it is necessary to select the appropriate materials and coatings to ensure that the pump has good corrosion resistance in long-term use.

Good sealing performance: In the force that may produce high pressure, the pump needs to have good sealing performance to prevent leakage and fluid waste.

Adjustability: This may change with the processing conditions, the pump needs to have adjustable operating parameters to adjust and optimize according to the actual needs.

Types of Pumps for Transferring Dilatant Fluids

Diaphragm Pumps: Diaphragm pumps are often suitable for transferring Dilatant Fluids due to their design to handle highly viscous and deformable fluids. They are driven by pneumatically or electrically powered transmission of compressed air or electric motors that move the diaphragm as it sucks in and discharges the fluid. AOBL KES50 plastic diaphragm pump are suitable for handling condensable and corrosive liquids as their design does not require dynamic seals.

Plunger pumps: Plunger pumps generate fluid pressure by moving a plunger up and down inside the plunger chamber and are suitable for transferring highly viscous and deformable fluids. These pumps are typically used in applications requiring flow accuracy and pressure control, such as chemical, pharmaceutical, and food processing.

Screw pumps: Screw pumps utilize the movement of a screw between the rotor and the casing to convey fluids, and are suitable for handling fluids that are highly viscous, hot, and prone to crystallization. They are commonly used in oilfield extraction, chemical, paper, and sugar industries.

Submersible Pumps: Submersible pumps are commonly used to pump fluids from wells or water sources and can be suitable for transferring expansive components of liquids. Their design allows them to operate directly in the liquid without the need for an additional suction pipe.

Centrifugal pumps: Centrifugal pumps increase the kinetic energy of a liquid by rotating an impeller and transferring it into a pipe or container. While centrifugal pumps are typically used to transfer low-viscosity liquids, certain types of centrifugal pumps can also be suitable for handling viscous fluids such as gels and high solids mixtures.

Summary

Dilatant fluids are a special class of liquids that become denser and more solidified under force. Their non-Newtonian rheological properties make them require special attention and proper pump selection during handling and transfer. Understanding the nature and characteristics of dilatant fluids is critical to the proper selection and operation of pumping equipment.

AOBL, as a leading pump manufacturer, covers a wide range of pumps including electric diaphragm pumps, sanitary diaphragm pumps, filter press feed pumps, chemical pumps, and accessories to meet the needs of different industries and sectors. Contact us to develop a program for you.