Types Of Pulsation Dampener

Pulsation dampers play a vital role in pump systems. Its main goal is to reduce the pulsations and vibrations that can occur during pump operation to ensure that the flow in the system remains smooth and consistent while reducing pipe vibrations. The presence of this device helps to maintain the accuracy of fluid transfer and reduces the vibration levels in the system.

Definition Of Pulsation Damper

What is a pulsation damper?

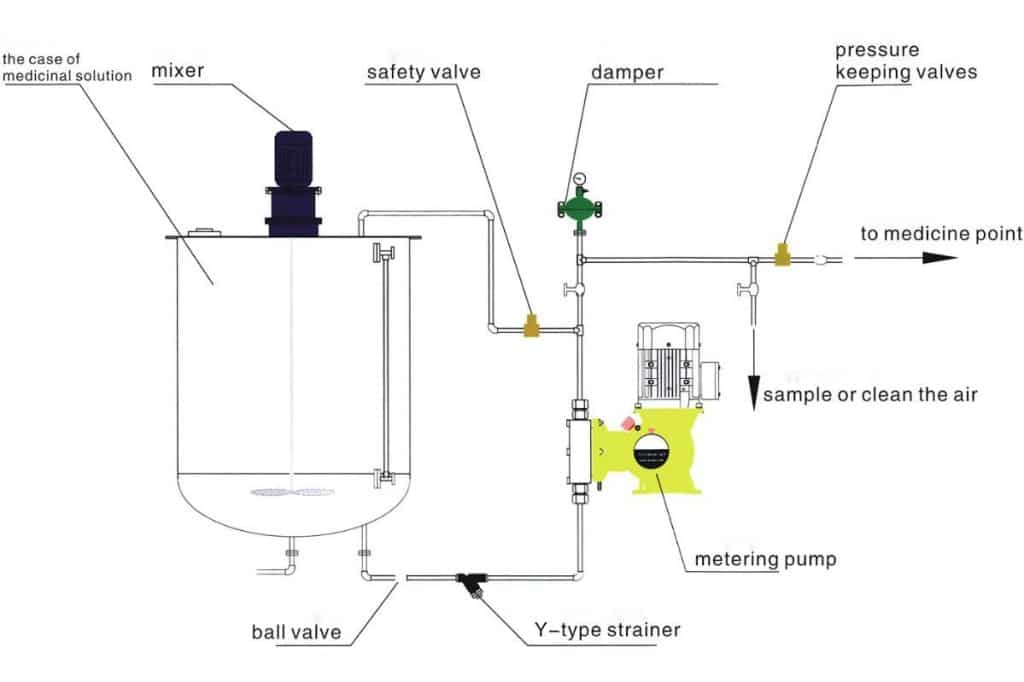

A pulsation damper is a device used to slow or absorb pressure pulsations or pulsations in a fluid system. It is typically installed in the piping of a pump or pressure system and is designed to smooth the flow of fluid in the system and reduce the pulsations and shocks caused by pump operation. It is a must-have accessory for volumetric pumps (such as metering pumps, double diaphragm pumps, peristaltic pumps and hose pumps, etc.)

What is it used for?

The reciprocating motion characteristics of positive displacement pumps can create pulsations or pressure gaps that can damage the entire pump system over time. The opening and closing of pump check valves can also cause pressure gaps. Pulsation dampers act much like shock absorbers in automobiles to dampen the resulting hydraulic shock and minimize pipe vibration and pressure fluctuations. A solid pulsation damper will reduce the amount of energy present in the pumping medium, thereby increasing the efficiency of other tools used in the system.

By minimizing shock and excessive motion, the pulsation damper reduces damage to system components, especially pipe welds and supports. The result is increased pump efficiency, safety, reliability, and reduced downtime, maintenance and operating costs.

Pulsation damper working principle

The pulsation damper works on the same principle as the compressed air supplying the pump. The compressed air introduced into the counter-pressure chamber behind the membrane creates a pneumatic damping cushion that is self-regulating in response to the stresses exerted by the fluid pressure pulses generated by the pump.

Types of pulsation dampers

- Expansion Pulsation Dampener: This type of pulsation damper typically contains an expandable gas chamber or membrane that absorbs the pulsations of the fluid. As the fluid pulsates through the system, the chamber expands or contracts, smoothing out pressure fluctuations.

- Diaphragm Pulsation Dampener: This type uses a flexible membrane or diaphragm to separate the liquid from the gas. When the liquid pressure fluctuates, the membrane deforms, absorbing the pulsation and keeping the system stable.

- Piston Pulsation Dampener: This type consists of a piston that absorbs pulsations by moving between the liquid and the gas chamber. As the liquid pulsates, the piston moves, adjusting the volume of the gas chamber to smooth the pressure.

- Rotary Pulsation Dampener: This type of pulsation damper usually includes rotating parts, such as a spinning shaft or windmill. These rotating parts help to slow down the pulsations in the fluid flow.

- Helical Pulsation Dampener: This design utilizes a helical structure, where the shape of the helix is adjusted to smooth out the pulsations of the fluid.

Each type of pulsation damper has specific application scenarios and advantages and disadvantages, and selecting the right type for a particular system requirement is critical to effectively mitigating pressure pulsations.

Risks From Fluid Pulsation

Within a hydraulic system, fluid pulsations can lead to the phenomenon of water hammer, which consists of pressure spikes caused by sudden changes in flow within a pipe or sudden closure of a valve. The effects of water hammer vary depending on the size of the pipe, fluid velocity and density, but typically cause extensive damage to system components. To protect the system from water hammer and vibration, AOBL Pulsation Damper can be used, which automatically adapts to the pump’s operating conditions.

Application background of pulsation dampers

The pulsation damper is a device with a wide range of applications in fluid engineering, hydraulic systems, piping networks, hydraulic valves, and control systems, industrial production equipment, used in chemical conversion processes, petrochemicals, use in the field of mining.

Pumps for pulsation dampers

Centrifugal pumps: Centrifugal pumps create pulsations in the transfer of liquids, and pulsation dampeners can be used to mitigate such pulsations.

Diaphragm pumps: Diaphragm pumps propel liquids through the reciprocating motion of membranes, which can cause pulsations in the system. Pulsation dampeners can reduce the effects of this pulsation. AOBL KES50 combines maximum performance and efficiency with superior sealing, reducing internal friction enough to handle corrosive liquids and small suspended solids.

Piston and piston pumps: Piston and piston pumps typically produce large pulsations, especially under high pressure and high flow conditions. Reciprocating pumps are included and are positive displacement pumps. The use of pulsation dampeners in these pumps helps to adjust pump output and smooth fluid flow. Pulsation dampeners help reduce pump-induced water hammer and improve system smoothness.

Screw pump: Screw pump are positive displacement pumps typically used to transfer high-viscosity fluids. They can also cause fluid pulsation under some operating conditions, and pulsation dampeners can be used to smooth fluid flow. Eccentric screw pumps, also known as single screw pumps, due to the pump’s adaptability to the medium, smooth flow, good suction performance, small pressure pulsation, in addition to conveying a variety of flowable media, but also can be transported to high-viscosity media, media containing hard suspended particles or solids. Granular media, media containing fibers.

It is important to note that the selection and suitability of pulsation dampers also depends on the specific hydraulic system requirements as well as the operating conditions of the pump. When selecting a pulsation damper, parameters such as the flow rate, pressure and pulsation frequency of the hydraulic system need to be considered to ensure that the pulsation damper can work effectively.

Summary

Dynamic dampers are critical in pump operation. Their main goal is to reduce pulsations and vibrations in the pump system to ensure smoother and more accurate fluid transfer, while reducing vibrations in the piping system.

AOBL is a fluid transfer specialist offering electric diaphragm pumps, filter press feed pumps, magnetic drive pumps, chemical pumps, and air filter regulator lubricators, contact us to speak with one of our dedicated technical teams!