Head Loss of Pump

In the world of fluid mechanics, understanding the concept of head loss is essential for anyone involved in designing, operating, or maintaining fluid systems. Whether you’re working with water pipelines, industrial pumps, or HVAC systems, head loss plays a critical role in ensuring efficient and effective fluid transport.

What is Head Loss?

Head loss refers to the reduction in the total head (sum of potential energy, kinetic energy, and pressure energy) of the fluid as it moves through a pipeline or any other fluid system. This loss is primarily due to friction and turbulence within the system, which convert some of the fluid’s energy into heat. Head loss is a key factor in determining the performance and efficiency of fluid transport systems.

Types of Head Loss

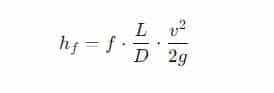

Major head loss: This occurs due to friction between the fluid and the inner surface of the pipeline. The Darcy-Weisbach equation is commonly used to calculate major head loss:

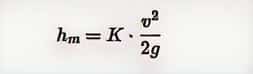

Minor gead loss: This is caused by fittings, bends, valves, and other components in the system that create additional resistance to flow. It can be calculated using:

Impact of Head Loss on Pump Systems

Head loss is a critical factor in the design and selection of pumps.

Centrifugal Pump

A centrifugal pump relies on a rotating impeller to impart kinetic energy to the fluid, increasing its pressure and velocity. The impact of head loss on centrifugal pumps primarily manifests in the following aspects:

- Reduced head: An increase in head loss will lead to a higher total head requirement for the system. The pump must provide more energy to overcome these losses, reducing the available head.

- Reduced efficiency: The efficiency of a centrifugal pump is highest at a specific operating point (Best Efficiency Point, BEP). Head loss alters the pump’s operating point, causing it to deviate from the BEP, thus lowering the pump’s operational efficiency.

- Decreased flow rate: Increased head loss means the pump must overcome greater resistance, reducing the flow rate. This impact is especially pronounced in long-distance transport or high-resistance systems.

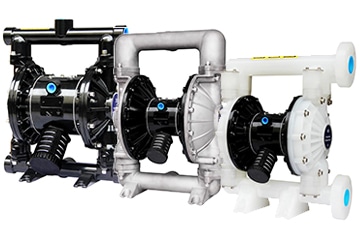

Diaphragm Pump

A diaphragm pump uses the reciprocating motion of a diaphragm to pump fluid, suitable for transporting high-viscosity, corrosive, or particulate-laden fluids. The impact of head loss on diaphragm pumps includes:

- Increased pressure requirement: Increased head loss means the pump needs to generate higher pressure to maintain the same flow rate. This can lead to an increased workload for the diaphragm pump, affecting its lifespan and reliability.

- Flow rate fluctuations: Since diaphragm pumps inherently have a pulsating flow, increased head loss may exacerbate these fluctuations, impacting system stability. Using a pulsation dampener can partially mitigate this issue.

- Increased energy consumption: Similar to centrifugal pumps, diaphragm pumps also need to consume more energy to overcome additional head loss, thereby increasing operational costs.

Gear Pump

A gear pump is a type of positive displacement pump that uses the rotational motion of gears to transport fluid. Gear pumps are suitable for transporting high-viscosity fluids such as oil and resin.

Impact:

- Sensitivity to head loss: Gear pumps are less sensitive to head loss because they generate pressure through mechanical motion rather than relying on the fluid’s kinetic energy.

- Efficiency decline: Larger head losses in the system can lead to a decrease in the pump’s efficiency, particularly in long-distance transport or when handling high-viscosity fluids.

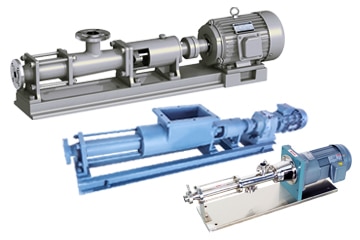

Screw Pump

A progressive cavity pump is a type of positive displacement pump that uses the rotation of screws to transport fluid from one end to the other. Screw pumps are suitable for transporting high-viscosity and particulate-laden fluids.

Impact:

- Overcoming High Head Loss: Screw pumps can overcome high head losses, but they require more energy to maintain the flow rate.

- Efficiency Reduction: Increased head loss in the system will lower the pump’s operational efficiency, especially in long-distance or high-head applications.

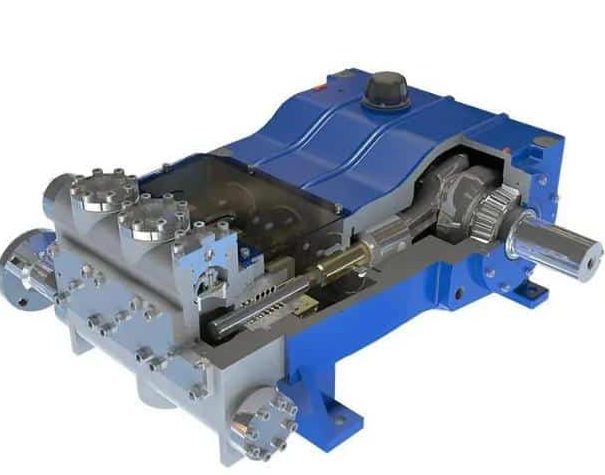

Reciprocating Pump

A reciprocating pump uses the reciprocating motion of a piston to transport fluid, suitable for high-pressure, low-flow applications such as hydraulic systems and chemical injection.

Impact:

- Sensitivity to Head Loss: Reciprocating pumps are less sensitive to head loss because they exert direct mechanical force on the fluid.

- Increased Workload: Larger head losses can increase the pump’s workload, leading to higher energy consumption and increased wear and tear on pump components.

Considerations for Choosing The Right Pump

Fluid characteristics: Diaphragm pumps are better for high-viscosity, abrasive, or corrosive fluids, while centrifugal pumps are more efficient for low-viscosity, clean fluids.

Flow Rate and Head Requirements: Centrifugal pumps are suitable for high-flow, low-head applications, whereas diaphragm pumps are better for lower flow rates and higher pressure needs.

System Design: The overall design, including the piping length and number of fittings, will affect head loss and, consequently, pump performance.

Summary

Head loss is a critical factor in fluid mechanics that affects the performance and efficiency of various pumping systems. By understanding its types and impacts, one can make informed decisions in pump selection and system design to ensure optimal operation and cost-effectiveness.

AOBL pump manufacturer is constantly investing in research and development to improve performance and develop new pumps. We offer various types of pumps and can also provide pump accessories such as spare parts, filter regulator lubricators, etc. Welcome to contact us for your service.