NPSH Of Pump

During pump design and operation, ensuring that the pump operates within a safe NPSH (Net Positive Suction Head) range is critical. too low an NPSH can lead to cavitation, seriously affecting pump performance and life.

What is NPSH for pumps?

The Net Positive Suction Head (NPSH) of a pump is a key performance parameter that describes the minimum pressure required at the suction side of the pump during operation to prevent cavitation from occurring. Cavitation can affect pump operation by causing damage and loss of efficiency.

Definition of NPSH

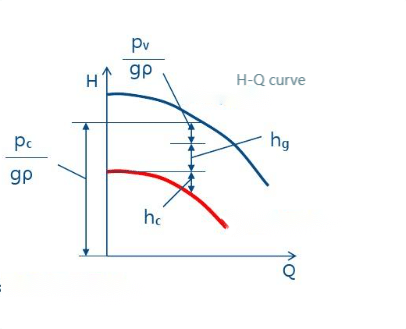

NPSH has two main parameters:

- NPSH requirements (NPSHr): Indicates that the pump operates at a certain flow rate, to prevent cavitation of the minimum suction pressure required.

- NPSH available (NPSHa): Indicates that the system in the pump suction inlet provides the suction pressure.

Factors Affecting NPSH

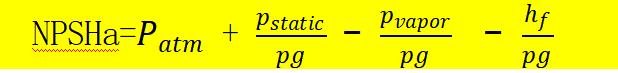

1. Atmospheric Pressure (Patm)

Atmospheric pressure is a component of NPSHa and is usually dependent on altitude. The higher the altitude, the lower the atmospheric pressure and the lower the NPSHa. Increased liquid level height or reduced pipeline resistance is required.

2. Liquid Level (Pstatic)

The higher the liquid level height, the higher the static pressure and the higher the NPSHa. Ensure sufficient liquid level height at the suction inlet of the pump to minimize level fluctuations.

3. Liquid temperature (Pvapor)

The temperature of a liquid affects its vapor pressure; the higher the temperature, the higher the vapor pressure of the liquid and the lower the NPSHa. When operating a pump at high temperatures, the effect of temperature on NPSHa must be calculated and taken into account, and the liquid needs to be cooled or the suction temperature of the pump lowered.

4. Suction Pipe Friction Loss (hf)

Friction losses in the suction piping include pressure losses due to piping, valves, elbows, etc. Try to use larger pipe diameters and streamlined pipe fittings to reduce the number of elbows and valves.

5. Liquid Properties

The viscosity and density of the liquid also affect NPSH. High viscosity liquids increase friction losses and reduce NPSHa. High-density liquids increase hydrostatic pressure but also increase friction losses. When designing a pump system, it is important to consider the nature of the liquid and select a pump and piping configuration that is appropriate for handling that liquid.

6. Changes In System Dynamics

Dynamic changes in the system, such as level fluctuations, pump startup and shutdown, etc. Pump startup and shutdown are prone to transient high friction losses. Install automated monitoring equipment to monitor NPSHa in real-time and design buffers to cope with dynamic changes.

7. Pump Design And Operating Conditions

NPSHr is usually higher when the pump is operated at high flow rates and high speeds. Different types of pumps (centrifugal pumps, axial flow pumps, mixed flow pumps) have different requirements for NPSHr.

What is the most susceptible to cavitation?

A. Low-pressure side near the inlet edge of the blade at the front cover plate where the curvature of the impeller is greatest;

B. The low-pressure side near the inlet edge of the worm shell spacer tongue and guide vane in the press-out chamber;

C. The sealing gap between the outer circle of the blade tip and the casing and the low-pressure side of the blade tip in the high-ratio impeller without a front cover plate;

D. The first stage impeller in a multistage pump.

Selection Of Industries And Applications For NPSH

| Industries | Recommended NPSH Margin | Clarification |

| Municipal Water Supply | 0.5-1 M | Clean water with a relatively small NPSH margin. |

| Sewage Treatment | 0.5-1 M | Impurities and deposits may be present, ensuring an appropriate NPSH margin to prevent clogging and cavitation. |

| Chemical Industry | 1-2 M | The chemical industry is characterized by complex and highly corrosive liquids that require higher NPSH allowances. |

| Oil and Gas | 1-2 M | The liquid may have high temperature, high pressure, and high viscosity, etc., need enough NPSH. |

| Pharmaceutical Industry | 0.5-1.5 M | The operating conditions of the pump need to be strictly controlled to ensure accurate and safe NPSH margins for pharmaceutical production. |

| Paper Industry | 1-2 M | Contains fibers and impurities that can cause cavitation and wear of the pump. |

| Food and Beverage Industry | 0.5-1.5 M | Contains particles and floating matter, requiring an appropriate NPSH margin. |

How to choose a pump based on NPSH?

Centrifugal Pump

Centrifugal pumps are one of the most commonly used types of pumps for a wide variety of industrial and municipal applications. NPSHr values are usually high and increase as the flow rate increases. High flow rate, high head, simple structure, easy maintenance. The selection needs to ensure that the NPSHa is higher than the NPSHr, usually requiring a margin of 0.5 to 1 meter.

Screw Pump

Screw pumps are suitable for conveying high-viscosity liquids and media containing solid particles.NPSHr values are usually low, suitable for low NPSHa systems. High self-priming capacity, suitable for high viscosity liquids, smooth output.

Diaphragm Pump

Diaphragm pumps are self-priming and are widely used where corrosive, highly viscous, or solid particle-laden liquids need to be handled. Diaphragm pumps usually have low NPSHr values and are suitable for systems with low NPSHa.

Chemical Pump

Chemical pumps are used to convey a variety of chemical media and require high corrosion resistance.

According to the specific design and application, the NPSHr value of chemical pumps can vary greatly. Chemical pumps are highly corrosion-resistant and suitable for a variety of chemical media. The selection should be based on specific media characteristics and system conditions to ensure that NPSHa is higher than NPSHr.

Summary

NPSH is a critical parameter in pump design and system operation. Through proper understanding and management of NPSH, cavitation can be effectively prevented, pump efficiency and reliability can be improved, and the service life of the equipment can be extended. In the process of pump selection and system design, NPSH must be fully considered to ensure optimal pump operation.

AOBl Pump Manufacturing is a supplier of efficient fluid transfer solutions for all types of industrial manufacturing processes, offering a range of pumps, in addition to the pumps listed above we also have specialist sanitary diaphragm pumps, filter press feed pumps, magnetic drive pumps, spare parts, pulsation dampers and filter regulator lubricators. Feel free to contact us for your specialized solutions.