Efficiency of Centrifugal Pump

Centrifugal pumps, as important equipment in the field of fluid transportation, play a vital role in both industrial and civil applications. Whether it is conveying water from the ground to the city water supply system or chemical liquids(vertical chemical pump) from one process to another, centrifugal pumps are indispensable. Efficiency is a crucial indicator in the performance evaluation of centrifugal pumps.

Meaning of centrifugal pump efficiency

The importance of the efficiency of centrifugal pumps on energy consumption and costs cannot be ignored. First of all, a highly efficient centrifugal pump means that less energy is required to transport fluids, and therefore energy consumption can be reduced. This is crucial for energy management in areas such as industrial production and residential water supply(vertical multistage pump), which can effectively reduce energy bills and lower operating costs, thereby enhancing the competitiveness of enterprises.

Secondly, high-efficiency centrifugal pumps can also reduce the negative impact on the environment. By reducing energy consumption, greenhouse gas emissions and the release of other pollutants can help protect the environment and mitigate the effects of climate change. Therefore, the use of high-efficiency pumps is one of the most important initiatives to realize green and sustainable development.

In the context of sustainable development, enterprises and society are increasingly demanding energy saving, emission reduction and effective resource utilization. The choice of high-efficiency centrifugal pumps not only reduces operating costs and improves production efficiency, but also establishes a good environmental image for the enterprise and enhances the competitiveness of sustainable development. Therefore, the sustainable development value of high-efficiency pumps is not only reflected in the economic level, but also in the level of environmental protection and social responsibility.

Calculation of centrifugal pump efficiency

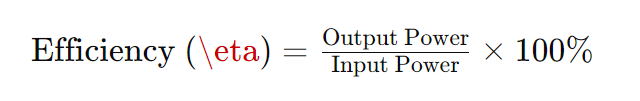

The efficiency of a centrifugal pump can be calculated using the following formula:

In this case, the output power is the power provided by the pump when delivering fluid, usually expressed in kilowatts (kW). The input power is the total power consumed by the pump, including the power of the motor and the internal losses of the pump, usually in kilowatts (kW).

When calculating efficiency, the following parameters and units need to be noted:

- Output power: Indicates the power provided by the pump to convey the fluid in a unit of time, usually in kilowatts (kW). Can be calculated through the flow, head and fluid density and other parameters.

- Input power: the total power consumed by the pump, including the input power of the motor and the pump’s internal losses. Usually in kilowatts (kW) for the unit.

- Efficiency: Indicates the pump’s ability to convert input power into useful work, usually expressed as a percentage (%). A high-efficiency pump means that less energy is consumed in transferring the fluid, so the higher the efficiency, the more efficient the use of energy.

By calculating the efficiency of centrifugal pumps, it is possible to assess their performance strengths and weaknesses and to provide an important reference for optimizing the pump system and improving the efficiency of energy use.

Factors affecting the efficiency of centrifugal pumps

Pump design

- Impeller geometry: The design of the impeller directly affects the fluid flow state and energy conversion efficiency. Impeller geometry, the number of blades, blade curvature and other parameters will affect the kinetic energy conversion efficiency of the fluid.

- Casing design: the design of the pump casing will also affect the fluid flow and pump efficiency. Reasonable casing design can reduce the fluid turbulence loss and energy loss, improve the efficiency of the pump.

Working conditions

- Flow: Flow is one of the important parameters affecting the efficiency of centrifugal pumps. The efficiency of the pump may vary under different flow conditions.

- Head: The head is the height of pressure that the pump can provide, which also affects the efficiency of the pump. Typically, as the head increases, the pump’s efficiency may decrease.

- Speed: The speed of the pump also has a significant impact on its efficiency. The right speed can make the pump in the best working conditions, improve efficiency.

Pump status

- Degree of wear: Wear and tear on pump components reduces the efficiency of the pump. Wear on the impeller and pump casing surfaces increases friction losses and reduces pump efficiency.

- Material quality: The material quality of pump components directly affects the performance and durability of the pump. High-quality materials can reduce wear and loss and increase the efficiency and service life of the pump.

Methods to improve the efficiency of centrifugal pumps

- Regular maintenance and inspection: Regularly clean, lubricate and fasten the centrifugal pump for maintenance work to ensure that the pump equipment is in good working condition. Regularly check the wear and tear of the pump’s impeller, bearings, seals and other parts, and replace damaged parts in time to reduce friction loss and improve pump efficiency.

- Select the appropriate pump type and size: Select the appropriate centrifugal pump type and size according to the process requirements, fluid characteristics and system characteristics. The appropriate pump type and size can better meet the process requirements and improve the efficiency and operational stability of the pump.

- Operate near the point of optimum efficiency: Ensure that centrifugal pumps operate near their point of optimum efficiency to avoid overloading and inefficient operation. Overloaded operation leads to wasted energy and equipment damage, while inefficient operation increases energy consumption and operating costs. Maximize the efficiency of your pumps by designing and controlling the system so that they operate consistently near their optimum efficiency point.

Through the above methods, you can effectively improve the efficiency of centrifugal pumps, reduce energy consumption, reduce operating costs, while prolonging the service life of the pump equipment, improve the reliability and stability of the system.

Summary

In conclusion, centrifugal pumps, as common fluid transfer equipment, play an indispensable role in industrial and civil fields. Its efficiency is one of the key indicators for assessing its performance, which directly affects energy consumption and operating costs. Therefore, by focusing on the efficiency of centrifugal pumps and taking appropriate measures to optimize it, a more efficient and sustainable fluid transfer process can be achieved.

AOBL is a specialist in fluid transfer and in addition to centrifugal pumps also offers air operated diaphragm pumps, electric diaphragm pumps, progressive cavity pumps, magnetic drive pumps and their accessories. Please contact us if you have questions.