What Is A Magnetic Drive Pump?

Magnetically driven pumps use a magnetic drive and do not require mechanical seals. They are designed to convey a wide range of liquids and are particularly suitable for industrial applications requiring high sealing and safety.

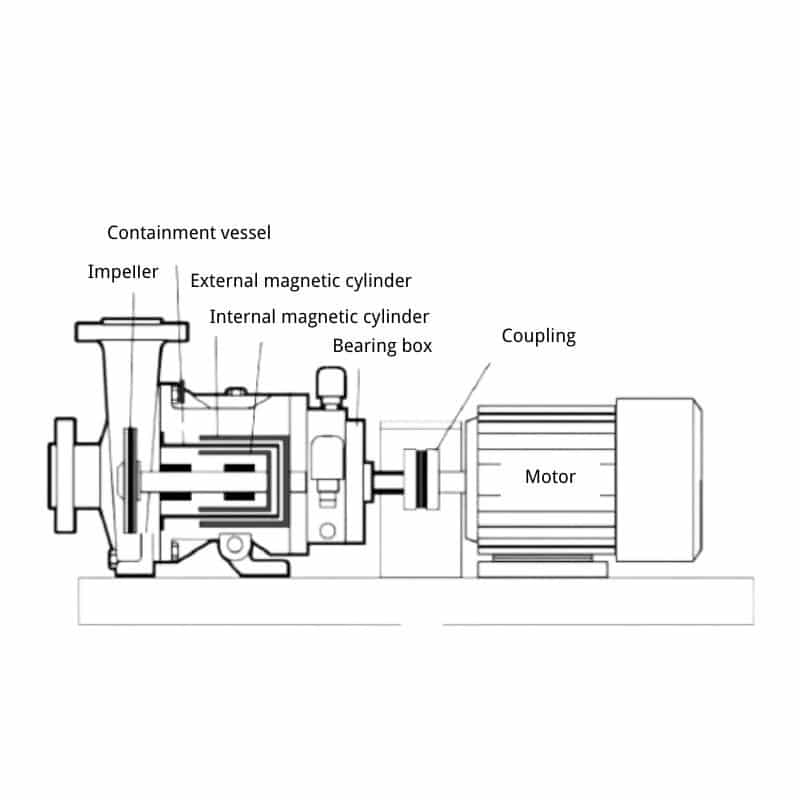

Working principle of magnetic drive pumps

The operating principle of the magnetic drive pump is based on the basic principles of magnetic transmission and contactless drive. It transfers energy through an internal magnetic coupling, enabling the pump to operate without mechanical seals or direct contact. Specifically, a magnetic drive pump consists of a magnetic field generated by an external motor and an internal magnetic rotor. When the external motor drives the rotor to rotate, the internal magnetic rotor rotates with it, thus transferring energy to the impeller or the part of the pump that pushes the liquid. This contactless drive eliminates sealing problems that can occur in traditional pumps, reducing the risk of leakage and improving the reliability and safety of the pump.

Structure of magnetic drive pumps

The structure of the magnetic drive pump is mainly composed of an external motor, a magnetic drive device and a pump body. The magnetic field generated by the external motor is transferred to the inside of the pump body through the magnetic drive unit to drive the pump. This design eliminates the mechanical bearings and sealing components found in conventional pumps, thus avoiding direct contact and possible risk of leakage inside the pump body.

Magnetic drive pump operation

- The external motor generates a magnetic field, which is transmitted to the inside of the pump body by a magnetic drive.

- The magnetic rotor inside the pump body is rotated by the magnetic field.

- The rotation of the magnetic rotor drives the impeller inside the pump or pushes the liquid part, realizing the suction and discharge of liquid.

This magnetic drive enables the operation of the pump without the need for a direct mechanical connection, thus eliminating the leakage and contamination problems that can occur in conventional pumps, and improving the reliability and safety of the pump.

Advantages of magnetic drive pumps

Magnetic drive pumps have several advantages over conventional pumps:

- Leak-free design: Magnetic drive pumps use magnetic drive to realize operation without mechanical seals, thus eliminating the leakage problems that may occur in traditional pumps and reducing the risk of environmental pollution.

- High safety: Due to the leak-free design, magnetic drive pumps are particularly suitable for scenarios where corrosive, toxic, or flammable liquids are handled, improving the safety of the working environment.

- Low maintenance costs: Magnetic drive pumps eliminate the need for routine mechanical seal maintenance, reducing maintenance and downtime and lowering maintenance and operating costs.

- Environmentally sustainable: the leak-free design of magnetic drive pumps not only reduces pollution to the environment but also improves system reliability and operational efficiency, in line with the requirements of environmentally sustainable development.

AOBL’s MP series, MPH series, CQF series, and CQF-Z series are all characterized by shaft seal-less design, completely sealed and leakage-free, conveying various corrosive liquids with different maximum flow rates and application ranges. If you need, you can contact us anytime.

Limitations and problems with magnetic drive pumps

- Higher cost: Magnetic drive pumps have a higher initial investment cost compared to conventional pumps. This is mainly due to the higher cost of advanced processes and materials required for magnetic drive technology and leak-free design.

- Restricted flow range: The flow range of magnetic drive pumps may be somewhat restricted due to the limitations of the magnetic drive. Particularly for application scenarios with high flow requirements, larger sizes of magnetic drive pumps may be required, increasing cost and installation space requirements.

- Need for precision manufacturing: The manufacturing process of magnetic drive pumps requires a higher degree of precision and workmanship, including the precise matching of the magnetic rotor and pump body, as well as the guarantee of sealing performance. This can increase manufacturing costs and place higher demands on the production process.

Application areas of magnetic drive pumps

- Chemical industry: Magnetic drive pumps are suitable for chemical processes that handle corrosive, toxic, or flammable liquids, such as acids, alkalis, and solvents. They are commonly used in chemical production processes such as conveying, circulating, and stirring processes.

- Pharmaceutical industry: In pharmaceutical processes, there is a high demand for fluid-tightness to avoid cross-contamination and drug loss. The leak-free design of magnetic drive pumps makes them ideal for handling medicinal fluids, solvents, biochemicals, and more.

- Food processing industry: In food processing, there are strict requirements for handling liquids and the need to ensure product safety and hygiene. Magnetic drive pumps can be used to convey food ingredients, beverages, sauces, etc. while avoiding the risk of leakage and contamination.

- Environmental protection industry: In the field of environmental protection, there is a need to deal with all kinds of wastewater, waste liquids, and harmful gases. Magnetic drive pumps can be used in sewage treatment, wastewater treatment, gas absorption, and other environmental protection processes with the advantages of no leakage, high safety, and low maintenance costs.

- Other fields: Magnetic drive pumps are also widely used in electronics, semiconductors, energy, aerospace, and other fields for the transportation and treatment of various liquids.

Summary

Magnetic drive pumps are widely used in the chemical, pharmaceutical, food processing, and environmental protection industries due to their leak-free design, high safety, and low maintenance costs. Despite their high initial investment cost and limited flow range, magnetic drive pumps show unique value and application prospects in handling corrosive, toxic, or flammable liquids, and in industrial scenarios that require a high degree of sealing and safety.

AOBL is committed to providing customers with a full range of pump solutions. In addition to magnetic drive pumps, we offer pneumatic diaphragm pumps, electric diaphragm pumps, sanitary diaphragm pumps, progressive cavity pumps, vertical centrifugal pumps, and chemical pumps. Whatever your needs, we can provide high-quality, reliable, and high-performing pumps to meet your application requirements.