Newton’s Law of Viscosity

In pump selection and design, it is critical to understand the principles of Newton’s Law of Viscosity, which describes the relationship between the viscosity of a fluid and its shear rate. This law provides insight into fluid behavior and is important in engineering applications.

What is Newton’s law of viscosity?

Newton’s law of viscosity describes the relationship between the viscosity of a fluid and its shear rate.

In a Newtonian fluid, the shear stress is directly proportional to the shear rate. In other words, when a fluid is subjected to an externally applied shear force, its rate of deformation (shear rate) is proportional to the shear stress applied.

Newton’s Law of Viscosity Equation

τ= μ ⋅ γ

- τ denotes the shear stress.

- μ denotes the dynamic viscosity of the fluid.

- γ denotes the shear rate.

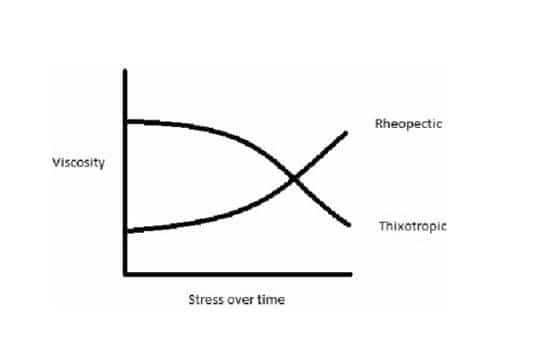

This law applies to Newtonian fluids, i.e., fluids with constant viscosity, such as water and air. In Newtonian fluids, the viscosity is unaffected by the shear rate, i.e., it remains constant regardless of the change in shear rate. Therefore, Newton’s law of viscosity is applicable to describe the flow behavior of such fluids. It is important to note that not all fluids qualify as Newtonian fluids, and some fluids, known as non-Newtonian fluids, have viscosities that change with shear rate.

Viscosity of Newtonian and Non-Newtonian Fluids

| Characteristics | Newtonian fluids | Non-Newtonian fluids |

| Is the viscosity constant | Viscosity remains constant. | Viscosity changes with change in shear rate. |

| Relationships | Shear stress is linearly related to shear rate. | The relationship between shear stress and shear rate is complex. |

| Example | Water, air, some liquid metals. | Milk, jam, particle suspensions, polymer solutions. |

How does Newton’s Law of Viscosity affect pumping?

Pump Selection: Since the viscosity of a Newtonian fluid remains constant at different shear rates, the viscosity characteristics of the fluid can be more accurately considered when selecting a pump to select the appropriate pump type and size.

Flow and Pressure Prediction: Newton’s Law of Fluid Viscosity makes it possible to more accurately predict changes in fluid flow and pressure in piping.

Pump Design: When designing a pump, the internal structure and components of the pump can be optimized according to the Newtonian fluid properties of the fluid to maximize pump efficiency and performance. For example, by optimizing the design of the impeller and pump casing, the resistance to the flow of the fluid inside the pump can be reduced, improving the pump suction and discharge efficiency.

The impact of Newton’s law of fluid viscosity on the pumping process is mainly in the areas of pump selection, design, flow, and pressure prediction.

Pumps Suitable For Conveying

Centrifugal Pumps: Centrifugal pumps are one of the most commonly used types of pumps for transferring Newtonian fluids such as water and air. They have a simple structure, high efficiency, and reliability, and are widely used in industrial and civil applications.

Plunger Pumps: Plunger pumps are also suitable for transferring Newtonian fluids, especially where high pressure and precision are required, such as in pressure testing and chemical filling.

Screw Pumps: Screw pumps are characterized by continuous delivery, low pulsation, and adaptability, and are suitable for transferring water, oil, and other Newtonian fluids.

Diaphragm Pumps: Diaphragm pumps compress and release diaphragms to transfer fluids and are suitable for transferring water, chemicals, and other fluids. The KES40 diraphragm pump is lightweight and versatile enough to handle aggressive fluids and small suspended solids. The rugged construction features a thick-walled injection molded fluid housing and cast iron or aluminum center section to withstand various demanding industrial applications.

It is critical to consider the viscosity of the fluid in the pump selection process. Newton’s Law of Viscosity provides a basic framework to help us understand the behavior of different fluids and make appropriate decisions in pump selection and design. By fully understanding Newton’s Law of Fluid Viscosity, we can better select the type of pump and materials that are appropriate for a particular fluid, ensuring pump performance and stable operation.