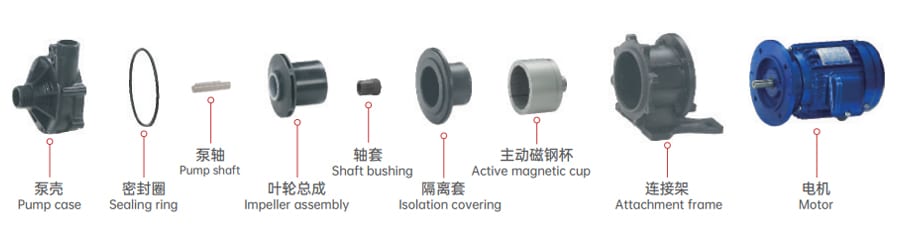

MPH series magnetic pumps are designed to maximize performance and improve product durability due to their innovative energy-saving design. Maximum flow rates from 150 liters per minute to 1400 liters per minute. The overflow parts are made of reinforced polypropylene plastic, and the pump shaft, bearings and end rings are made of highly corrosion-resistant materials. The pump shaft, bearings and end rings are made of highly corrosion-resistant materials. Such as: ceramic, filled PTFE, carbon. This ensures safe transportation of most chemical fluids.

Maximum Flow: 1400 LPM

Maximum Head: 30 m

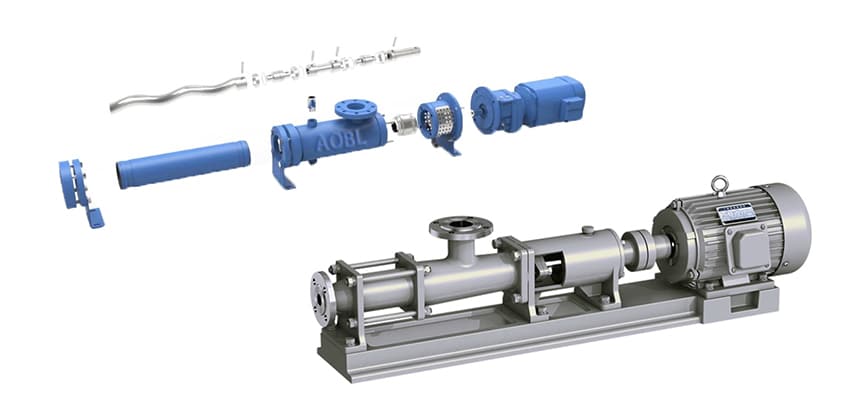

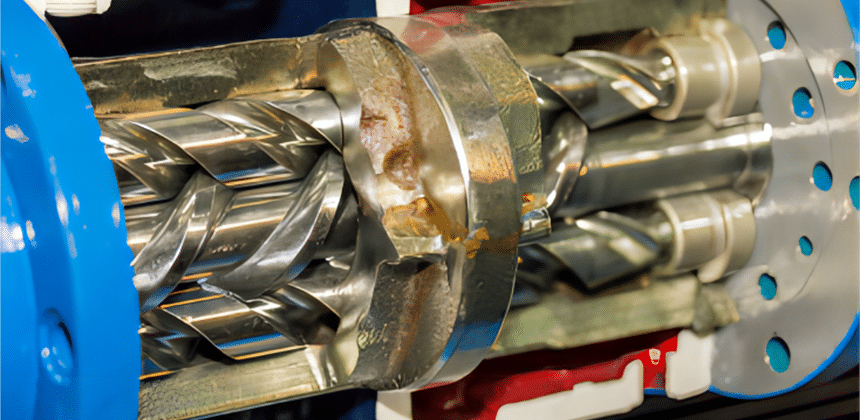

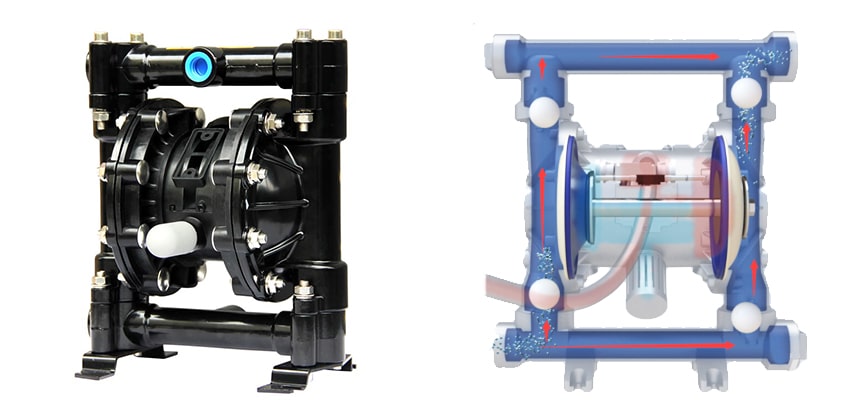

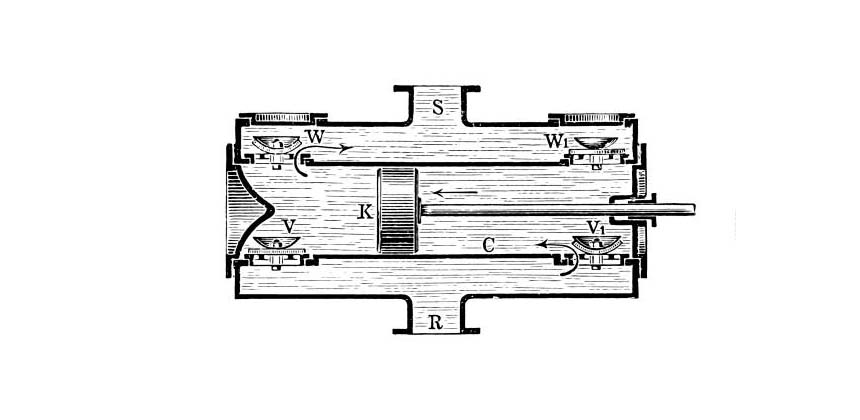

AOBL MPH series magnetic pump adopts no shaft seal design, which completely solves the disadvantages of running, bubbling, dripping and leaking that cannot be avoided by the traditional mechanical shaft seal pump. Optimized structure design plastic parts are reinforced with glass fiber. The impeller and magnetic inner rotor are injection molded as a whole, which reduces the volume of pump components and greatly improves the efficiency of the pump. volume, greatly improving the efficiency of the pump.

Features

- Excellent acid and alkali resistance

Pump body material is optional, high quality acid and alkali resistant material ensures the transportation of all kinds of chemical liquids. - Corrosion resistance

The main components of the pump have good corrosion resistance. - Unique bearing design, dry running resistance

Due to the unique design of the bearing, the fluid circulates and cools with the impeller, main shaft and magnetic bladder during the normal operation of the pump. Although the pump runs dry, the temperature cannot rise quickly enough to avoid serious damage to the pump. - Easy to assemble

The internal parts of the magnetic drive seal-less pump are completely standardized and easy to assemble Completely constructed with high performance. Replacement of parts is easy and does not require any special tools. - Maximum Durability

The use of ultra-powerful permanent magnets provides excellent performance and coupling capability. - Versatile applications

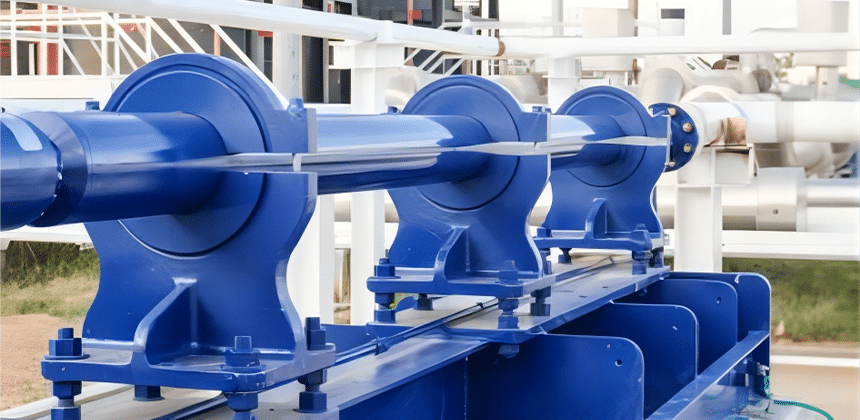

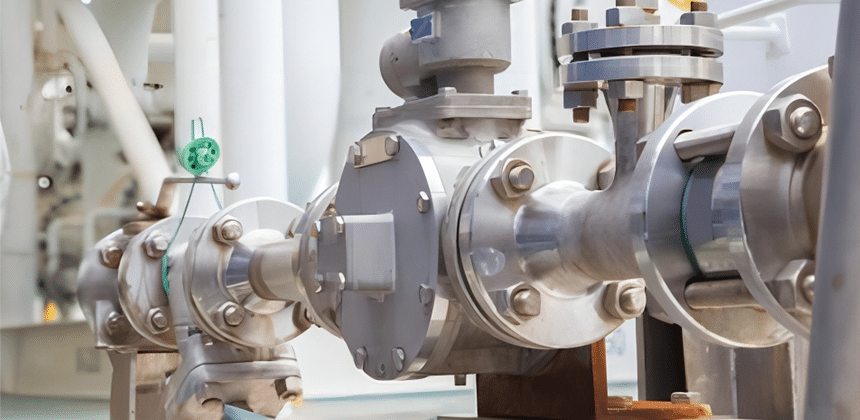

Ideal for low flow high head or high flow low head applications. Widely used in various industrial processes. Such as PCB manufacturing process, chemical industry, recirculation filtration, etching, electroplating, surface treatment, wastewater treatment, etc.

| Brand | AOBL |

| Maximum flow | 150 LPM – 1400 LPM |

| Maximum head | 8.5 m – 30 m |

| Motor power | 0.37 kW – 7.5 kW |