Industrial Pumps

Industrial pumps are a type of fluid transfer equipment specially designed for use in various industrial applications. These pumps can be used to transfer liquids, gases, slurries, or suspensions and play a key role in industrial production. They are used in various industries including chemical, oil and gas, pharmaceutical, food and beverage, water treatment, pulp and paper, energy, and power.

How does it work?

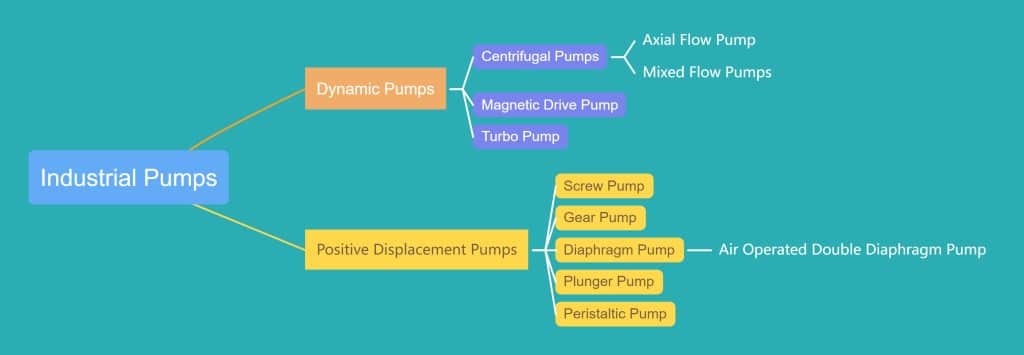

The types of industrial pumps are divided into two main categories: dynamic pumps and positive displacement pumps.

Dynamic pumps utilize the rotation of an impeller or propeller to transfer kinetic energy to the liquid, so that the liquid gains kinetic energy and pressure, thus conveying it to its destination.

Positive displacement pump is a pump that sucks in and discharges liquid by changing the volume of the pump chamber so that the liquid generates pressure.

Types of industrial pumps

Dynamic pumps

Centrifugal pump

A centrifugal pump is a mechanical device that utilizes centrifugal force generated by a rotating impeller to move fluid. It is the most common and widely used type of industrial pump for a variety of liquid transfer applications. Centrifugal pumps have mechanical or packing seals to prevent leakage of liquid along the pump shaft.

Mixed flow pumps combine the characteristics of centrifugal and axial flow pumps. The path of the liquid in the pump has both radial and axial components. The impeller is designed so that the liquid is subjected to both centrifugal force and axial thrust, thus realizing efficient conveying.

Abaxial flow pumps generate axial thrust through the rotation of the impeller, which moves the liquid in a direction parallel to the pump shaft. The liquid enters from the inlet of the pump, flows through the impeller in the axial direction, and is discharged from the outlet.

Magnetic drive pump

Magnetic drive pumps are pumps that utilize magnetic coupling to transmit power without the need for traditional mechanical shaft seals. With no moving seals, these pumps offer higher reliability and lower risk of leakage and are widely used to handle hazardous, corrosive, and valuable liquids in industries such as chemical, pharmaceutical, food and beverage, water treatment, and oil and gas.

Turbo pump

Turbo Pump is a high-speed rotating mechanical pump that accelerates and compresses gas molecules through a series of high-speed rotating impellers and stator vanes to achieve gas extraction and is widely used in applications requiring high vacuum and high pumping speed. Most turbopumps have an oil-free design, which avoids oil contamination and improves the cleanliness of the vacuum system. Their design and operating characteristics make them important in semiconductor manufacturing, scientific research and experimentation, aerospace, and a variety of high-precision fields.

Positive displacement pumps

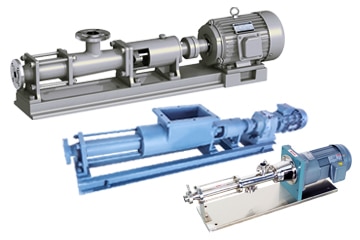

Screw pump

Screw pumps work by a screw rotating in the pump chamber, seals and bearings prevent liquid leakage and support the screw rotating shaft, forming a continuous sealing chamber that pushes the liquid from the inlet to the outlet of the pump, which is friendly to sensitive liquids and shear-sensitive media due to low shear forces. They are suitable for conveying liquids with high viscosity, solid particles and sensitive media, and are widely used in a variety of industrial applications due to their smooth flow and efficient conveying capacity.

Gear pump

A gear pump is a positive displacement pump that captures and conveys liquid through the rotation of two meshing gears. The pump casing contains the gears and the liquid flow casing, which provides sealing and support. Gear pumps have good self-priming capability and do not require pre-filling of the pump. Able to handle liquids containing small amounts of particulate matter, good wear resistanceSimple design and compact structure, widely used in, various industrial fields, especially in the need to transfer high viscosity liquids.

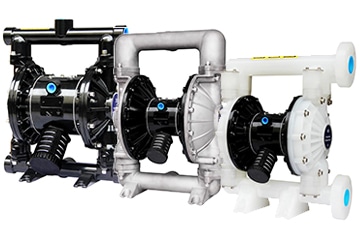

Diaphragm pump

Diaphragm pumps utilize the reciprocating motion of diaphragms to propel liquids. Due to their advantages of being leak-free, corrosion-resistant and self-priming, they are widely used in applications that require high reliability and safety, such as the chemical, pharmaceutical, food processing and wastewater treatment industries. Among them, diaphragm pumps contain air operated double diaphragm pumps and electromagnetic diaphragm pumps, both designed for fluid transfer in various applications.

Plunger pump

Plunger pumps deliver liquids through the reciprocating motion of a plunger in the pump chamber and are capable of generating very high pressures for high pressure applications. Suitable for applications requiring precise dosage, due to their high pressure and high efficiency, plunger pumps are widely used in applications requiring high pressure and precise flow control, such as the petroleum, chemical, pharmaceutical and food industries.

Peristaltic pump

Peristaltic pumps are made by compressing a tube through a series of rollers, creating a moving pressure point; As the pressure point moves, it pushes the liquid through the tube while generating suction behind the pressure point to draw more liquid into the tube. They are widely used in applications that require contamination-free transportation, such as medical, food, chemical, and biotechnology.

Summary

Industrial pumps play a key role in modern industrial production, and their diverse designs and efficient operating principles enable them to meet the needs of a wide range of complex applications. Whether they are power or positive displacement pumps, each type of pump has its unique benefits and areas of application, ensuring the efficient and reliable transfer of liquids in all types of industrial applications.

AOBL has a leading technical research and development team dedicated to the production of high-quality pump products, choosing us is to choose the guarantee of high quality and performance. Whether for industrial applications or professional needs, we can provide the best pump solutions to help our customers achieve higher production efficiency and more stable operating results.